Table of Contents:

Introduction: Why Choosing the Right Equipment Manufacturer Matters

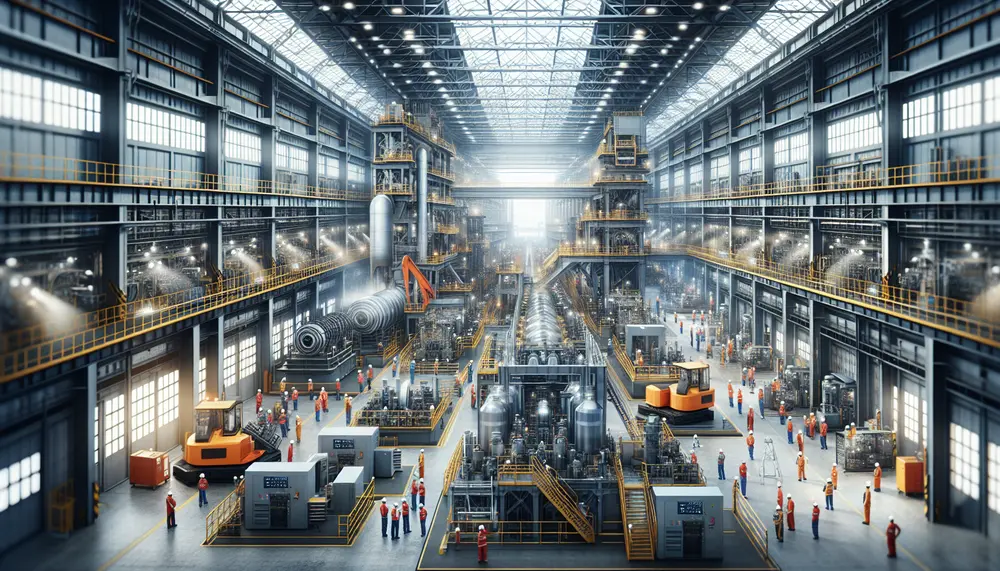

Choosing the right steel making equipment manufacturer is crucial for the success of your steel production operations. The right manufacturer can provide high-quality equipment that ensures efficiency, reliability, and safety in your production processes. On the other hand, a poor choice can lead to frequent breakdowns, increased maintenance costs, and even safety hazards.

By selecting a reputable manufacturer, you can benefit from advanced technology, innovative solutions, and comprehensive support services. This not only enhances your production capabilities but also helps you stay competitive in the market. In this article, we will explore the key considerations to keep in mind when choosing a steel making equipment manufacturer.

Assessing Experience and Reputation

When selecting a steel making equipment manufacturer, it's essential to assess their experience and reputation in the industry. Manufacturers with a long history in the steel production sector are more likely to have refined their processes and products over time. This experience often translates into higher quality and more reliable equipment.

Reputation is equally important. A manufacturer with a strong reputation is typically known for delivering on their promises and providing excellent customer service. To gauge a manufacturer's reputation, consider the following steps:

- Check online reviews and testimonials from other steel producers.

- Ask for references and contact previous clients to get firsthand feedback.

- Look for industry awards or recognitions that highlight their achievements.

By thoroughly assessing a manufacturer's experience and reputation, you can make a more informed decision and choose a partner that will support your production needs effectively.

Evaluating Product Range and Quality

Another critical factor in choosing the right steel making equipment manufacturer is evaluating their product range and quality. A manufacturer that offers a wide variety of equipment can meet diverse production needs and adapt to different operational requirements. This flexibility is crucial for optimizing your steel production processes.

Quality is paramount when it comes to steel making equipment. High-quality equipment ensures durability, efficiency, and safety. To evaluate the quality of a manufacturer's products, consider the following:

- Request product samples or visit their production facilities to inspect the equipment firsthand.

- Check for industry certifications that attest to the quality and safety standards of their products.

- Review technical specifications and compare them with industry benchmarks.

By thoroughly evaluating the product range and quality, you can ensure that the equipment you invest in will meet your production needs and stand the test of time.

Considering Technology and Innovation

In the rapidly evolving field of steel production, staying ahead of technological advancements is crucial. When choosing a steel making equipment manufacturer, it's important to consider their commitment to technology and innovation. Manufacturers that invest in research and development are more likely to offer cutting-edge solutions that enhance efficiency and productivity.

To assess a manufacturer's focus on technology and innovation, consider the following:

- Examine their investment in research and development (R&D) and their track record of introducing new technologies.

- Look for partnerships with leading technology providers or academic institutions.

- Check if they offer advanced features such as automation, data analytics, and energy-efficient designs.

By prioritizing technology and innovation, you can ensure that your steel production processes remain competitive and future-proof.

Understanding Customization Capabilities

Every steel production facility has unique requirements, and off-the-shelf solutions may not always meet your specific needs. Therefore, it's essential to understand a steel making equipment manufacturer's customization capabilities. A manufacturer that offers tailored solutions can adapt their equipment to fit your exact specifications, ensuring optimal performance and efficiency.

To evaluate a manufacturer's ability to provide customized equipment, consider the following:

- Discuss your specific needs and see if they can design equipment that meets those requirements.

- Ask for examples of past customization projects and the outcomes achieved.

- Check if they have a dedicated team for custom engineering and design.

By choosing a manufacturer with strong customization capabilities, you can ensure that your equipment is perfectly suited to your production processes, leading to better results and higher efficiency.

