Heat treatment

Heat treatment

Was ist Heat Treatment?

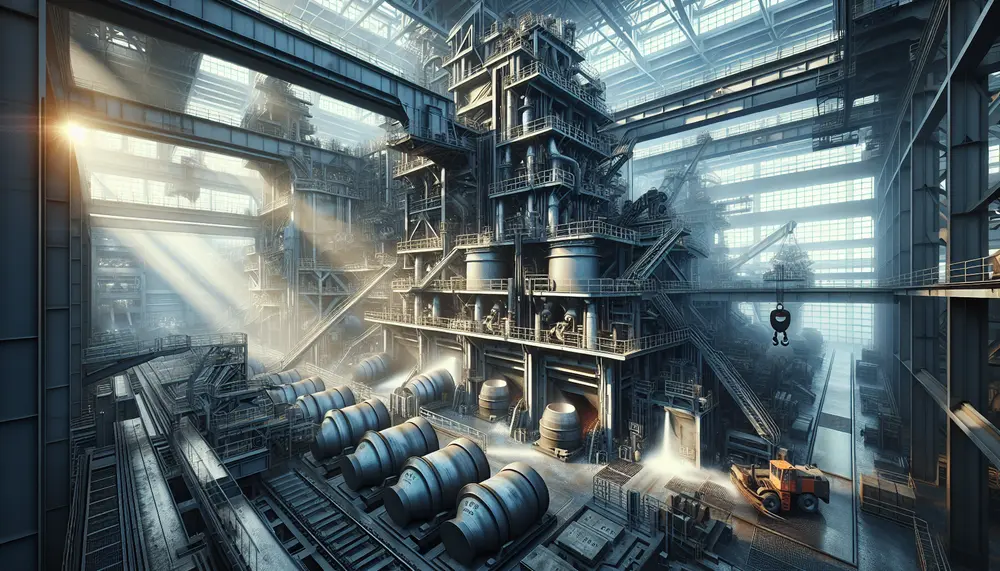

Mit Blick auf die Steel production and steel trade kommt ein Begriff immer wieder zur Sprache: Heat treatment. Aber was bedeutet das eigentlich? Vereinfacht gesagt, ist die Heat treatment ein Verfahren, bei dem Stahl erhitzt und anschließend abgekühlt wird. Das alles geschieht in vorher festgelegten Zeit- und Temperaturverläufen. Dabei werden dem Stahl gewünschte Eigenschaften verliehen, die seine spätere Verwendung bestimmen.

Warum ist Heat treatment wichtig?

Die Heat treatment beeinflusst maßgeblich die Struktur und somit auch die Eigenschaften von Stahl. Die mechanischen Eigenschaften wie Härte, Zugfestigkeit und Zähigkeit des Stahls können durch die Wärmebehandlung optimiert werden. Das ermöglicht, Stahl an die jeweiligen Anforderungen anzupassen und somit seine Verwendungsmöglichkeiten zu erweitern.

Welche Arten von Heat treatment gibt es?

Es gibt unterschiedliche Verfahren der Heat treatment. Eine der bekanntesten Methoden ist das Härten. Dabei wird der Stahl auf eine hohe Temperatur erhitzt und schnell abgekühlt, um die Härte zu steigern. Eine andere Methode ist das Anlassen. Hier wird der zuvor gehärtete Stahl erneut erhitzt und langsam abgekühlt. Das macht ihn widerstandsfähiger gegenüber ruckartigen Belastungen.

Heat treatment in der Steel production and steel trade

In der Steel production and steel trade spielt die Heat treatment eine zentrale Rolle. Am Ende entscheidet sie über die Qualität des Endproduktes. So ist die Heat treatment immer ein bedeutender Schritt entfernt von der Herstellung von Bauteilen wie Zahnrädern oder Werkzeugstahl. Aber auch bei der Produktion von Edelstahl und anderen Stahlsorten ist sie unerlässlich.

Blog Posts with the term: Heat treatment

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The steelmaking industry is increasingly using natural gas to improve efficiency and reduce environmental impact. Natural gas serves as a reducing agent in Direct Reduced Iron (DRI) processes, partially replaces coke in blast furnaces, fuels various types of industrial furnaces,...

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...

Steel was crucial in World War II, serving as the backbone for military equipment and influencing nations' industrial might. The escalation of steel production played a pivotal role in the Allied victory, with advancements in technology and massive job creation. Steel's...

The manufacturing of steel balls is a complex process involving precise steps to produce high-quality products for various applications. It starts with selecting the right raw materials and includes forging, flashing, heat treating, grinding, lapping, and rigorous inspections to ensure...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

The article "Introduction to Ancient Steel Making" explores the historical context, key techniques, and materials used in ancient steel production across various civilizations. It highlights how early methods influenced modern steel making and underscores the ingenuity of our ancestors in...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

Steel production relies on a balance of raw materials like iron ore, coal, limestone, and scrap metal to determine the characteristics of different steel types. Understanding these ingredients is crucial for industry professionals as they influence strength, durability, and quality...