Mechanical Properties

Mechanical Properties

Was sind die Mechanical Properties?

Im Kontext der Stahlproduktion und des Stahlhandels bezieht sich der Begriff Mechanical Properties auf die Art und Weise, wie Stahl auf physische Kräfte reagiert und sich darunter verformt. Sie sind entscheidend für die Bestimmung der Anwendungen und Verwendungen von Stählen.

Messung der Mechanical Properties

Festigkeit, Dehnbarkeit, Härte, Zähigkeit und Duktilität sind analysierbare Mechanical Properties. Durch verschiedene Tests lassen sie sich messen. Dazu gehört etwa der Zugfestigkeitstest, der Auskunft darüber gibt, wie ein Stahlgebilde auf Zugspannung reagiert. Ein Härteprüfung hingegen misst die härtesten Qualitäten eines Stahls.

Warum sind Mechanical Properties wichtig?

Die Mechanical Properties eines Stahlprodukts beeinflussen direkt dessen Leistung und Langlebigkeit. Sie bestimmen beispielsweise, ob ein Stahlrohr den hohen Druck in einer Ölpipeline aushalten kann. Oder ob eine Stahlbrücke das Gewicht des darüber fahrenden Verkehrs tragen kann. Die Kenntnis dieser Eigenschaften ist daher entscheidend für Ingenieure und Architekten.

Weitere Anwendungsbereiche der Mechanical Properties

In der Stahlproduktion und -handel nutzen Hersteller die Mechanical Properties, um die Qualität ihrer Produkte zu garantieren. Sie nutzen sie ebenfalls, um kundenspezifische Stahlanforderungen zu erfüllen.

Im Stahlhandel sind die Mechanical Properties wichtige Spezifikationen. Sie helfen den Kunden dabei, den richtigen Stahl für ihre spezifischen Anforderungen auszuwählen.

Zusammenfassung: Mechanical Properties in Stahlproduktion und -handel

Zusammenfassend lassen sich die Mechanical Properties als die physikalischen Charakteristika von Stahl beschreiben, die dessen Verhalten unter verschiedenen Bedingungen bestimmen. Sie sind von zentraler Bedeutung für die Qualität, Leistung und Anwendung von Stahlprodukten in jeder Branche.

Blog Posts with the term: Mechanical Properties

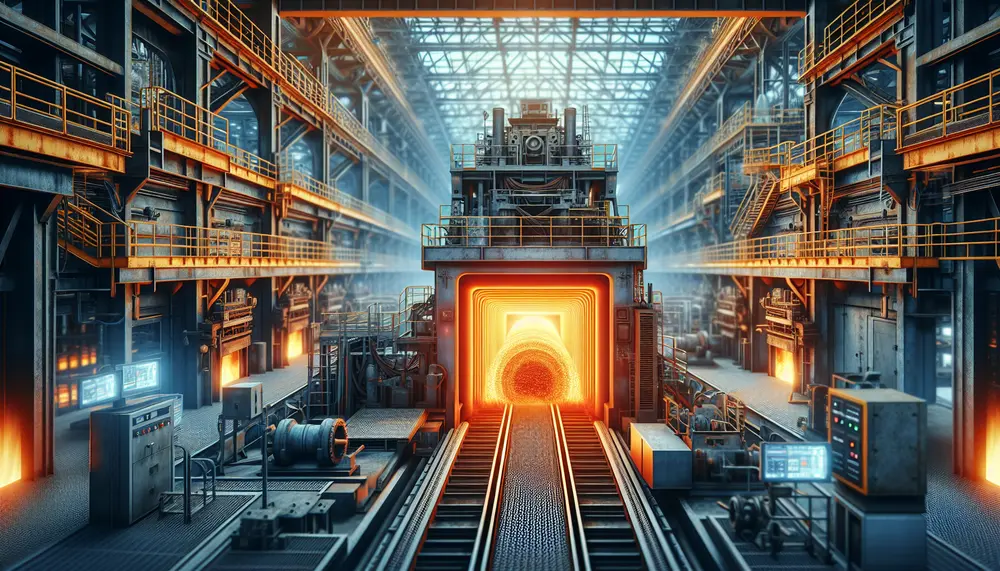

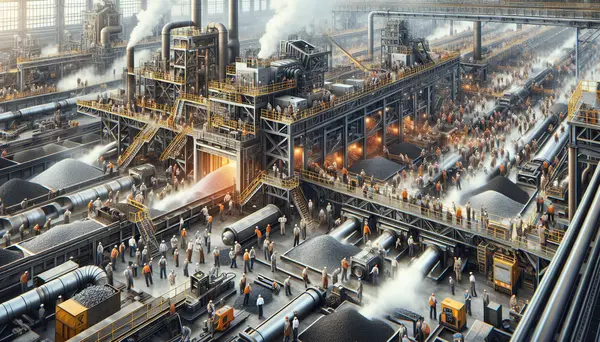

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...

