Grain Structure

Grain Structure

Was ist die "Grain Structure"?

Der Begriff "Grain Structure" bezieht sich auf die Anordnung und Größe der Kristallkörner in einer Materialprobe, in unserem Fall speziell der Stahlproduktion und dem Stahlhandel. Diese Struktur ist ein wichtiger Faktor, der die mechanischen Eigenschaften von Metallen beeinflusst.

Warum ist die "Grain Structure" wichtig?

Die "Grain Structure" kann die Härte, Zähigkeit und andere wichtige Eigenschaften von Stahl stark beeinflussen. Grobe Körner können zum Beispiel zu einer Erhöhung der Zähigkeit führen, aber auch zu einer Verringerung der Härte und Festigkeit. Feine Körner hingegen können die Härte und Festigkeit des Stahls erhöhen, allerdings auf Kosten der Zähigkeit.

Wie wird die "Grain Structure" manipuliert?

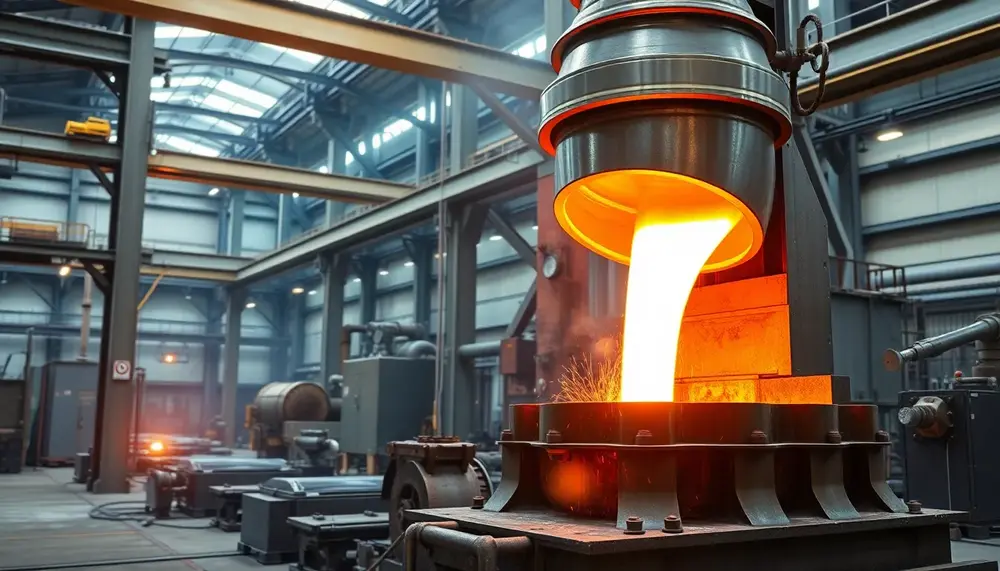

Die "Grain Structure" wird oft durch Wärmebehandlungsprozesse manipuliert. Durch das Erhitzen und anschließende kontrollierte Abkühlen von Stahl kann ein Metallurge die Größe der Körner im Stahl verändern. Dieser Prozess wird als Kornveredelung oder Korngrößenkontrolle bezeichnet.

Welche Auswirkung hat die "Grain Structure" auf den Stahlhandel?

Im Stahlhandel ist die Kenntnis der "Grain Structure" wichtig, um die Qualität und Verwendungsmöglichkeiten eines Stahlprodukts zu beurteilen. Unterschiedliche Anwendungen erfordern unterschiedliche Kornstrukturen. Ein Stahlprodukt mit feinem Korn kann beispielsweise in Anwendungen eingesetzt werden, bei denen hohe Festigkeit erforderlich ist. Ein Stahlprodukt mit grobem Korn hingegen ist oft besser für Anwendungen geeignet, bei denen eine hohe Zähigkeit wichtiger ist.

Blog Posts with the term: Grain Structure

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

Steel production is a complex process combining traditional methods and modern technology to transform raw materials into versatile, durable products essential for industries like construction, automotive, energy, and consumer goods. Its adaptability ensures steel remains vital in innovation and sustainable...

Modern Damascus steel combines layered, contrasting steels and precise forging to create blades that are both visually striking and technically superior. Success relies on careful material selection, temperature control, pattern engineering, safety measures, and attention to detail at every step....

The concept of steelmaking grade is crucial in determining the quality and properties of steel, influencing efficiency, durability, and safety across various industries. Steel grades are classified based on chemical composition and production processes, with advancements in technology and global...

Steel refining transforms raw materials into high-quality steel by removing impurities and enhancing properties through advanced techniques like BOF, EAF, and DRI. Modern innovations ensure precision, efficiency, sustainability, and tailored applications across industries while addressing environmental challenges....

The article provides an in-depth look at the steelmaking process, covering its history from ancient methods to modern techniques like the Bessemer and Siemens-Martin processes. It details key stages such as raw material preparation, primary and secondary steelmaking, casting, shaping,...

Steel making hammers are essential tools designed for durability, precision, and efficiency in metalworking processes, with various types tailored to specific tasks. Choosing the right hammer type and material ensures enhanced productivity, longevity, and craftsmanship quality in steel forging applications....

Vacuum Induction Melting (VIM) revolutionizes steel-making by enabling ultra-pure alloys through precise melting, impurity removal in a vacuum, and real-time composition control. Recent innovations like advanced monitoring systems, hybrid techniques, and energy-efficient designs enhance material quality while promoting sustainability for...

Steel production is a complex process that transforms raw materials like iron ore, limestone, and coke into steel through stages such as iron making in blast furnaces, primary and secondary steelmaking for purification and customization, casting to form solid shapes,...

Viking steel, especially in Ulfberht swords, showcased advanced metallurgy with high purity and strength centuries ahead of its time, achieved through secretive techniques still not fully understood....

A well-structured PowerPoint on stainless steel manufacturing uses clear visuals and icons to simplify complex processes, enhance understanding, and support actionable insights....

Quenching is a key process in steel production that rapidly cools metal to change its microstructure, increasing hardness and strength by creating martensitic structure. The choice of cooling medium—water, oil, air or others—affects the rate of cooling and final properties...

Steel's origins trace back to the use of iron by ancient civilizations and its transformation through smelting, leading to steel production once carbon content control was mastered. The evolution of steelmaking techniques has progressed from labor-intensive methods like the crucible...