Galvanizing

Galvanizing

Einführung ins Galvanizing

In der Stahlproduktion und im Stahlhandel ist der Begriff Galvanizing, oder auf Deutsch 'verzinken', von besonderer Bedeutung. Doch was bedeutet es tatsächlich? Einfach ausgedrückt, Galvanizing ist ein Prozess, bei dem Stahl oder Eisen in geschmolzenes Zink getaucht wird. Die Absicht dieses Prozesses ist es, die Oberfläche des Metalls mit einer Schutzschicht zu überziehen, um Korrosion zu verhindern.

Der Galvanizing Prozess

Im Galvanizing-Prozess werden Stahlteile zuerst von jeglicher Oberflächenverschmutzung gereinigt. Dies wird normalerweise durch ein Bad in einer alkalischen Reinigungslösung oder durch Beizen in einer Säurelösung erreicht. Anschließend werden die Teile in einen Kessel mit flüssigem Zink von etwa 450 Grad Celsius getaucht. Wenn der Stahl mit dem heißen Zink in Kontakt kommt, reagiert er, um eine Reihe von Zink-Eisen-Legierungen zu bilden. Diese Legierungsschichten bilden die Galvanisierung, die eine effektive Barriere gegen Rostbildung bietet.

Nachhaltigkeit des Galvanizing

Eine der Schlüsseleigenschaften, die Galvanizing in der modernen Stahlproduktion und -handel attraktiv macht, ist seine Nachhaltigkeit. Ein galvanisiertes Produkt hat eine lange Lebensdauer und erfordert minimalen Wartungsaufwand. Dadurch trägt Galvanizing dazu bei, die Umweltauswirkungen der Stahlproduktion zu minimieren, indem es die Notwendigkeit für häufige Ersatz- und Reparaturarbeiten reduziert.

Abschließende Gedanken zu Galvanizing

Zusammenfassend lässt sich sagen, dass Galvanizing ein wichtiger Prozess in der Welt der Stahlproduktion und des Stahlhandels ist. Es bietet eine effektive Schutzschicht gegen Rost und korrosive Elemente, erhöht die Lebensdauer von Stahlprodukten und fördert die Nachhaltigkeit. So spielt Galvanizing eine schlüsselrolle in unserem täglichen Leben, indem es die Gebäude, Brücken und Autos, die uns umgeben und die wir benutzen, sicher und haltbar macht.

