Posts on the Topic Oxygen

Vacuum Tank Degassing (VTD) revolutionizes steelmaking by delivering ultra-pure, high-performance steels with superior mechanical properties and process flexibility. Its adoption drives innovation across industries like automotive, energy, and medical devices while digital monitoring boosts efficiency and traceability....

Steelmaking nouns are essential for clear communication and safety in the steel industry, with evolving terminology requiring an up-to-date glossary. This article explains key terms like alloy, arc furnace, austenite, blast furnace, billet, basic oxygen process, carbon content, converter, casting,...

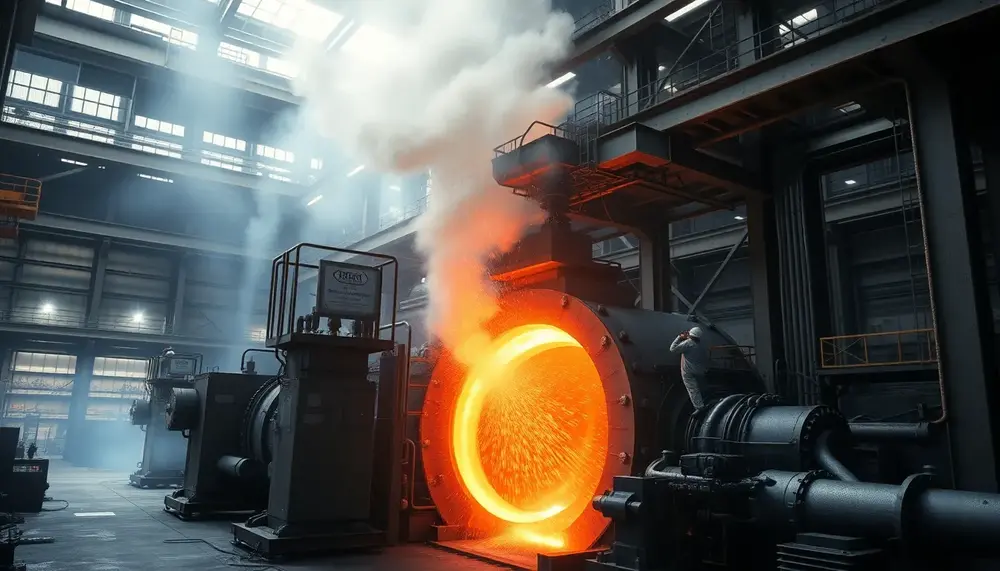

Converters are the core of modern steelmaking, rapidly transforming raw iron into high-quality steel through precise oxygen blowing and advanced process control. Their evolution—from Bessemer’s air-blown vessel to today’s digitally monitored systems—enables flexible, efficient production that meets diverse industrial demands....

IspatGuru is a comprehensive resource for understanding steelmaking, offering insights into foundational concepts, advanced technologies like BOF and EAF processes, and sustainability. It bridges theory with practical applications while addressing modern challenges such as efficiency, environmental impact, and innovation in...

Henry Bessemer revolutionized steel production in the 19th century with his innovative process, enabling mass production of stronger, affordable steel and fueling industrial growth. By efficiently removing impurities through oxygen blasts, his method drastically reduced costs and transformed steel into...

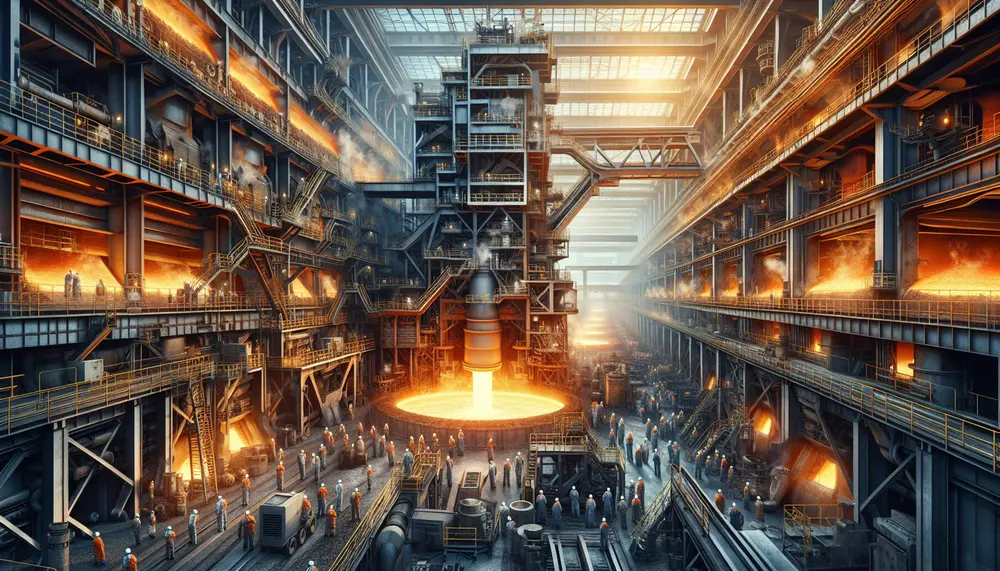

The article explores global steel production, focusing on the Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF) methods, highlighting their processes, environmental impacts, and adaptability. It emphasizes how sustainability trends are reshaping these techniques while secondary steelmaking refines quality...

The oxygen steelmaking process revolutionized the industry by efficiently producing high-quality steel through pure oxygen blowing, significantly reducing production time and costs. Key components include a converter, an oxygen lance for impurity removal, refractory lining protection, and slag formation to...

The Argon Oxygen Decarburization (AOD) process is essential in producing high-quality stainless steel by refining molten steel to reduce carbon content while preserving valuable alloying elements like chromium. This method, involving precise control of gas mixtures and temperatures during decarburization,...

The evolution of steelmaking has progressed from labor-intensive early methods to advanced technologies like the Basic Oxygen Steelmaking and Electric Arc Furnaces, enhancing efficiency and sustainability. The once-dominant Bessemer Process was superseded due to its limitations in controlling chemical composition...

The article discusses the significance of names in steel manufacturing processes, which often reflect their inventors, locations, or characteristics and serve as a historical timeline of industry advancements. It also outlines how terminology has evolved with technology and globalization, providing...