Etching

Etching

Definition of Etching

The term "Etching" refers to an artful, yet industrial process used widely in the sector of steel production and steel trade. Etching leaves a beautiful impression on the steel surface.

Etching: The Process Simplified

In a nutshell, Etching involves using a chemical substance also referred to as an etchant or mordant. This element reacts with the material's surface, in our case steel, to create an intended design or pattern.

Etching in Steel Production

In the context of steel production, etching takes place before or after the steel takes its final form. In some cases, etching becomes necessary for inspection and analysis of the steel. For instance, it helps in identifying any hidden cracks or defects, otherwise difficult to detect on the raw steel surface.

The Importance of Etching in Steel Trade

In the world of steel trade, aesthetics matter. Etching helps make steel more than just a durable product. It turns steel into appealing designs that many sectors appreciate across the board. From construction to interior design, etched steel products are highly sought after for their unique looks.

Final Words on Etching

In conclusion, Etching is a technique with both functional and aesthetic benefits in the steel production and steel trade sector. It helps detect any defects early, thus ensuring quality. More so, it transforms steel into a work of art, adding value to the final product.

Blog Posts with the term: Etching

The steel industry is essential but poses significant risks to workers, including physical dangers from heavy machinery and extreme heat, chemical hazards from toxic substances, burn threats due to high temperatures in furnaces, and noise pollution leading to potential hearing...

The steel industry in the Netherlands is integral to its economy, known for innovation and sustainability, with a focus on high-grade production used across various sectors. The Dutch sector's evolution has been shaped by historical shifts and strategic investments like...

The article provides an in-depth look at the metal production process, from mining and refining ores to primary forming and secondary processes like heating, forming, cooling. It also explores different types of metal production methods including forging, casting, drawing/forming/machining, extrusion/cutting,...

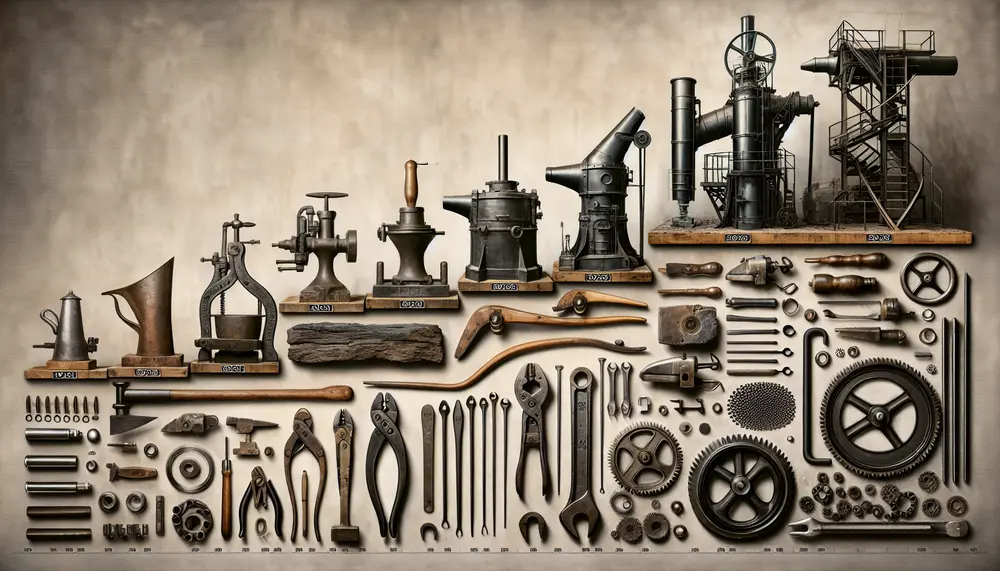

Steelmaking has evolved from early iron manipulation to advanced processes like the Bessemer method, which revolutionized mass steel production and infrastructure development. Technological advancements such as open hearth furnaces and electric arc furnaces further refined steel's properties, while British dominance...

Steel tube manufacturing is essential for industries like construction, energy, and transportation, offering seamless tubes for strength and welded ones for cost-efficiency. The processes involve precise engineering to ensure durability, versatility, and performance tailored to specific applications....

Steel is a versatile and crucial industrial material made from iron, carbon, and other elements; its production involves processes like primary steelmaking (BOF and EAF) and secondary refining to achieve desired properties for various applications....

Modern Damascus steel combines layered, contrasting steels and precise forging to create blades that are both visually striking and technically superior. Success relies on careful material selection, temperature control, pattern engineering, safety measures, and attention to detail at every step....

Viking steel, especially in Ulfberht swords, showcased advanced metallurgy with high purity and strength centuries ahead of its time, achieved through secretive techniques still not fully understood....

Wootz steel, originating in ancient southern India, was renowned for its unique microstructure and exceptional performance, fueling centuries of global trade and legend....

The article explores the historical and cultural significance of steel making, detailing ancient techniques like crucible steel production and emphasizing the importance of mastering carbon interaction in crafting high-quality steel....

The steel manufacturing process involves three main steps: production of molten iron from raw materials, purification and conversion to steel, and casting into shapes for finished products. This energy-intensive process has evolved due to environmental concerns and the demand for...