Coil

Coil

Was ist ein Coil?

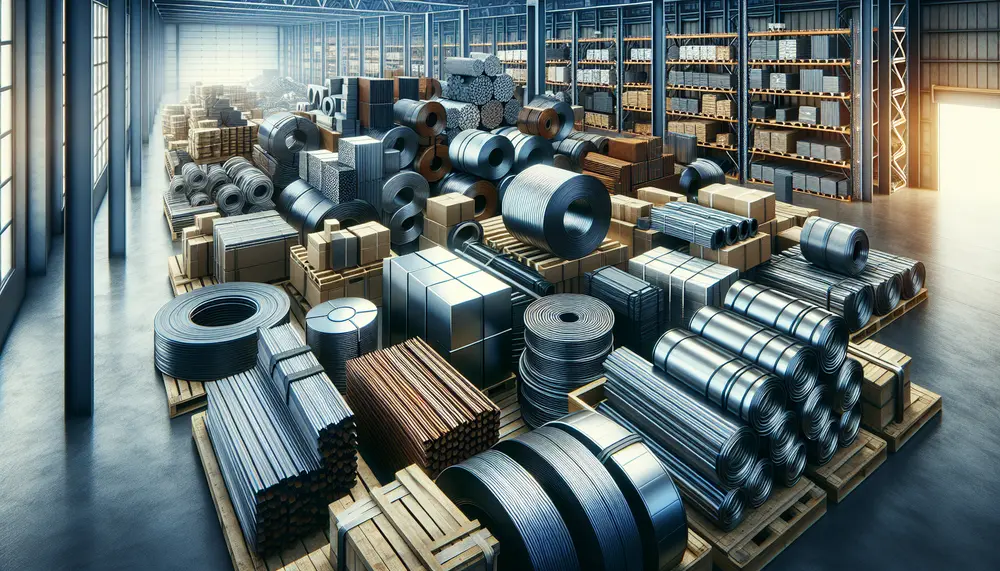

Ein Coil, im Kontext der Stahlproduktion und des Stahlhandels, ist ein Synonym für eine Rolle oder Spule, auf der die in flache Bahnen gewalzte Produkte aufgewickelt sind. Es handelt sich dabei konkret um eine Ausdrucksweise für den physischen Zustand einer Warenlieferung. Es ist eine gängige Art und Weise, dünne Bleche von Stahl oder andere Metalle für den Transport und die Lagerung zu verpacken.

Verwendung von Coils in der Stahlindustrie

Die Verwendung eines Coils in der Stahlindustrie hat mehrere Vorteile. Erstens erleichtert ein Coil das Handling und den Transport von großen Mengen an Stahl. Zweitens, indem der Stahl in einem Coil organisiert ist, lässt er sich leichter lagern, da er weniger Platz benötigt. Drittens, dient das Aufrollen auf ein Coil dazu, den Stahl vor der Einwirkung von Umwelteinflüssen zu schützen.

Coil Labels und Identifikationen

Jedes Coil enthält in der Regel ein Etikett mit den relevanten Informationen über Inhalt und Herkunft. Diese Informationen sind sehr wichtig für den Handel und auch für die weitere Verarbeitung. Dort sind z.B. Art des Metalls, Abmessungen, Gewicht, Materialart, Herkunft und weitere Informationen ablesbar.

Zusammenfassung

Ein Coil ist also nichts anderes als eine Rolle Stahl, die effizientes Handling und Schutz des Materials ermöglicht. Es ist eine grundlegende Einheit im Stahlhandel und in der Stahlproduktion und daher ist es wichtig, sich mit diesem Begriff vertraut zu machen.

Blog Posts with the term: Coil

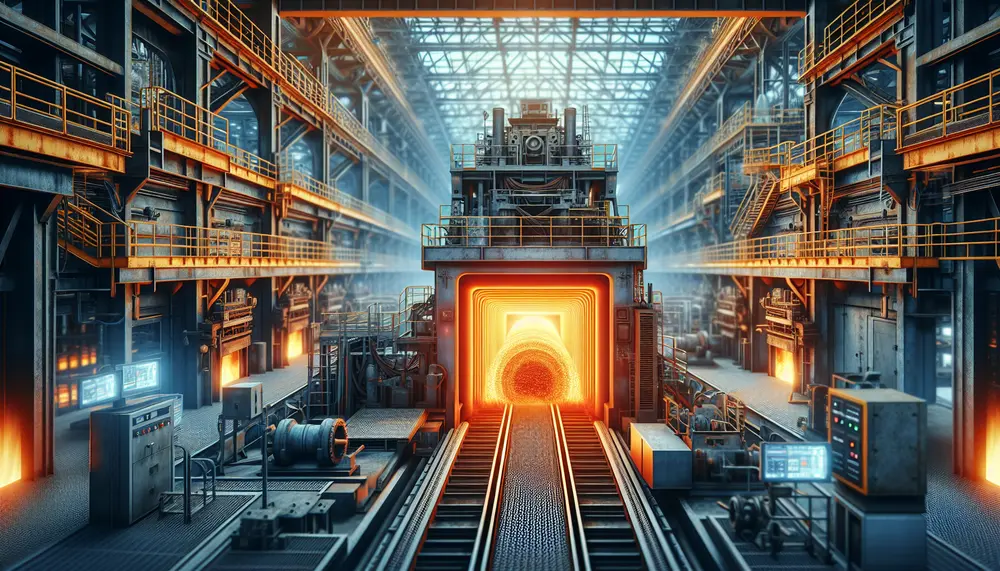

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

Induction furnaces have transformed steel making with their efficiency, versatility, and reduced environmental impact compared to traditional fossil fuel-based furnaces. They use electromagnetic induction for heating metals precisely and quickly, offering benefits like energy savings, improved productivity, metallurgical control, scalability,...

HTS codes are essential for classifying steel products in international trade, determining tariffs and compliance with regulations. They require precise understanding due to their complexity and frequent updates influenced by global trade changes....

The steel industry in Uganda is vital to its construction sector, supplying materials for infrastructure and buildings with a network of manufacturers, traders, suppliers, and regulators. Steel production meets local demand and exports; understanding the industry involves factors like raw...

The article explains the steel making process at SAIL Bokaro, highlighting its precision and adherence to quality and environmental standards. It details the journey from raw materials like iron ore, coal, and limestone through various stages including blast furnaces and...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

The UAE has experienced a significant increase in steel production, reflecting its broader economic diversification and sustainability goals. This growth is driven by strategic government policies, foreign investments, technological advancements, and the country's advantageous geographic location for exports....

Steelmaking rolling is a crucial process that transforms raw steel into various usable forms by passing it through rollers to reduce thickness, improve uniformity, and achieve specific mechanical properties. The article details the stages of hot and cold rolling, the...

The POSCO steel making process is a sophisticated combination of technology and environmental care, producing high-quality steel through efficient, innovative methods like the FINEX technology. This multi-stage production includes ironmaking, refining in a basic oxygen furnace during the converter phase,...

JSW Steel employs advanced technology and sustainable practices in its steel manufacturing process, starting with the selection of raw materials like iron ore and coal. The company focuses on producing high-quality steel through a series of steps including melting, refining,...

Steel tube manufacturing is essential for industries like construction, energy, and transportation, offering seamless tubes for strength and welded ones for cost-efficiency. The processes involve precise engineering to ensure durability, versatility, and performance tailored to specific applications....

A steel product is an item predominantly made of steel, known for its durability and versatility across industries, with a wide range of forms and applications. Understanding these products involves knowledge of the production process from raw materials to finished...