Table of Contents:

Understanding the Basics of Steel Making Materials

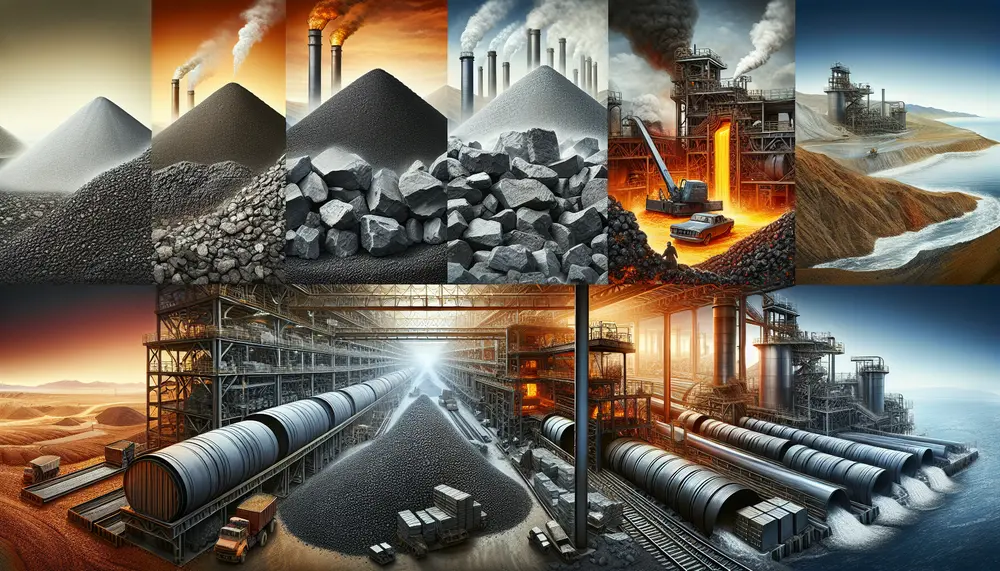

Understanding the Basics of Steel Making Materials involves comprehending the essential components and processes that transform raw elements into steel, a material indispensable in various industries. Steel making is an intricate process that requires specific raw materials, primarily iron ore, carbon (in the form of coke), and other elements such as chromium, nickel, and manganese which act as alloying agents to improve the properties of steel.

The journey begins with extracting iron ore, which is then purified and transformed into pig iron through a smelting process involving high temperatures in a blast furnace. The carbon sourced from coke (derived from coal) reacts with the ore, reducing it to produce molten iron while simultaneously removing impurities such as silicon, phosphorus, and sulfur. These impurities are essential to manage, as they affect the quality and usability of the final steel product.

Alloying elements are then introduced based on the type of steel desired. For example, increasing the amount of chromium and nickel enhances corrosion resistance, making it ideal for stainless steel applications. Every element added plays a crucial role in defining the strength, ductility, and overall structural integrity of the steel.

This foundational understanding paves the way for exploring the advanced processes and environmental impacts associated with steel production. The basic materials and their transformations are not just chemical reactions but are also guided by rigorous technology and significant energy inputs, making steel making both a science and an art.

Key Raw Materials Used in Steel Production

Key Raw Materials Used in Steel Production play critical roles in defining the efficiency, quality, and environmental footprint of the steel manufacturing process. Beyond iron ore and carbon, several other materials are essential in this complex production journey.

- Limestone: Often used as a flux in the smelting process, limestone aids in the removal of impurities by forming slag, which can be removed from the final product.

- Manganese: It acts as a deoxidizer and helps in preventing the formation of iron sulfide, enhancing the toughness and wear resistance of steel.

- Aluminum: Used in deoxidizing the molten steel and refining the grain size of the steel, which improves its quality and finish.

- Zinc: Primarily used in galvanizing steel to protect against corrosion, thereby extending the life of the product significantly.

Each of these materials affects the chemical and physical properties of steel, thereby influencing its suitability for various applications. Limestone, for instance, reacts with silicon dioxide to form calcium silicate, which appears as slag. The reactions can be represented by mathematical equations showcasing the involvement of these elements in steel processing:

| Material | Chemical Reaction |

|---|---|

| Limestone (CaCO3) | CaCO3 · heat → CaO + CO2 |

| Manganese (Mn) | 2 Mn + O2 · heat → 2 MnO |

| Aluminum (Al) | 2 Al + 3 O2 · heat → 2 Al2O3 |

The strategic use of these materials is foundational in achieving desired steel characteristics and in mitigating environmental impact, emphasizing the critical nature of raw materials in steel production.