Steel making involves complex chemical reactions to transform raw materials into high-quality steel, primarily through oxidation and reduction processes. Oxygen plays a crucial role in oxidizing impurities like carbon, silicon, manganese, and phosphorus, which are then removed as gases or...

The article provides an overview of steel making, detailing its historical evolution and main processes such as ironmaking, primary and secondary steelmaking, casting, and forming; it highlights the importance of methods like the basic oxygen process and electric arc furnace...

Induction furnaces have transformed steel making with their efficiency, versatility, and reduced environmental impact compared to traditional fossil fuel-based furnaces. They use electromagnetic induction for heating metals precisely and quickly, offering benefits like energy savings, improved productivity, metallurgical control, scalability,...

Lime is crucial in steelmaking, acting as a flux to remove impurities like phosphorus and sulfur, enhancing the quality of steel produced through processes such as EAF and BOF while also contributing to environmental sustainability by reducing emissions....

The iron and steel industry is undergoing a new era of innovation, driven by advancements in automation, energy efficiency, and carbon reduction. Key trends include the use of AI and IoT for fully automated plants, advanced production technologies that require...

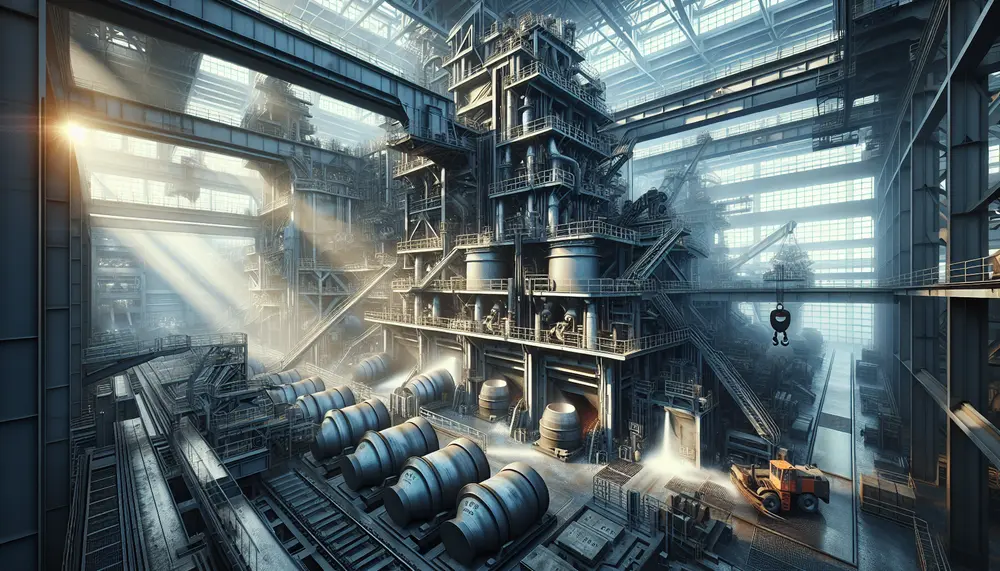

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...

Steelmaking ladles are essential in the steel production process, designed to transport and refine molten metal while withstanding extreme temperatures and chemical corrosion. They come in various types tailored for specific functions such as transferring, treating, casting, and precise pouring...

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...

Steelmaking flux is crucial in producing high-quality steel, acting as a cleansing agent to remove impurities and enhance the metal's properties. Different types of fluxes are used for specific tasks during production, impacting impurity removal and refining processes while protecting...

Desulfurization in steelmaking is crucial for producing high-quality, durable steel by removing sulfur impurities that cause brittleness; advancements and techniques like desulfurizing agents, slag optimization, and vacuum treatment enhance this process while addressing challenges such as cost and environmental concerns....

The Argon Oxygen Decarburization (AOD) process is essential in producing high-quality stainless steel by refining molten steel to reduce carbon content while preserving valuable alloying elements like chromium. This method, involving precise control of gas mixtures and temperatures during decarburization,...