Ingot casting

Ingot casting

Definition von Ingot Casting

Beim Ingot Casting, zu Deutsch 'Barrenguss', handelt es sich um einen wichtigen Prozess in der Stahlproduktion und dem Stahlhandel. Es bezeichnet das Gießen von flüssigem Stahl in Formen, die 'Ingot Moulds' genannt werden. Diese Formen sind in der Regel aus speziellem, hitzebeständigem Material gefertigt, das in der Lage ist, die hohen Temperaturen des flüssigen Stahls zu widerstehen.

Der Prozess des Ingot Casting

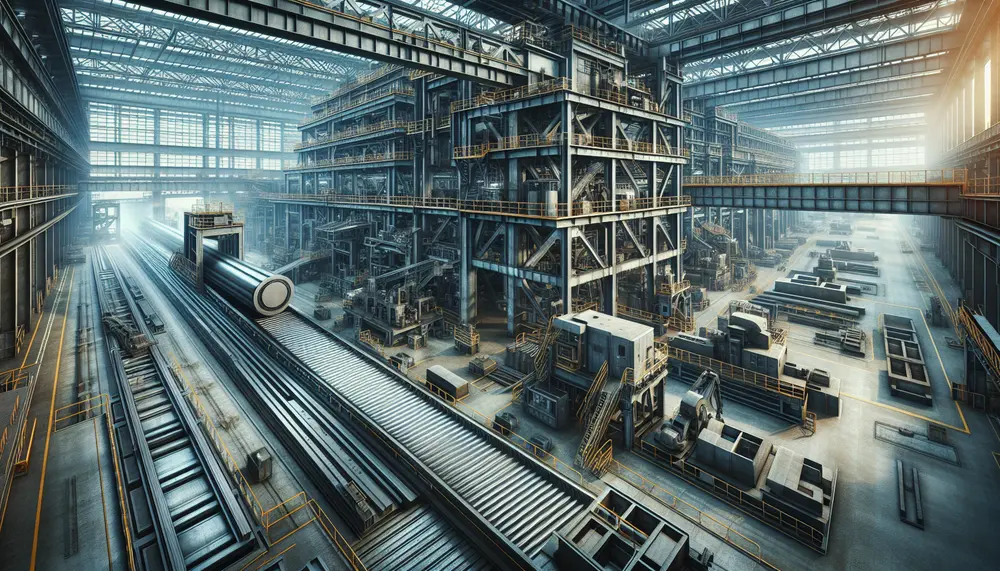

Im ersten Schritt wird der Stahl erhitzt, bis er schmilzt. Dies findet üblicherweise in einem Ofen statt. Der nun flüssige Stahl wird dann in die vorgesehenen Formen gegossen. Sobald der Stahl in den Formen abkühlt und sich verfestigt, bildet er die sogenannten Ingots. Diese werden aus den Formen entfernt und sind nun bereit für den weiteren Verarbeitungsprozess, wie zum Beispiel das Walzen.

Die Rolle von Ingot Casting in der Stahlproduktion und in Stahlhandel

In der Stahlindustrie ist das Ingot Casting von großer Bedeutung, da die so produzierten Ingots die Grundlage für die meisten weiteren Stahlprodukte bilden. Sie werden in weitere Prozesse wie Walzen, Schmieden oder Pressen eingebracht, um Stahlprodukte unterschiedlicher Formen und Größen zu erzeugen. Darüber hinaus spielen Ingots auch im Stahlhandel eine wichtige Rolle, da sie als eine Art 'Rohstoff' gehandelt werden können.