The Role of Iron Ore in Steel Manufacturing

The Role of Iron Ore in Steel Manufacturing is pivotal, as it is the primary source of iron, which is the core component in steel production. The quality, type, and processing of the iron ore directly influence the properties and quality of the steel.

Iron ores are minerals from which metallic iron can be extracted. Principally composed of iron oxides, different ores include hematite (Fe2O3) and magnetite (Fe3O4). These ores undergo several processes to be converted into steel.

- Mining and Milling: Iron ore is extracted through mining and then milled to break it down into smaller pieces which are conducive for the next stages of processing.

- Beneficiation: This process enhances the iron content by removing impurities such as silica, which results in higher quality raw material for steel making.

- Pelletizing: Post beneficiation, iron ore fines are converted into pellets. These pellets are then fired in a furnace to create fired pellets with optimal properties for the blast furnace stage.

The chemical composition of ore affects its reduction behavior in the blast furnace. The reduced iron derived from these ores forms the raw material for steel making. The chemical transformations primarily involve the reduction of iron oxides to iron by carbon monoxide generated from burning coke:

Fe2O3 + 3 CO · heat → 2 Fe + 3 CO2

Iron ore not only serves as the backbone for the metallic base but also significantly affects the steel's durability, strength, and ability to withstand various environmental conditions. The proper selection and handling of this raw material are critical for the overall sustainability and quality of the steel produced, thus highlighting its indispensable role in steel manufacturing.

Coal and Coke: Essential for Heat and Reduction

Coal and Coke: Essential for Heat and Reduction in the steel manufacturing process, serve specific critical functions that facilitate the transformation from iron ore to steel. Coal is primarily used to produce coke, a porous, carbon-rich material that fuels the iron-making blast furnaces.

Coke is produced by heating coal in the absence of air, a process known as coking. This process drives off impurities to leave nearly pure carbon. Coke's properties allow it to perform effectively under the high temperatures and pressures of blast furnaces, which typically reach about 2000°C.

- High Temperature Fuel: Coke serves as a fuel to generate the necessary heat for melting iron ore.

- Chemical Reductant: Coke’s carbon content is essential in reducing iron ore to iron. It reacts with the oxygen in iron oxide, stripping it away and leaving behind metallic iron.

- Supporting Burden: The structural strength of coke supports the weight of iron ore and limestone charged into the blast furnace.

The chemical reactions that take place include the formation of carbon monoxide, which is crucial for reducing iron oxides to iron:

C + O2 · heat → CO2

CO2 + C · heat → 2 CO

These reactions highlight the dual role of coke not only as a source of energy but also as a reductive agent crucial for the separation of iron from its oxide form. The processed coke thus not only provides the heat required for melting but also participates in the chemical reduction necessary for producing raw iron. This dual functionality underscores the essential nature of coal and coke in producing high-quality steel.

Recycled Steel: Enhancing Sustainability in Steel Production

Recycled Steel: Enhancing Sustainability in Steel Production emphasizes the utilization of scrap steel, reducing the reliance on raw materials and minimizing environmental impact. Recycling steel not only conserves natural resources but also uses less energy compared to producing steel from virgin ore.

Recycled steel is integral in sustainable steel production, as it can be melted and reused in new products through processes like the Electric Arc Furnace (EAF). Here, scrap steel is melted using high-power electric arcs, offering a more energy-efficient alternative to traditional blast furnace methods.

- Energy Efficiency: Producing steel through recycling consumes approximately 60% less energy than producing steel from new materials.

- Resource Conservation: Using recycled materials drastically reduces the need for new raw materials, preserving valuable resources like iron ore and coal.

- Carbon Emission Reduction: Lower energy consumption translates into significant reductions in greenhouse gas emissions, supporting global efforts against climate change.