Prioritizing Customer Support and Service

Excellent customer support and service are vital when selecting a steel making equipment manufacturer. Even the best equipment can encounter issues, and having reliable support can minimize downtime and keep your operations running smoothly. A manufacturer that prioritizes customer service will be responsive and proactive in addressing your needs.

To evaluate a manufacturer's customer support and service, consider the following:

- Check their availability for technical support, including response times and service hours.

- Inquire about the availability of training programs for your staff to ensure proper equipment use and maintenance.

- Look for a dedicated customer service team that can provide personalized assistance and solutions.

By prioritizing customer support and service, you can ensure that you have a reliable partner to assist you throughout the lifecycle of your equipment, from installation to maintenance and beyond.

Considering Cost and Value

While cost is an important factor when choosing a steel making equipment manufacturer, it should not be the sole consideration. It's crucial to evaluate the overall value that the manufacturer provides. This includes the quality of the equipment, the level of customer support, and the potential for long-term savings through increased efficiency and reduced maintenance costs.

To assess cost and value effectively, consider the following:

- Compare the initial purchase price with the expected lifespan and durability of the equipment.

- Evaluate the total cost of ownership, including maintenance, repairs, and operational efficiency.

- Consider any additional services or warranties that may add value to your investment.

By focusing on both cost and value, you can make a more informed decision that balances your budget with the long-term benefits of high-quality, reliable equipment.

Evaluating Delivery and Installation Support

Timely delivery and proper installation are crucial when investing in steel making equipment. Delays or improper setup can disrupt your production schedule and lead to costly downtime. Therefore, it's important to evaluate the delivery and installation support offered by the manufacturer.

To assess their capabilities in this area, consider the following:

- Check their track record for on-time deliveries and ask for references from other clients.

- Inquire about their installation process, including the qualifications of their installation team.

- Ensure they provide comprehensive installation services, including setup, calibration, and initial testing.

By thoroughly evaluating delivery and installation support, you can ensure a smooth transition to new equipment, minimizing disruptions and maximizing productivity from day one.

Analyzing After-Sales Service and Maintenance

After-sales service and maintenance are critical aspects to consider when choosing a steel making equipment manufacturer. Reliable after-sales support ensures that your equipment remains in optimal condition, reducing the risk of unexpected breakdowns and extending its lifespan.

To analyze a manufacturer's after-sales service and maintenance offerings, consider the following:

- Check if they offer regular maintenance programs and what these programs include.

- Inquire about the availability of spare parts and the speed of their delivery.

- Ask about their service agreements and whether they provide on-site support or remote diagnostics.

By thoroughly analyzing after-sales service and maintenance, you can ensure that your investment is protected and that your equipment continues to operate efficiently over the long term.

Reviewing Regulatory Compliance and Certifications

Regulatory compliance and certifications are essential factors when selecting a steel making equipment manufacturer. Compliance with industry standards ensures that the equipment meets safety, environmental, and quality requirements. Certifications can also be a testament to the manufacturer's commitment to excellence.

To review a manufacturer's regulatory compliance and certifications, consider the following:

- Check for certifications from recognized industry bodies, such as ISO (International Organization for Standardization) or CE (Conformité Européenne).

- Ensure that the equipment complies with local and international safety and environmental regulations.

- Ask for documentation or proof of compliance and certifications during your evaluation process.

By reviewing regulatory compliance and certifications, you can be confident that the equipment you purchase adheres to the highest standards, ensuring safety and reliability in your production processes.

Conclusion: Making an Informed Decision

Choosing the right steel making equipment manufacturer is a critical decision that can significantly impact your production efficiency, safety, and overall success. By carefully considering factors such as experience, reputation, product range, quality, technology, customization capabilities, customer support, cost, delivery, installation, after-sales service, and regulatory compliance, you can make a well-informed choice.

Taking the time to evaluate these key considerations will help you select a manufacturer that not only meets your immediate needs but also supports your long-term goals. A reliable and innovative manufacturer can be a valuable partner in your steel production journey, ensuring that you stay competitive and efficient in a demanding industry.

Ultimately, an informed decision will lead to better performance, reduced downtime, and a higher return on investment, making it well worth the effort to thoroughly assess your options.

FAQs for Selecting the Best Steelmaking Equipment Manufacturer

Why is it important to assess the experience and reputation of a manufacturer?

Assessing the experience and reputation of a manufacturer is crucial because experienced companies are more likely to have refined their processes and products over time. A strong reputation indicates reliability, quality, and excellent customer service, helping you make an informed decision.

What should I look for in a manufacturer's product range and quality?

When evaluating a manufacturer's product range and quality, ensure they offer a variety of equipment that can meet diverse production needs. Inspect samples, check for industry certifications, and compare technical specifications to ensure high durability, efficiency, and safety.

How can I evaluate a manufacturer's commitment to technology and innovation?

To evaluate a manufacturer's focus on technology and innovation, review their R&D investments, their track record of new technology introductions, partnerships with tech providers, and the availability of advanced features like automation and data analytics.

Why are customization capabilities important?

Customization capabilities are important because every steel production facility has unique requirements. A manufacturer that offers tailored solutions can adapt their equipment to fit specific needs, ensuring optimal performance and efficiency.

What should I consider regarding after-sales service and maintenance?

Consider a manufacturer's after-sales service and maintenance offerings, such as regular maintenance programs, spare parts availability, and service agreements. Reliable after-sales support ensures equipment remains in optimal condition, reducing the risk of unexpected breakdowns.