Posts on the Topic Furnace

Steelmaking nouns are essential for clear communication and safety in the steel industry, with evolving terminology requiring an up-to-date glossary. This article explains key terms like alloy, arc furnace, austenite, blast furnace, billet, basic oxygen process, carbon content, converter, casting,...

IspatGuru is a comprehensive resource for understanding steelmaking, offering insights into foundational concepts, advanced technologies like BOF and EAF processes, and sustainability. It bridges theory with practical applications while addressing modern challenges such as efficiency, environmental impact, and innovation in...

The evolution of steelmaking in America reflects centuries of innovation, from colonial ironworks to modern high-tech factories, driven by technological breakthroughs and economic demands. Key milestones like the Bessemer process and basic oxygen furnaces revolutionized production efficiency, solidifying steel's role...

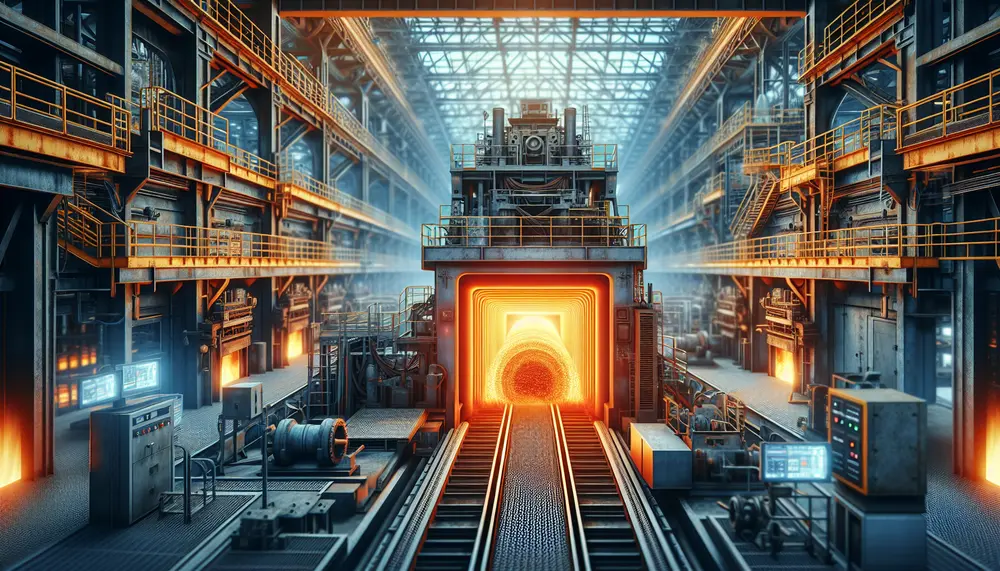

The article explores the steel industry's complexity, highlighting PDFs as essential guides for understanding processes like raw material preparation, ironmaking, and refining. It emphasizes the blast furnace's critical role in transforming raw materials into molten iron through efficient chemical reactions...

The article emphasizes the importance of visually presenting the steel manufacturing process through engaging PowerPoint slides, breaking down complex steps like raw material preparation and blast furnace operations using diagrams, animations, and concise text to enhance understanding for diverse audiences....

The article provides a detailed overview of the steelmaking process, highlighting key components like raw materials, energy sources, and advanced technologies. It explains primary methods (BOF and EAF), step-by-step production stages, and emphasizes sustainability and innovation in modern steel manufacturing....

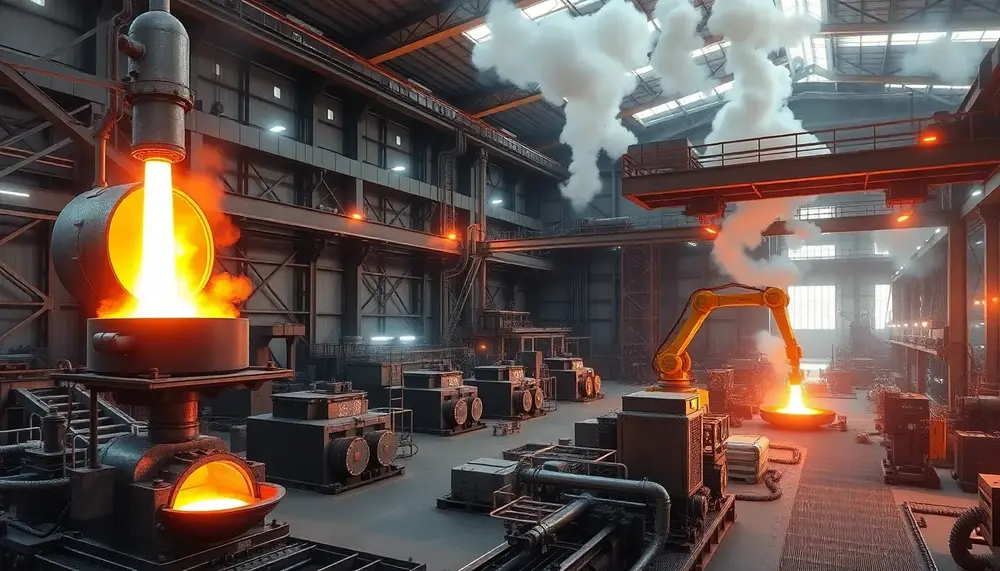

Steel making induction furnaces revolutionize the industry by providing controlled, energy-efficient methods for melting and refining steel through electromagnetic induction. These furnaces offer key advantages such as precise temperature control, reduced emissions, faster melting times, versatility in metal types, and...

The article explains the differences between steelmaking coal and thermal coal, highlighting their distinct uses in industry—steel production for steelmaking coal and electricity generation for thermal coal. It also discusses the importance of understanding these distinctions for businesses involved in...