Posts on the Topic Alloys

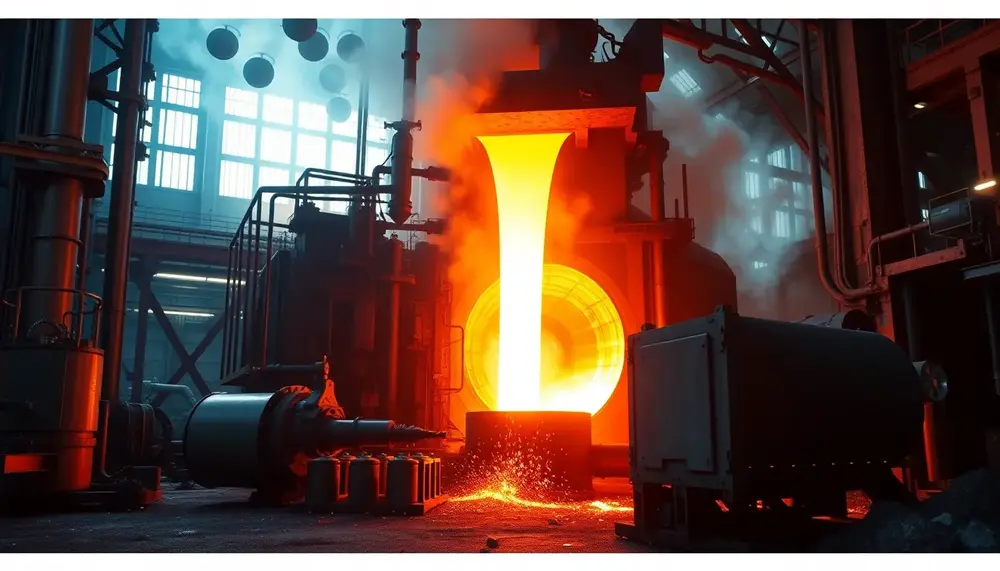

Vacuum Tank Degassing (VTD) revolutionizes steelmaking by delivering ultra-pure, high-performance steels with superior mechanical properties and process flexibility. Its adoption drives innovation across industries like automotive, energy, and medical devices while digital monitoring boosts efficiency and traceability....

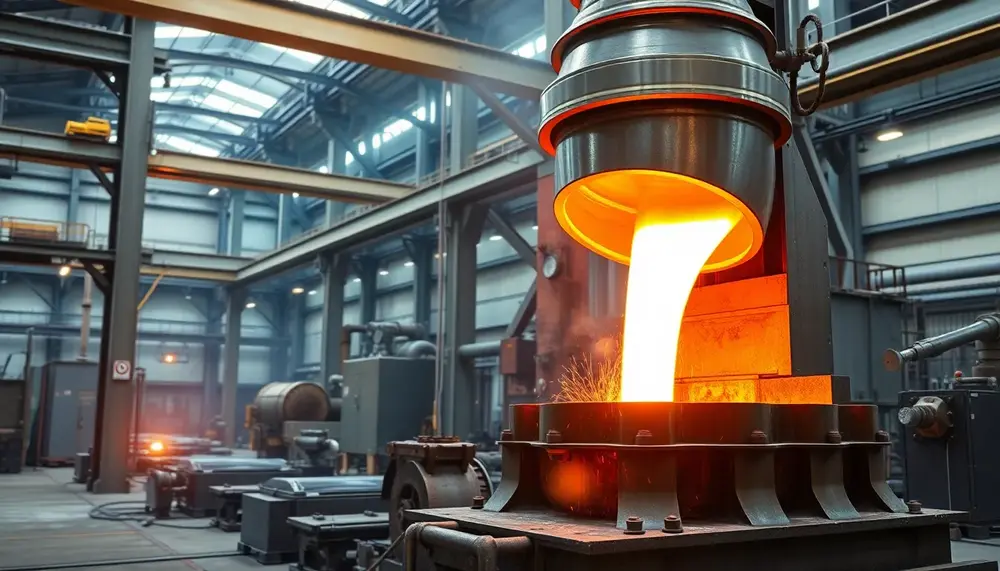

Converters are the core of modern steelmaking, rapidly transforming raw iron into high-quality steel through precise oxygen blowing and advanced process control. Their evolution—from Bessemer’s air-blown vessel to today’s digitally monitored systems—enables flexible, efficient production that meets diverse industrial demands....

Vacuum Induction Melting (VIM) revolutionizes steel-making by enabling ultra-pure alloys through precise melting, impurity removal in a vacuum, and real-time composition control. Recent innovations like advanced monitoring systems, hybrid techniques, and energy-efficient designs enhance material quality while promoting sustainability for...

Steel production is a complex process combining traditional methods and modern technology to transform raw materials into versatile, durable products essential for industries like construction, automotive, energy, and consumer goods. Its adaptability ensures steel remains vital in innovation and sustainable...

Steelmaking combines science and engineering to transform raw materials into tailored steel products through precise control of temperature, composition, and reactions. Its evolution reflects human innovation, from ancient smelting techniques to modern sustainable methods driven by advanced theoretical principles like...

The KOBM steelmaking process, known for its combined oxygen blowing technique, enhances efficiency and quality by offering precise control over chemical composition, flexibility in producing various steel grades, reduced environmental impact, and cost-effectiveness compared to traditional methods....

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...

Steel is a versatile material essential to modern industry, with various grades tailored for specific uses from construction to technology. Its key advantages include durability, resistance to extreme conditions, and recyclability, making it integral in innovation and sustainability efforts across...

The surge in steel product demand is driven by global economic growth, urbanization in emerging economies, sustainable construction practices, renewable energy projects, and technological advancements. Key factors include infrastructure investment, advanced steel grades for sustainability, developed countries' infrastructure renewal, and...