Nutzen und Vorteile des Ingot Casting

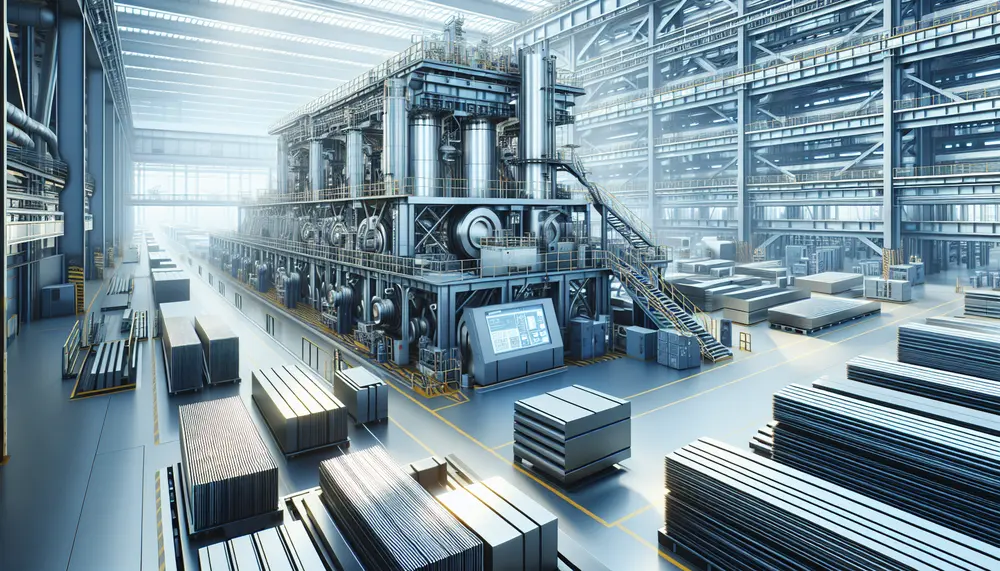

Das Ingot Casting bietet eine effiziente Methode, um flüssigen Stahl in eine handhabbare Form zu bringen. Es ermöglicht eine einfache Lagerung und den Transport von Stahl. Darüber hinaus trägt es zur Qualitätssteigerung bei, da der Abkühlungsprozess häufig unter kontrollierten Bedingungen stattfindet. Dies kann dazu beitragen, die Struktur und Eigenschaften des Stahls zu verbessern.

Zusammenfassung und Schlussfolgerungen

Das Verfahren des Ingot Casting ist ein zentraler Prozess in der Stahlproduktion und im Stahlhandel. Es ermöglicht die Herstellung von Ingots, die eine flexible Grundlage für die weitere Produktion von Stahlprodukten darstellen. Durch seine Effizienz und seinen Beitrag zur Qualitätssteigerung ist das Ingot Casting ein unverzichtbarer Schritt in der Stahlindustrie.

Blog Posts with the term: Ingot casting

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

Steel manufacturing from scrap is a sustainable process that reduces environmental impact and conserves resources. It involves collection, separation, melting in an electric arc furnace, refining to remove impurities, adding alloy elements, and casting into new products; recycling steel offers...

India's steel industry utilizes rich iron ore resources and advanced technology, adopting innovative methods like automation for efficient production. Government policies support sustainable practices in this key economic sector that drives growth and employment....

The article provides a comprehensive guide to steel production, simplifying core concepts for beginners and detailing key processes such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) methods. It covers essential steps from ironmaking to finishing, offering...

A steel product is an item predominantly made of steel, known for its durability and versatility across industries, with a wide range of forms and applications. Understanding these products involves knowledge of the production process from raw materials to finished...

Steel making machines have revolutionized the industry by increasing production speed, improving quality, and enabling precise designs through automation and advanced technology. Automation in steel production has evolved from manual processes to sophisticated machinery that enhances efficiency, safety, and sustainability...

Steel manufacturing is a complex, multi-stage process that transforms raw materials into the durable metal essential for modern infrastructure. It begins with extracting iron ore and progresses through various phases including blast furnace operation and primary steelmaking methods like Basic...

Steel production is a complex process combining traditional methods and modern technology to transform raw materials into versatile, durable products essential for industries like construction, automotive, energy, and consumer goods. Its adaptability ensures steel remains vital in innovation and sustainable...

Steel production technology has evolved significantly, with the industry now using advanced methods like blast furnaces and electric arc furnaces to meet global demands. Technological improvements have enhanced quality, efficiency, and sustainability in steel making. The future of steel production focuses...

Steel making techniques have evolved to become more efficient and environmentally friendly, with traditional methods like the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) being complemented by innovative technologies such as the Hydrogen Reduction Method. These advancements aim...

The article explores the steel industry's complexity, highlighting PDFs as essential guides for understanding processes like raw material preparation, ironmaking, and refining. It emphasizes the blast furnace's critical role in transforming raw materials into molten iron through efficient chemical reactions...

The article provides an in-depth look at the steelmaking process, covering its history from ancient methods to modern techniques like the Bessemer and Siemens-Martin processes. It details key stages such as raw material preparation, primary and secondary steelmaking, casting, shaping,...