Inclusions

Inclusions

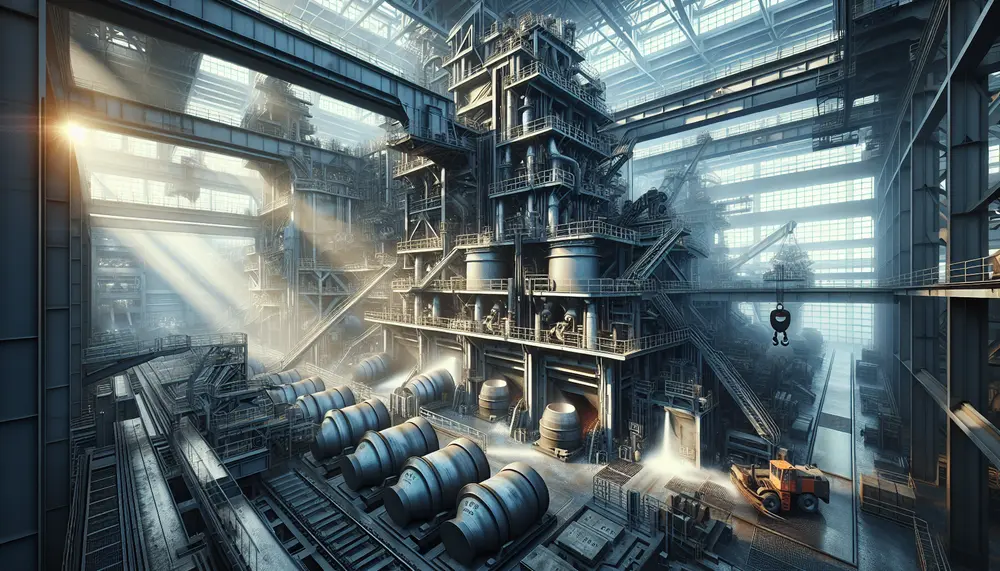

Inclusions sind ein wichtiges Thema in der Stahlproduktion und im Stahlhandel. Doch was genau sind Inclusions? Mit einfachen Worten, Inclusions sind winzige feste Fremdkörper, die in flüssigem Stahl enthalten sind. Sie stammen oft von Unreinheiten im ursprünglichen Roheisen oder von Verunreinigungen, die während des Prozesses eingeführt werden. Diese Inclusions können die Qualität und Eigenschaften des schließlich produzierten Stahls stark beeinflussen.

Typen von Inclusions

Es gibt mehrere Arten von Inclusions. Dazu gehören Oxide, Sulfide, Silikate und Nitride. Jeder Typ hat unterschiedliche Auswirkungen auf den Stahl. Einige können seine Festigkeit erhöhen, während andere seine Haltbarkeit mindern.

Auswirkungen von Inclusions

Starke Inclusions können das Schweißen und Formen von Stahl erschweren. Sie können auch die Festigkeit des Stahls mindern und Risse verursachen, wodurch die Struktur schwächer wird. Es ist daher wichtig, Inclusions zu minimieren um die Qualität des Stahls sicherzustellen.

Behandlung von Inclusions

Es gibt verschiedene Verfahren zur Beseitigung von Inclusions in der Stahlproduktion. Dazu gehören die Flotation, bei der Luftblasen durch den flüssigen Stahl geleitet werden, um Inclusions an die Oberfläche zu bringen, und die Vakuumbehandlung, bei der der Druck verringert wird, um Inclusions zu entfernen. Aber die Kontrolle und Behandlung von Inclusions ist ein fortlaufender Forschungsprozess in der Stahlindustrie.

Inclusions und Stahlqualität

Die Beziehung zwischen Inclusions und Stahlqualität ist komplex. In der Regel gilt: Je weniger und kleiner die Inclusions, desto besser die Qualität des Stahls. Allerdings kann in bestimmten Fällen eine gezielte Zugabe von Inclusions erwünscht sein, um spezielle Stahleigenschaften zu erzeugen.

Abschließend ist zu sagen, dass Inclusions ein wichtiger Aspekt in der Stahlproduktion und -handel sind. Ihre Behandlung und Kontrolle ist entscheidend für die Produktion von hochwertigem Stahl.

Blog Posts with the term: Inclusions

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

The article provides an overview of steel making, detailing its historical evolution and main processes such as ironmaking, primary and secondary steelmaking, casting, and forming; it highlights the importance of methods like the basic oxygen process and electric arc furnace...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...

Steelmaking flux is crucial in producing high-quality steel, acting as a cleansing agent to remove impurities and enhance the metal's properties. Different types of fluxes are used for specific tasks during production, impacting impurity removal and refining processes while protecting...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

Steelmaking oxidation is a critical process in steel production, involving the intentional addition of oxygen to molten iron to trigger chemical reactions that remove impurities like carbon, silicon, and phosphorus, thereby enhancing the quality and properties of steel. This process...

Steel manufacturing from scrap is a sustainable process that reduces environmental impact and conserves resources. It involves collection, separation, melting in an electric arc furnace, refining to remove impurities, adding alloy elements, and casting into new products; recycling steel offers...

The steel making LF process, involving a ladle furnace to refine molten steel, is essential for ensuring high-quality and specialized steel grades by controlling temperature and composition. Introduced in the 1960s, advancements in ladle furnaces have optimized this process, enhancing...

RH technology, initially developed for hydrogen removal in steel making, now plays a crucial role in secondary refining and purification to ensure high-quality steel production. Key advancements like oxygen lances, powder injection systems, the RH-TOP system, and modern vacuum pumps...

Secondary steelmaking refines and adjusts the composition of steel to meet specific standards, involving processes like deoxidation, desulfurization, decarburization, alloying, and degassing. It is crucial for producing high-quality steel with desired properties such as strength and corrosion resistance. The role of...

Steel fabrication involves transforming raw steel into structures or products using various techniques like cutting, bending, and joining to ensure strength and quality. Material selection is critical in this process as it affects the performance and longevity of the final...

The Ladle Metallurgy Furnace (LMF) is a crucial advancement in modern steel production, allowing for precise control over the chemical composition and temperature of molten steel to produce high-quality products. This technology involves transferring liquid steel into a specialized furnace...

Stainless steel making is a complex process that begins with melting iron ore and other elements like chromium and nickel to create a durable, corrosion-resistant material. This involves several stages including refining, casting, and rolling, controlled by precise temperature and...