Blog Posts with the term: Galvanizing

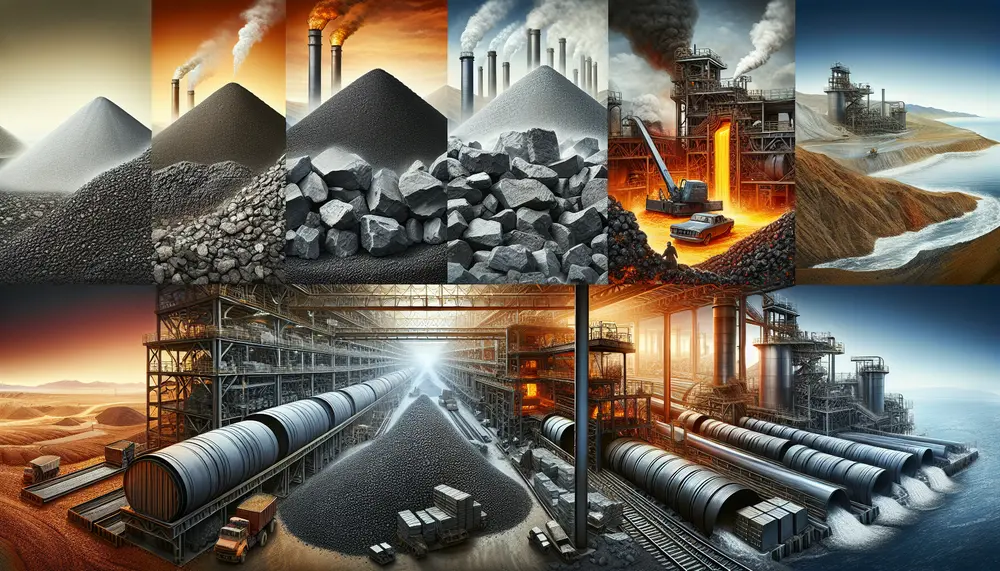

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

Steel manufacturing from scrap is a sustainable process that reduces environmental impact and conserves resources. It involves collection, separation, melting in an electric arc furnace, refining to remove impurities, adding alloy elements, and casting into new products; recycling steel offers...

JSW Steel employs advanced technology and sustainable practices in its steel manufacturing process, starting with the selection of raw materials like iron ore and coal. The company focuses on producing high-quality steel through a series of steps including melting, refining,...

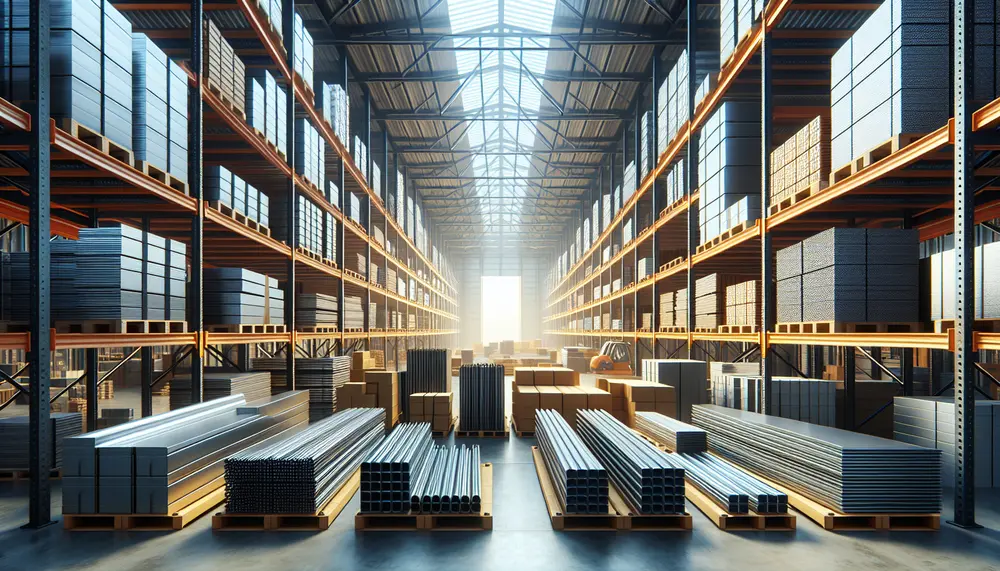

A steel product is an item predominantly made of steel, known for its durability and versatility across industries, with a wide range of forms and applications. Understanding these products involves knowledge of the production process from raw materials to finished...

The article explains the essential materials and processes involved in steel production, highlighting iron ore, carbon (coke), limestone, manganese, aluminum, and zinc as key components. It details how these elements are processed through smelting and alloying to enhance properties like...

The steel making process at SAIL involves meticulous selection of raw materials and advanced technology in blast furnaces to produce molten iron, which is then refined using BOF or EAF methods. Rigorous quality control ensures the final product meets international...

Steel making is a complex process involving the production of steel from iron ore and scrap, where impurities are removed and alloying elements added to create different grades. The process includes two main steps: ironmaking (extracting iron from ore) and...

Steel production is a complex process combining traditional methods and modern technology to transform raw materials into versatile, durable products essential for industries like construction, automotive, energy, and consumer goods. Its adaptability ensures steel remains vital in innovation and sustainable...

Modern steel factories combine advanced technology, automation, and strict quality control to transform raw materials into high-quality steel with precision and efficiency....