Hot metal

Hot metal

Was ist Hot Metal?

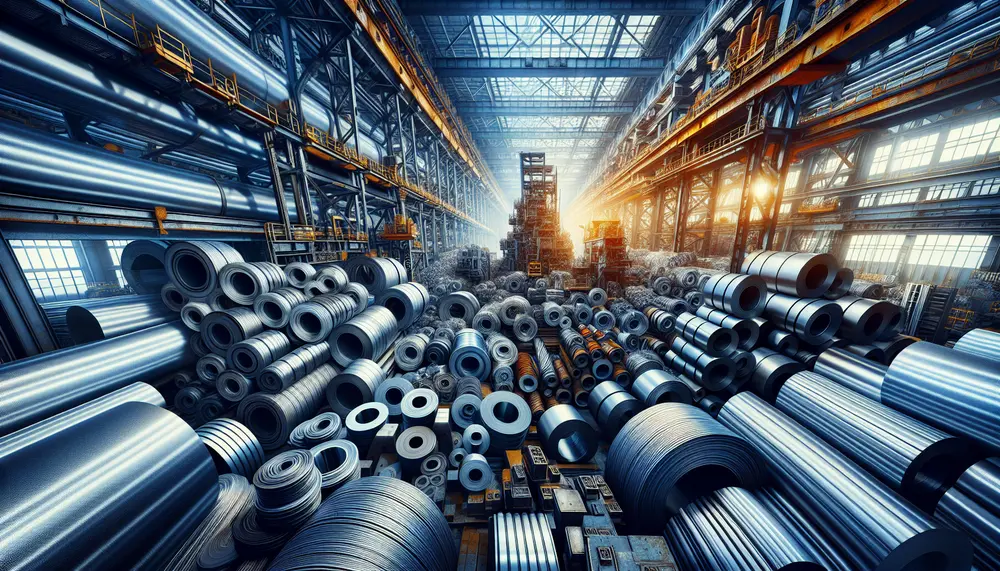

Hot Metal ist ein igoristischer Begriff, der oft in der Stahlproduktion und dem Stahlhandel verwendet wird. Es bezieht sich auf Roheisen, das durch einen Prozess namens Hochtemperatur-Reduktion aus Eisenerzen gewonnen wird. Dieses heiße, flüssige Eisen, auch als 'Hot Metal' bezeichnet, ist der Brennpunkt in der Stahlherstellung.

Wie kommt Hot Metal zustande?

Hot Metal entsteht durch Erhitzung von Eisenerzen in einem Hochofen. Bei etwa 1.600 Grad Celsius reagiert das Eisenoxid in den Erzen mit Kohlenmonoxid, das durch Verbrennung von Kohle erzeugt wird. Dies führt zur Entstehung von flüssigem Eisen, das dann durch den Ausfluss am Boden des Hochofens abgelassen wird, wo es als 'Hot Metal' bezeichnet wird.

Die Rolle von Hot Metal in der Stahlherstellung

Das flüssige Eisen, nun als Hot Metal bekannt, ist das Ausgangsmaterial für die Stahlherstellung. Es wird in den Konverter geleitet, wo es weiter behandelt wird, um Stahl herzustellen. Durch Hinzufügen von Sauerstoff werden die restlichen Verunreinigungen aus dem Hot Metal entfernt und eine legierte Form von Stahl hergestellt. Dieser Prozess erhöht den Kohlenstoffgehalt und verbessert die Qualität des Stahls merklich.

Hot Metal in der Stahlindustrie

In der Stahlindustrie ist Hot Metal ein wichtiger Faktor. Seine Qualität spielt eine entscheidende Rolle für die finale Qualität des erzeugten Stahls. Darum legen Hersteller großen Wert auf die Überwachung der Temperatur und Zusammensetzung des Hot Metals, um eventuelle Verunreinigungen zu minimieren und somit die Qualität des Endprodukts zu gewährleisten.

Zusammenfassung

Um es zusammenzufassen, Hot Metal ist ein integraler Bestandteil der Stahlproduktion und -handel. Es ist das flüssige Roheisen, das durch die Reduktion von Eisenerz in einem Hochofen erzeugt wird und zur weiteren Verarbeitung in der Stahlherstellung dient. Durch seine zentrale Rolle in diesem Prozess ist es ein maßgeblicher Faktor für die Qualität des resultierenden Stahls.

Blog Posts with the term: Hot metal

The steel industry is essential but poses significant risks to workers, including physical dangers from heavy machinery and extreme heat, chemical hazards from toxic substances, burn threats due to high temperatures in furnaces, and noise pollution leading to potential hearing...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The steelmaking industry is increasingly using natural gas to improve efficiency and reduce environmental impact. Natural gas serves as a reducing agent in Direct Reduced Iron (DRI) processes, partially replaces coke in blast furnaces, fuels various types of industrial furnaces,...

The global steel production landscape is a complex network essential for various industries, influenced by factors like raw material availability and technological advancements. China leads in output with other key players being India, Japan, and the US; sustainability efforts are...

The blast furnace steel making process involves transforming raw materials into molten iron, which is then processed to produce steel. Key components include coke, iron ore and limestone; the former provides heat while the latter two undergo chemical reactions in...

The steel making process, which starts with the extraction of iron ore and involves several steps to create different types of steel, is transitioning towards more sustainable methods like the Basic Oxygen Furnace (BOF) method. The BOF method turns raw...

The Basic Oxygen Furnace (BOF) process, developed in the mid-20th century by Robert Durrer, revolutionized steel production by using pure oxygen to convert molten iron into high-quality steel efficiently. This method involves charging a furnace with molten iron and scrap...

ArcelorMittal's steel making process combines traditional methods with advanced technologies, focusing on sustainability and efficiency. The company continuously innovates to improve quality and reduce environmental impact while maintaining a strategic approach to resource management in the global steel industry....

Steelmaking is vital to modern civilization, driving economies, infrastructure development, and sustainability efforts. The industry relies on two main methods—Blast Furnace (BF) for large-scale production with higher emissions and Electric Arc Furnace (EAF) for flexibility and lower environmental impact—shaping a...

The steel making process at SAIL involves meticulous selection of raw materials and advanced technology in blast furnaces to produce molten iron, which is then refined using BOF or EAF methods. Rigorous quality control ensures the final product meets international...

The steel making process transforms iron ore into a vital and robust material through complex technical procedures, reflecting human ingenuity and progress. This journey from extraction to the final product involves meticulous steps including smelting in blast furnaces, oxidation for...

Steel is a versatile material essential to modern industry, with various grades tailored for specific uses from construction to technology. Its key advantages include durability, resistance to extreme conditions, and recyclability, making it integral in innovation and sustainability efforts across...

Steelmaking transforms iron into steel by increasing carbon content and refining the material through methods like blast furnaces and adding additives. Modern techniques include Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), focusing on sustainability, with raw materials such...