Defect

Defect

Willkommen in unserem Online-Magazin-Steel-Glossar! Heute werden wir uns mit dem Begriff Defekt in Bezug auf die Stahlproduktion und den Stahlhandel auseinandersetzen. Dieser Terminus wird oft missverstanden, daher ist es wichtig, eine klare Definition und Erklärung zu haben.

Definition von Defekt

Ein Defekt in der Stahlproduktion ist jede Art von Fehler oder Unregelmäßigkeit, die in einem Stahlprodukt auftritt. Es kann sich um eine physische Beschädigung, eine Abschwächung der Struktur oder eine Unregelmäßigkeit in der Farbe oder Textur handeln.

Häufige Defekte in der Stahlproduktion

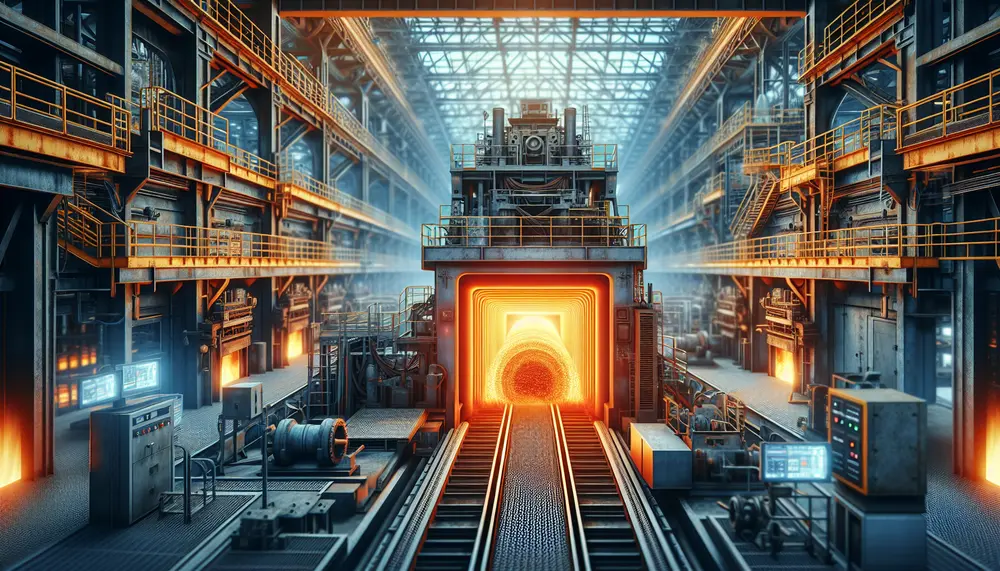

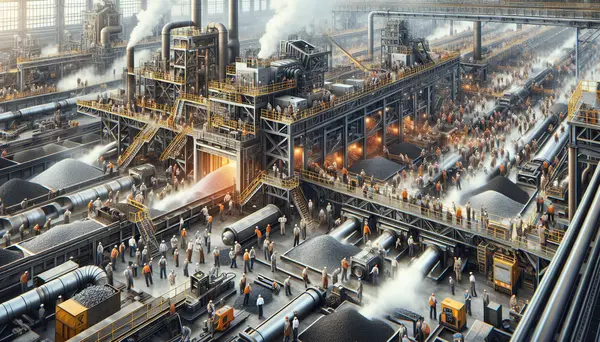

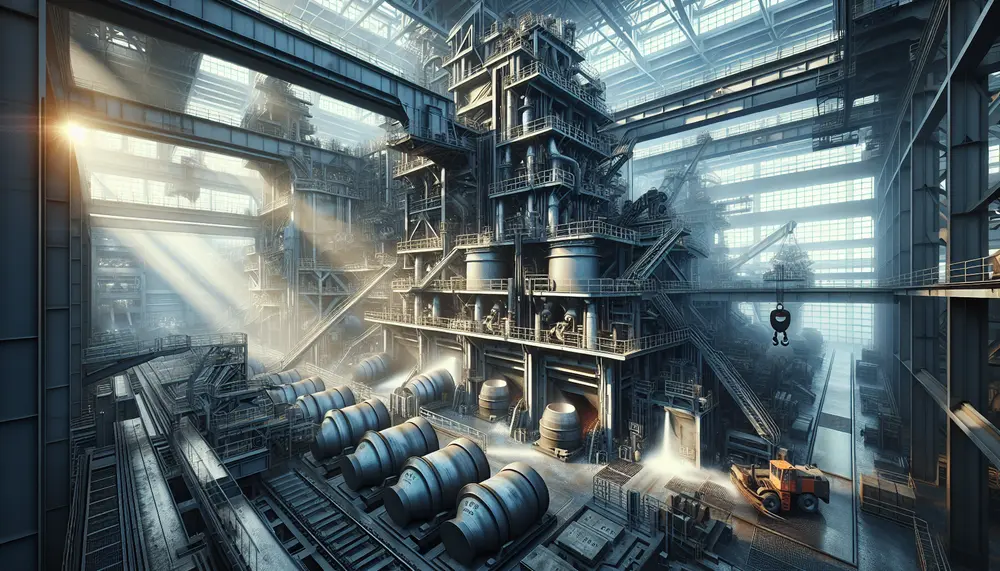

Defekte in der Stahlproduktion können aus vielen Gründen auftreten. Einige der am häufigsten auftretenden Defekte sind Unebenheiten in Form von Beulen oder Rissen, Diskrepanzen in den Abmessungen oder Gewicht, Rostbildung oder andere Formen der Korrosion, und Verfärbungen. Fehler im Produktionsprozess selbst können auch zu Defekten führen, wie beispielsweise fehlerhaftes Walzen oder unsachgemäße Wärmebehandlung.

Defekt-Management in der Stahlproduktion und im Stahlhandel

Das Management von Defekten ist ein wichtiger Teil der Stahlproduktion und des Stahlhandels. Stahlproduzenten setzen fortschrittliche Prüf- und Kontrollverfahren ein, um sicherzustellen, dass ihre Produkte die höchste Qualität aufweisen. Stahlhändler wiederum müssen sich darauf verlassen können, dass die Produkte, die sie erwerben, frei von Defekten sind. Beim Verkauf von Stahlprodukten spielt die genaue Beschreibung möglicher Defekte eine wichtige Rolle im Transparenz- und Vertrauensaufbau mit Kunden.

Schlussfolgerung

Letztlich sind Defekte keine Seltenheit in der Stahlproduktion, und ihre korrekte Identifizierung, Handhabung und Offenlegung ist entscheidend für den Erfolg sowohl der Produzenten als auch der Händler. Durch ständige Verbesserung der Produktionsprozesse und strengere Kontrollen wird angestrebt, die Anzahl der Defekte so gering wie möglich zu halten.

Blog Posts with the term: Defect

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

The manufacturing of steel balls is a complex process involving precise steps to produce high-quality products for various applications. It starts with selecting the right raw materials and includes forging, flashing, heat treating, grinding, lapping, and rigorous inspections to ensure...

