Hot rolling

Hot rolling

Einführung in das Hot Rolling

Wenn Sie sich mit der Stahlproduktion und dem Stahlhandel beschäftigen, stoßen Sie mit Sicherheit auf Hot Rolling. Aber was genau bedeutet das? Einfach ausgedrückt, ist Hot Rolling ein Prozess, der das Formen von Stahl bei hohen Temperaturen ermöglicht.

Der Prozess des Hot Rollings

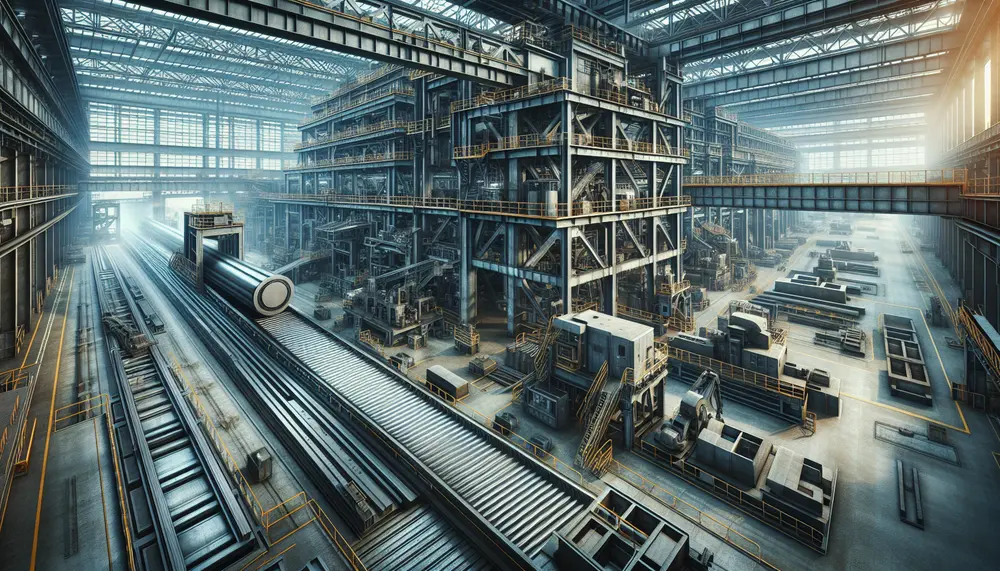

Hot Rolling ist ein Verfahren, bei dem Stahl oder anderes Metall bei Temperaturen erhitzt wird, die über dem Rekristallisationstempunkt des Metalls liegen. Bei solch hohen Temperaturen wird das Metall weicher und lässt sich leichter formen. Daher ist Hot Rolling ein wichtiger Prozess in der Stahlindustrie, um verschiedenste spezielle Formen und Größen herzustellen.

Nutzen von Hot Rolling

Der Hauptvorteil von Hot Rolling besteht darin, dass dieses Verfahren die Produktion von größeren Mengen Stahl ermöglicht. Da das Metall in einem weichen Zustand bearbeitet wird, ist es möglich, eine größere Menge in kürzerer Zeit zu produzieren. Zusätzlich verbessert Hot Rolling auch die mechanischen Eigenschaften des Stahls, was zu einem widerstandsfähigeren Produkt führt.

Arten von Produkten durch Hot Rolling

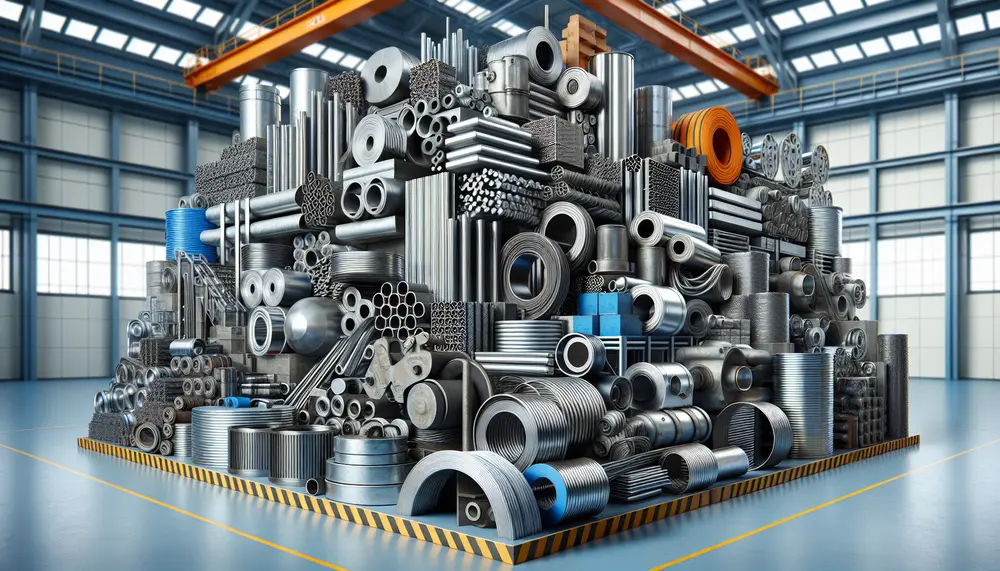

Mit dem Hot Rolling Verfahren lassen sich eine Vielzahl von Produkten herstellen, die in verschiedenen Branchen zum Einsatz kommen. Dazu gehören Flachstähle, Stahlbleche, Röhren, Profile und Stangen. Diese Produkte sind in Branchen wie dem Bauwesen, der Automobilindustrie und dem Maschinenbau unverzichtbar.

Zusammenfassung

Im Kontext von Stahlproduktion und Stahlhandel ist Hot Rolling ein äußerst wichtiger Prozess. Durch das Erhitzen und anschließende Formen des Stahls entstehen viele verschiedene Produkte, die in verschiedensten Branchen Anwendung finden. Darüber hinaus ermöglicht Hot Rolling die Produktion von hochwertigem Stahl in großen Mengen.

Blog Posts with the term: Hot rolling

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

The article provides an in-depth look at the role of steel products across various industries, highlighting their diverse applications and importance. It covers the basics of steel production, compares uses in different sectors, explains differences between hot-rolled and cold-rolled steel,...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

Steelmaking rolling is a crucial process that transforms raw steel into various usable forms by passing it through rollers to reduce thickness, improve uniformity, and achieve specific mechanical properties. The article details the stages of hot and cold rolling, the...

JSW Steel employs advanced technology and sustainable practices in its steel manufacturing process, starting with the selection of raw materials like iron ore and coal. The company focuses on producing high-quality steel through a series of steps including melting, refining,...

Steel manufacturing from scrap is a sustainable process that reduces environmental impact and conserves resources. It involves collection, separation, melting in an electric arc furnace, refining to remove impurities, adding alloy elements, and casting into new products; recycling steel offers...

A steel product is an item predominantly made of steel, known for its durability and versatility across industries, with a wide range of forms and applications. Understanding these products involves knowledge of the production process from raw materials to finished...

Steel making machines have revolutionized the industry by increasing production speed, improving quality, and enabling precise designs through automation and advanced technology. Automation in steel production has evolved from manual processes to sophisticated machinery that enhances efficiency, safety, and sustainability...

Steel manufacturing is a complex, multi-stage process that transforms raw materials into the durable metal essential for modern infrastructure. It begins with extracting iron ore and progresses through various phases including blast furnace operation and primary steelmaking methods like Basic...