Lime

Lime

Was ist Lime in Bezug auf Stahlproduktion und Stahlhandel?

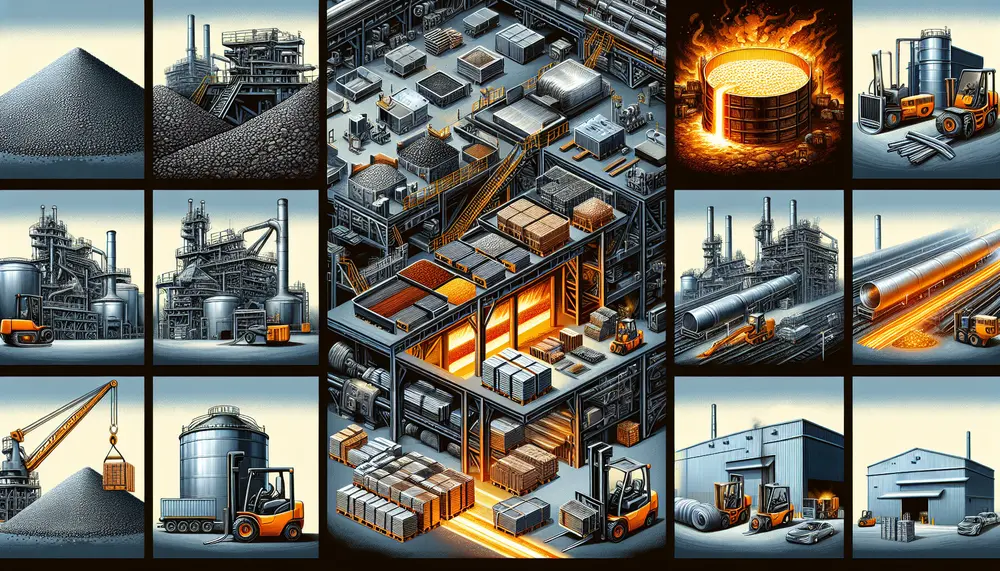

In der Welt der Stahlproduktion und des Stahlhandels ist 'Lime' ein Begriff, der sich auf gebrannten oder gelöschten Kalk bezieht. Kalk, chemisch als Calciumcarbbonat bekannt, spielt eine wesentliche Rolle bei der Herstellung von Stahl.

Die Bedeutung von Lime in der Stahlindustrie

Lime ist ein unerlässlicher Bestandteil bei der Herstellung von Stahl. Es ist sowohl ein Fluxmittel als auch ein Reinigungsmittel. Es hilft dabei, unerwünschte Verunreinigungen wie Silizium, Phosphor und Schwefel aus dem Eisen zu entfernen. Darüber hinaus wird Lime auch als Schutzbeschichtung verwendet, die den Ofen vor Schäden schützen kann.

Wie wird Lime in der Stahlproduktion eingesetzt?

Lime wird in der Stahlindustrie großflächig eingesetzt. Bei der Roheisenherstellung wird Kalkstein, eine natürliche Form von Lime, mit dem Erz und Koks im Hochofen vermischt. Der dabei entstandene Kalk reagiert mit den Verunreinigungen im Erz und bildet Schlacke. Diese Schlacke kann anschließend abgeschöpft und entsorgt oder weiterverarbeitet werden.

Lime im Stahlhandel

Lime hat auch im Stahlhandel seinen Platz. Händler von Rohstoffen für die Stahlproduktion haben auch Lime in ihrem Sortiment, da es eine wesentliche Zutat im Herstellungsprozess ist. Daher sind Informationen über Lime, dessen Qualität und Preis, für Stahlhändler von großer Bedeutung.

Zusammenfassung

Obwohl Lime möglicherweise nicht das erste ist, was einem in den Sinn kommt, wenn man an Stahl denkt, spielt es eine enorm wichtige Rolle in der Stahlproduktion und dem Stahlhandel. Durch seine vielfältige Rolle in der Produktion, von der Entfernung unerwünschter Verunreinigungen bis hin zur Schutz des Hochofens, ist Lime ein unverzichtbarer Bestandteil der Stahlindustrie.

Blog Posts with the term: Lime

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

The article provides an overview of the two main steelmaking routes: blast furnace (BF) and electric arc furnace (EAF), detailing their processes, economic considerations, environmental impacts, and technological advancements. It compares BF's large-scale production with high carbon emissions to EAF's...

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

The article "Introduction to Steelmaking from Pig Iron" explores the historical and modern processes of transforming pig iron into steel, including methods like the Bessemer Process, Basic Oxygen Steelmaking (BOS), and Electric Arc Furnace (EAF). It highlights the importance of...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The steelmaking industry is increasingly using natural gas to improve efficiency and reduce environmental impact. Natural gas serves as a reducing agent in Direct Reduced Iron (DRI) processes, partially replaces coke in blast furnaces, fuels various types of industrial furnaces,...

Steel production, a complex process involving several stages from mining of raw materials to creation of the final product, significantly impacts the price and sustainability of steel. Understanding this value chain is crucial for decision-making in the industry as it...

The Open Hearth Process is a traditional steelmaking method that involves converting iron into steel using an open hearth furnace, which allows air to flow over the mixture and facilitates chemical reactions necessary for purification. This process utilizes regenerative heating...

Steel making involves complex chemical reactions to transform raw materials into high-quality steel, primarily through oxidation and reduction processes. Oxygen plays a crucial role in oxidizing impurities like carbon, silicon, manganese, and phosphorus, which are then removed as gases or...

The article provides an overview of steel making, detailing its historical evolution and main processes such as ironmaking, primary and secondary steelmaking, casting, and forming; it highlights the importance of methods like the basic oxygen process and electric arc furnace...

The VOD (Vacuum-Oxygen-Decarburization) steelmaking process is essential for producing high-quality stainless steel with very low carbon levels, crucial for applications like medical instruments and aerospace components. While it offers advantages such as enhanced decarburization and protection of alloying elements, its...