Molybdenum

Molybdenum

Was ist Molybdän?

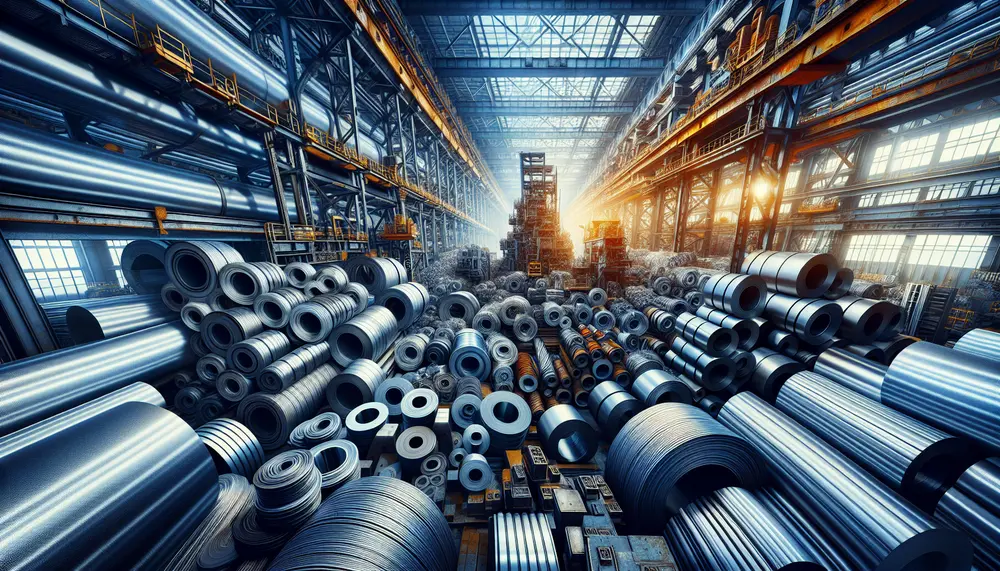

In der Welt der Stahlproduktion und des Stahlhandels ist Molybdän, oder oft nur "Moly", ein unverzichtbares Element. Molybdän ist ein silberfarbenes Metall, das auf dem Periodensystem als Mo bekannt ist. Es ist bekannt für seine außergewöhnliche Festigkeit und Hitzebeständigkeit, was es zu einem idealen Zusatzstoff für die Stahlproduktion macht.

Die Rolle des Molybdäns in der Stahlproduktion

In der Stahlproduktion spielt Molybdän eine Schlüsselrolle. Es wird verwendet, um den Stahl hitzebeständig und korrosionsbeständig zu machen. Durch das Hinzufügen von Molybdän in kleinen Mengen zu Stahl bildet sich eine harte, strapazierfähige Legierung, die hohen Temperaturen standhält. So trägt Molybdän dazu bei, den Stahl langlebiger, sicherer und zuverlässiger zu machen.

Molybdän im Stahlhandel

Im Stahlhandel ist die Nachfrage nach Molybdän-Stahl groß. Aufgrund seiner Eigenschaften wird Molybdän-Stahl in vielen Industrien eingesetzt, darunter die Automobil-, Flugzeug- und Bauindustrie. Da Molybdän den Stahl sowohl härter als auch hitzebeständiger macht, ist es ein begehrtes Gut auf dem Markt.

Zusammenfassung

Ob in der Automobilindustrie, im Flugzeugbau oder in Hochhausbauten, Molybdän spielt in der Stahlproduktion und im Stahlhandel eine wesentliche Rolle. Durch seine Härte und Hitzebeständigkeit erhöht Molybdän die Langlebigkeit und Sicherheit von Stahlprodukten und macht sie so zu einer bevorzugten Wahl in einer Reihe von Industriezweigen. Die Nachfrage nach Molybdän im Stahlhandel unterstreicht seine Bedeutung in dieser Branche.

Blog Posts with the term: Molybdenum

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...

Steel production relies on a balance of raw materials like iron ore, coal, limestone, and scrap metal to determine the characteristics of different steel types. Understanding these ingredients is crucial for industry professionals as they influence strength, durability, and quality...

The steelmaking process involves complex chemical reactions to transform iron ore into steel, an alloy primarily made of iron and carbon. The Basic Oxygen Steelmaking (BOS) method is the most common way to produce steel, where a high-purity stream of...

Steel is an iron-carbon alloy with varying carbon content that determines its hardness, ductility, and tensile strength; other elements like chromium can be added to enhance specific properties such as corrosion resistance. Steel products are categorized into four main types:...

Steel production is a complex process combining traditional methods and modern technology to transform raw materials into versatile, durable products essential for industries like construction, automotive, energy, and consumer goods. Its adaptability ensures steel remains vital in innovation and sustainable...

Stainless steel making is a complex process that begins with melting iron ore and other elements like chromium and nickel to create a durable, corrosion-resistant material. This involves several stages including refining, casting, and rolling, controlled by precise temperature and...

Steelmaking transforms iron ore into steel, involving processes like smelting and primary steelmaking methods such as Basic Oxygen Steelmaking (BOS) or Electric Arc Furnace (EAF), with additives enhancing properties. Understanding these basics aids in mastering industry-specific terminology crucial for various...

Steel is a versatile material essential to modern industry, with various grades tailored for specific uses from construction to technology. Its key advantages include durability, resistance to extreme conditions, and recyclability, making it integral in innovation and sustainability efforts across...

The concept of steelmaking grade is crucial in determining the quality and properties of steel, influencing efficiency, durability, and safety across various industries. Steel grades are classified based on chemical composition and production processes, with advancements in technology and global...

The article explores the steel industry's complexity, highlighting PDFs as essential guides for understanding processes like raw material preparation, ironmaking, and refining. It emphasizes the blast furnace's critical role in transforming raw materials into molten iron through efficient chemical reactions...

Steel making hammers are essential tools designed for durability, precision, and efficiency in metalworking processes, with various types tailored to specific tasks. Choosing the right hammer type and material ensures enhanced productivity, longevity, and craftsmanship quality in steel forging applications....

A well-structured PowerPoint on stainless steel manufacturing uses clear visuals and icons to simplify complex processes, enhance understanding, and support actionable insights....

Steel products manufacturing transforms raw materials into essential items for modern life, involving a process from conceptualization to final product creation. The steel making process is an intricate journey that includes extraction of iron ore, refining in blast furnaces or...

Wootz steel, originating in ancient southern India, was renowned for its unique microstructure and exceptional performance, fueling centuries of global trade and legend....