The cycle of melting down the scrap and reforming it into new steel requires careful control of impurities and alloy composition to ensure the quality and properties of the final steel product are up to standard. The following equations highlight some of the processes involved in recycling:

Scrap + Energy · heat → Molten Steel

Molten Steel + Alloying Elements · stir → Recycled Steel

Adopting recycled steel in manufacturing processes not only supports environmental stewardship but also enhances the industry's overall sustainability. It demonstrates a practical application of circular economy principles in heavy industries like steel production.

Technological Advances in Steel Making Processes

Technological Advances in Steel Making Processes have significantly transformed the efficiency, quality, and environmental footprint of steel production. Innovations range from improvements in furnace designs to automated control systems that fine-tune the chemical processes involved.

- Continuous Casting: This technology allows for the direct casting of molten steel into shapes that can be rolled or processed further, reducing energy and material waste compared to older batch processes.

- Near-net-shape Casting: Minimizes the need for further mechanical processing, decreasing energy consumption and improving yield efficiency.

- Advanced Furnace Technology: Developments such as Electric Arc Furnaces (EAF) that can melt scrap steel more efficiently and with lower CO2 emissions.

Automation and AI have also made pivotal contributions, enhancing precision in processes such as temperature and process control, which are crucial for ensuring the consistent quality of steel. Furthermore, these technologies facilitate predictive maintenance, preventing downtime and optimizing operation cycles:

Precise Temperature Control + AI Predictive Maintenance · optimize → Enhanced Efficiency and Lower Costs

Cleaner production techniques have also been paramount. Innovations such as hydrogen-based steel making are being explored as alternatives to traditional coal-based methods, aiming to reduce carbon emissions from the steel industry significantly.

Such technological advancements not only push the boundaries of what is possible in terms of production capacity and quality but also align the steel manufacturing industry with modern sustainability standards, reducing its environmental impact while enhancing product reliability and efficiency.

Environmental Impact of Steel Production

Environmental Impact of Steel Production is significant, given that the industry is one of the major contributors to global carbon dioxide (CO2) emissions, resource depletion, and energy consumption. However, continuous efforts and advancements aim to mitigate these impacts.

- Carbon Emissions: Traditional steelmaking processes, primarily those involving coal and coke, generate substantial quantities of CO2. Efforts to adopt cleaner energies and technologies are vital in reducing these emissions.

- Resource Use: Steel production is resource-intensive, consuming vast amounts of iron ore, coal, and water. Recycling steel plays a crucial role in reducing the demand for these raw materials.

- Water Usage: Significant amounts of water are required for cooling and processing steel, which poses challenges in water-scarce regions and impacts local ecosystems.

There are, however, proactive steps being taken to lessen these environmental impacts:

Development and implementation of CO2 capture and storage technologies · aim to decrease greenhouse gas emissions.

Increased use of Electric Arc Furnaces (EAF) that can melt recycled steel · reduces reliance on iron ore and coal, thereby lowering carbon output.

Water reclamation and recycling · minimize freshwater withdrawal and enhance water efficiency in the production process.

Enhancements in steel production not only focus on increasing operational efficiency but also emphasize ecological considerations, striving for a balance between industrial growth and environmental stewardship. These advancements are crucial for promoting sustainable practices within the steel industry, demonstrating a commitment to reducing its ecological footprint while maintaining production standards.

FAQ: The Steel Making Process Explained

What are the primary raw materials used in steel production?

The primary raw materials used in steel production are iron ore, carbon (in the form of coke), and various alloying elements like manganese, nickel, chromium, and zinc, which enhance the properties of steel.

How is iron ore transformed into steel?

Iron ore is first refined to produce pig iron in a blast furnace, which is then converted into steel in a steelmaking furnace like the Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF) through processes that reduce carbon content and add necessary alloying elements.

What role does coke play in steel production?

Coke, produced from coal, provides the high temperatures required in blast furnaces. It acts as a reducing agent to facilitate the chemical reactions that convert iron ore into iron and supports the burden of the raw materials in the furnace.

How does recycling impact steel production?

Recycling steel significantly reduces the demand for raw materials, lowers energy consumption by about 60% compared to new steel production, and diminishes CO2 emissions, enhancing the sustainability of the steel production process.

What technological advancements have improved steel manufacturing?

Technological advancements such as Electric Arc Furnaces (EAF), continuous casting, and automated control systems have enhanced the efficiency, quality, and environmental footprint of steel production, reducing energy consumption and emissions.