Steel making involves complex chemical reactions to transform raw materials into high-quality steel, primarily through oxidation and reduction processes. Oxygen plays a crucial role in oxidizing impurities like carbon, silicon, manganese, and phosphorus, which are then removed as gases or...

The article provides an overview of steel making, detailing its historical evolution and main processes such as ironmaking, primary and secondary steelmaking, casting, and forming; it highlights the importance of methods like the basic oxygen process and electric arc furnace...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

Induction furnaces have transformed steel making with their efficiency, versatility, and reduced environmental impact compared to traditional fossil fuel-based furnaces. They use electromagnetic induction for heating metals precisely and quickly, offering benefits like energy savings, improved productivity, metallurgical control, scalability,...

The iron and steel industry is undergoing a new era of innovation, driven by advancements in automation, energy efficiency, and carbon reduction. Key trends include the use of AI and IoT for fully automated plants, advanced production technologies that require...

Steelmaking ladles are essential in the steel production process, designed to transport and refine molten metal while withstanding extreme temperatures and chemical corrosion. They come in various types tailored for specific functions such as transferring, treating, casting, and precise pouring...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...

Desulfurization in steelmaking is crucial for producing high-quality, durable steel by removing sulfur impurities that cause brittleness; advancements and techniques like desulfurizing agents, slag optimization, and vacuum treatment enhance this process while addressing challenges such as cost and environmental concerns....

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

The Electric Arc Furnace (EAF) is revolutionizing steelmaking by using electricity to melt scrap metal, reducing carbon emissions and supporting recycling efforts in a circular economy....

Steelmaking rolling is a crucial process that transforms raw steel into various usable forms by passing it through rollers to reduce thickness, improve uniformity, and achieve specific mechanical properties. The article details the stages of hot and cold rolling, the...

JSW Steel employs advanced technology and sustainable practices in its steel manufacturing process, starting with the selection of raw materials like iron ore and coal. The company focuses on producing high-quality steel through a series of steps including melting, refining,...