Limestone

Limestone

Was ist Limestone?

Der Begriff Limestone, auch bekannt als Kalkstein, ist ein natürlich vorkommendes Sedimentgestein, das sich hauptsächlich aus Calciumcarbonat zusammensetzt. Dieses Gestein wird normalerweise im Meer oder in Seen gebildet, durch die Ablagerung von Schalen, Korallen und Algen.

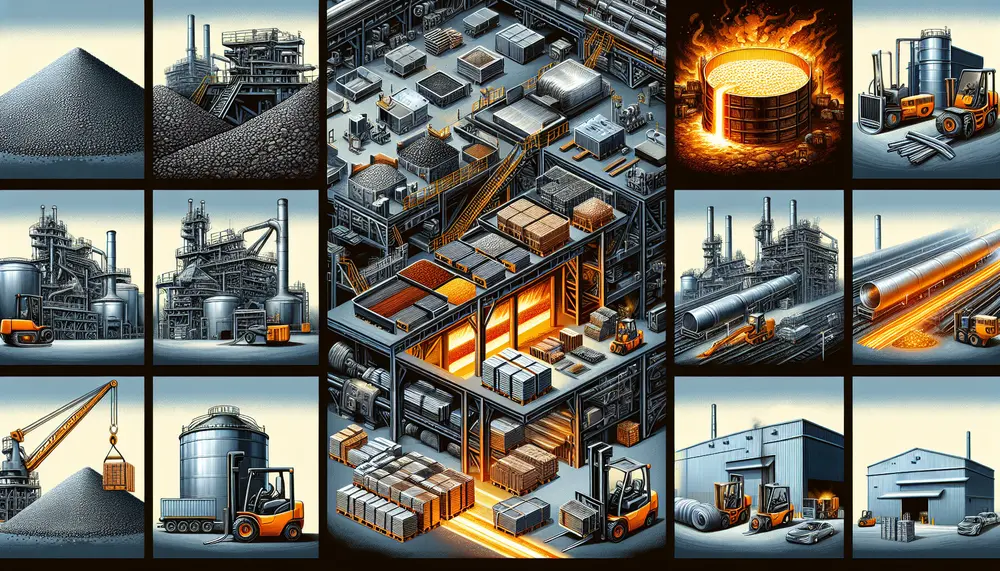

Die Rolle von Limestone in der Stahlproduktion

Im Kontext der Stahlproduktion hat Limestone eine entscheidende Rolle. Es dient als Flussmittel im Hochofen, wobei es hilft, die Eisenoxid-Erze in Metall zu reduzieren. Darüber hinaus ist Limestone auch verantwortlich für die Entfernung von Schlacke, das Abfallprodukt des Erzschmelzprozesses. Hier wird der Kalkstein zur Schmelze hinzugefügt, wodurch sich das Calciumcarbonat in Calciumsilikat umwandelt. Diese Verbindung verbindet sich mit anderen Abfallmaterialien und bildet die Schlacke, die dann leicht vom Metall getrennt werden kann.

Limestone im Stahlhandel

Im Stahlhandel spielt Limestone eine weniger direkte, aber ebenso wichtige Rolle. Da die Qualität und Effizienz der Stahlproduktion stark von der Qualität des verwendeten Limestone abhängig ist, sind die Preise und Verfügbarkeit von Limestone ein wichtiger Faktor im Stahlhandel. Ein hoher Kalksteingehalt im Erz kann den Preis des Stahls erhöhen, da weniger Erz benötigt wird, um die gleiche Menge an Stahl zu produzieren.

Blog Posts with the term: Limestone

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

The article provides an overview of the two main steelmaking routes: blast furnace (BF) and electric arc furnace (EAF), detailing their processes, economic considerations, environmental impacts, and technological advancements. It compares BF's large-scale production with high carbon emissions to EAF's...

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...

Steel production, a complex process involving several stages from mining of raw materials to creation of the final product, significantly impacts the price and sustainability of steel. Understanding this value chain is crucial for decision-making in the industry as it...

The Open Hearth Process is a traditional steelmaking method that involves converting iron into steel using an open hearth furnace, which allows air to flow over the mixture and facilitates chemical reactions necessary for purification. This process utilizes regenerative heating...

Steel making involves complex chemical reactions to transform raw materials into high-quality steel, primarily through oxidation and reduction processes. Oxygen plays a crucial role in oxidizing impurities like carbon, silicon, manganese, and phosphorus, which are then removed as gases or...

The article provides an overview of steel making, detailing its historical evolution and main processes such as ironmaking, primary and secondary steelmaking, casting, and forming; it highlights the importance of methods like the basic oxygen process and electric arc furnace...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

The blast furnace steel making process involves transforming raw materials into molten iron, which is then processed to produce steel. Key components include coke, iron ore and limestone; the former provides heat while the latter two undergo chemical reactions in...

Steel making technology has evolved from primitive forges to modern, efficient mills using methods like the Blast Furnace and Electric Arc Furnace (EAF), which recycles scrap metal. Recent innovations aim at enhancing efficiency and sustainability with developments such as advanced...