Coke

Coke

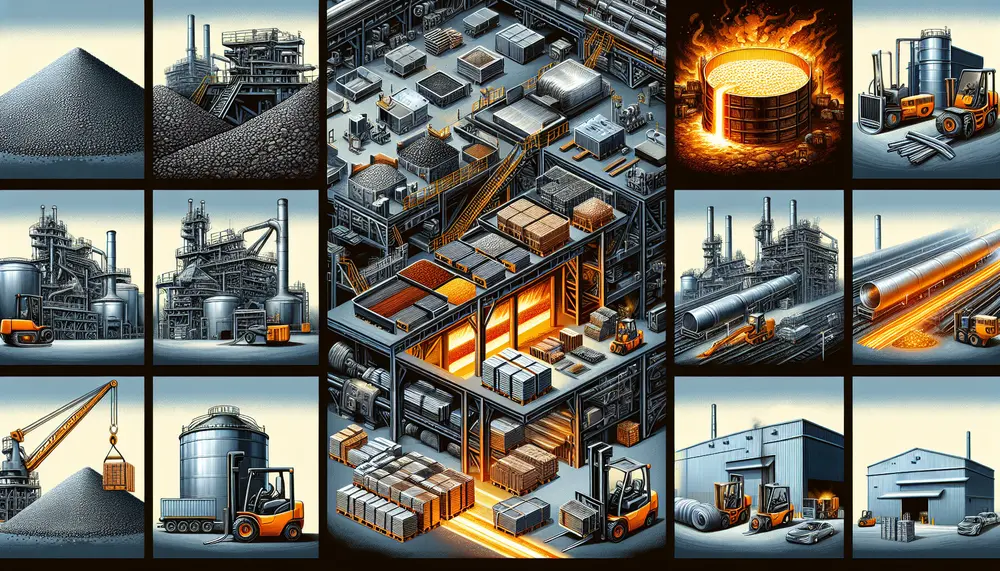

Coke ist ein wichtiger Begriff in der Welt der Stahlproduktion und des Stahlhandels. Als Brennstoff und Reduktionsmittel spielt er eine entscheidende Rolle im Prozess der Eisenherstellung.

Was ist Coke?

Der Begriff 'Coke' bezieht sich auf ein Produkt, das durch das Erhitzen von Kohle in einem Ofen ohne Sauerstoffzugang entsteht. Dieser Prozess nennt man Kokserzeugung. Der dabei entstehende Coke hat höhere energiebündelnde Eigenschaften und enthält weniger Verunreinigungen als die ursprüngliche Kohle.

Warum ist Coke wichtig in der Stahlproduktion?

Coke ist ein Schlüsselmaterial in der Stahlproduktion, weil er sowohl als Brennstoff als auch als Reduktionsmittel in Hochofenprozessen verwendet wird. Als Brennstoff erzeugt Coke die hohe Temperatur, die benötigt wird, um das Eisenerz zu schmelzen. Als Reduktionsmittel hilft Coke, die Sauerstoffatome aus dem Eisenerz zu entfernen und so reines Eisen zu produzieren.

Die Rolle von Coke im Stahlhandel

In der Stahlhandel Branche hängt die Nachfrage nach Coke direkt von der Stahlproduktion ab. In Ländern mit hohen Stahlproduktionsraten ist also auch die Nachfrage nach Coke hoch. Hohe Nachfrage bedeutet oft höhere Preise, und das kann den Wert von Coke auf dem Markt steigern.

Zusammenfassung

Zusammenfassend lässt sich sagen, dass Coke eine wesentliche Rolle in der Produktion und im Handel von Stahl spielt. Seine einzigartige Funktion als Brennstoff und Reduktionsmittel macht ihn unverzichtbar in der Stahlindustrie. Daher ist es wichtig, die Bedeutung und Verwendung von Coke zu verstehen, egal ob man in der Stahlproduktion oder im Stahlhandel tätig ist.

Blog Posts with the term: Coke

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

The article provides an overview of the two main steelmaking routes: blast furnace (BF) and electric arc furnace (EAF), detailing their processes, economic considerations, environmental impacts, and technological advancements. It compares BF's large-scale production with high carbon emissions to EAF's...

Coke is crucial in steel production, providing heat and chemical reactions for smelting iron ore while also structuring the blast furnace. However, its use emits pollutants and CO2, contributing to environmental concerns....

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

The article "Introduction to Steelmaking from Pig Iron" explores the historical and modern processes of transforming pig iron into steel, including methods like the Bessemer Process, Basic Oxygen Steelmaking (BOS), and Electric Arc Furnace (EAF). It highlights the importance of...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...

Steel's origins trace back to meteoric iron and evolved with human discovery of smelting around 2500 BCE, leading from the Bronze Age into the Iron Age. The Bessemer Process in the mid-19th century revolutionized steel production, enabling mass production and...

The steelmaking industry is increasingly using natural gas to improve efficiency and reduce environmental impact. Natural gas serves as a reducing agent in Direct Reduced Iron (DRI) processes, partially replaces coke in blast furnaces, fuels various types of industrial furnaces,...

Steel production is a highly energy-intensive process with significant environmental impacts, making the understanding and monitoring of energy consumption at each stage crucial for sustainability. Energy efficiency in steel manufacturing is essential for cost-effectiveness, competitiveness, and reducing carbon emissions, with...

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

Steel production, a complex process involving several stages from mining of raw materials to creation of the final product, significantly impacts the price and sustainability of steel. Understanding this value chain is crucial for decision-making in the industry as it...

Japan's steel industry rose from the post-WWII era to become a global leader through strategic investments in technology, quality control, and export-oriented policies. Key factors for this success include R&D commitment, high-quality standards, advantageous locations for trade routes, skilled workforce...