Annealing

Annealing

Willkommen zum Glossar Eintrag für den Begriff "Annealing" in unserem Online-Magazin über Steel production and steel trade. Wenn du dich schon immer gefragt hast, was "Annealing" im Kontext der Stahlproduktion und des Stahlhandels bedeutet, bist du hier genau richtig.

Was ist "Annealing"?

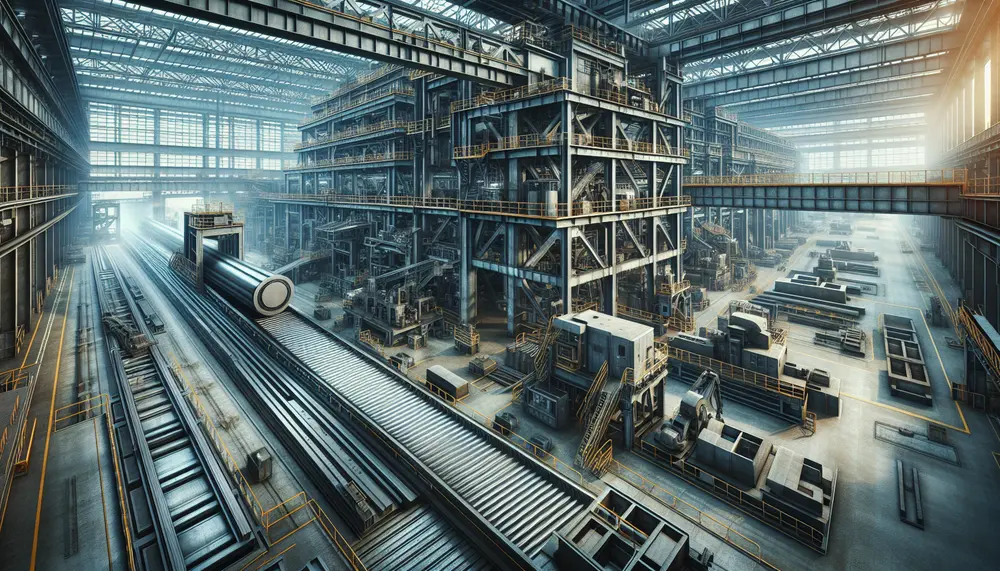

Annealing, zu Deutsch Glühen, ist ein wichtiger Prozessschritt in der Stahlproduktion und dem Stahlhandel. In der Industrie bezieht sich "Annealing" auf das Erhitzen eines Stahlobjekts auf hohe Temperaturen und das anschließende langsame Abkühlen. Der Hauptzweck dieses Prozesses besteht darin, die Härte des Stahls zu reduzieren und gleichzeitig seine Duktilität (Dehnbarkeit) zu erhöhen.

Warum ist "Annealing" in der Stahlproduktion wichtig?

Annealing spielt eine zentrale Rolle in der Stahlherstellung. Durch das Erhitzen des Metalls auf eine bestimmte Temperatur verändern sich die physikalischen und chemischen Eigenschaften des Stahls. Das hilft dabei, den Stahl flexibler und widerstandsfähiger gegen Risse zu machen. Dadurch wird die Qualität des Stahls verbessert, was für viele industrielle Anwendungen erforderlich ist.

Wie funktioniert der "Annealing"-Prozess?

Beim Annealing wird der Stahl auf eine Temperatur erhitzt, die höher ist als seine Umformtemperatur. Anschließend wird der Stahl für eine bestimmte Zeit gehalten, um sicherzustellen, dass eine gleichmäßige Temperatur im gesamten Stück erreicht wird. Schließlich wird der Stahl langsam abgekühlt, oft in der Ofenumgebung, bis er Raumtemperatur erreicht hat. Dieser Prozess führt zu einem weicheren, aber zäheren Stahl mit verbesserter Formbarkeit.

Zusammenfassung

Sie sehen, Annealing ist ein sehr wichtiger Prozess in der Stahlproduktion und im Stahlhandel. Es hilft nicht nur, die Qualität des Stahls zu verbessern, sondern sorgt auch dafür, dass das Metall die notwendige Flexibilität und Widerstandsfähigkeit besitzt, um für verschiedene industrielle Anwendungen geeignet zu sein.

Blog Posts with the term: Annealing

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

The steelmaking industry is increasingly using natural gas to improve efficiency and reduce environmental impact. Natural gas serves as a reducing agent in Direct Reduced Iron (DRI) processes, partially replaces coke in blast furnaces, fuels various types of industrial furnaces,...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

Steelmaking rolling is a crucial process that transforms raw steel into various usable forms by passing it through rollers to reduce thickness, improve uniformity, and achieve specific mechanical properties. The article details the stages of hot and cold rolling, the...

Steel making in Australia is crucial for the nation's infrastructure and economy, involving a two-stage process from iron ore to steel production using electric arc and basic oxygen furnaces. The industry has evolved over a century with technological advancements and...

JSW Steel employs advanced technology and sustainable practices in its steel manufacturing process, starting with the selection of raw materials like iron ore and coal. The company focuses on producing high-quality steel through a series of steps including melting, refining,...

Steel manufacturing from scrap is a sustainable process that reduces environmental impact and conserves resources. It involves collection, separation, melting in an electric arc furnace, refining to remove impurities, adding alloy elements, and casting into new products; recycling steel offers...

Steel is an iron-carbon alloy with varying carbon content that determines its hardness, ductility, and tensile strength; other elements like chromium can be added to enhance specific properties such as corrosion resistance. Steel products are categorized into four main types:...

The article provides a comprehensive guide to steel production, simplifying core concepts for beginners and detailing key processes such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) methods. It covers essential steps from ironmaking to finishing, offering...

Steel manufacturing is a complex, multi-stage process that transforms raw materials into the durable metal essential for modern infrastructure. It begins with extracting iron ore and progresses through various phases including blast furnace operation and primary steelmaking methods like Basic...

Modern steel factories combine advanced technology, automation, and strict quality control to transform raw materials into high-quality steel with precision and efficiency....

The concept of steelmaking grade is crucial in determining the quality and properties of steel, influencing efficiency, durability, and safety across various industries. Steel grades are classified based on chemical composition and production processes, with advancements in technology and global...

The article explores the steel industry's complexity, highlighting PDFs as essential guides for understanding processes like raw material preparation, ironmaking, and refining. It emphasizes the blast furnace's critical role in transforming raw materials into molten iron through efficient chemical reactions...