Oxidation

Oxidation

Was ist Oxidation?

Die Oxidation ist ein chemischer Prozess, der eine wichtige Rolle in der Stahlproduktion und dem Stahlhandel spielt. Grundsätzlich ist Oxidation die Interaktion zwischen Sauerstoffmolekülen und allen verschiedenen Substanzen, die sie bei diesem Prozess treffen können. In Bezug auf die Stahlproduktion geschieht dies, wenn Sauerstoff auf Eisen trifft, was zur Bildung von Eisenoxid, besser bekannt als Rost, führt.

Oxidation in der Stahlproduktion

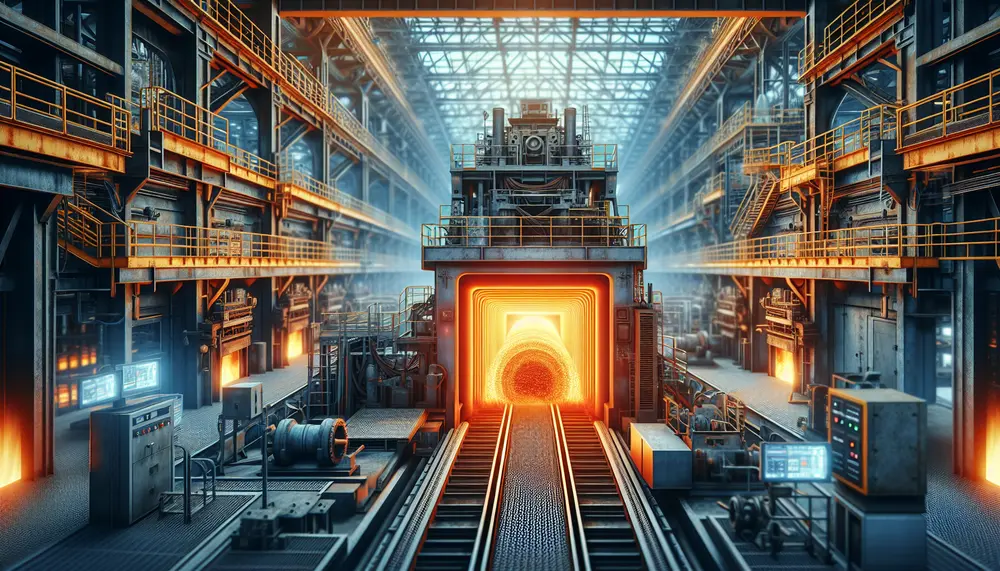

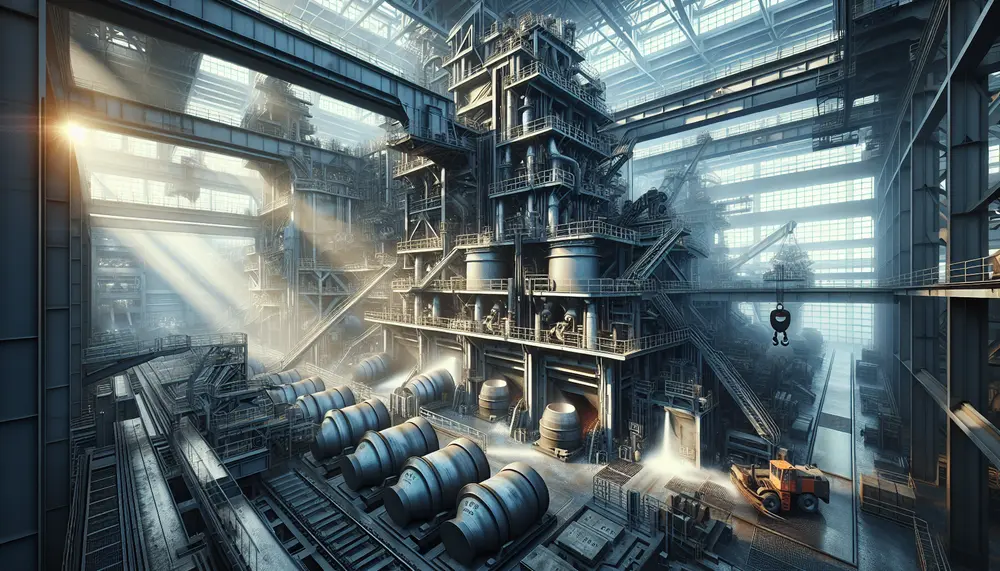

In der Stahlproduktion spielt die Oxidation eine Schlüsselrolle bei der Gewinnung von reinem Eisen aus Eisenerz. Der Oxidationsprozess hilft, unerwünschte Elemente wie Silizium, Mangan und Phosphor zu entfernen, die die Qualität des Stahls beeinträchtigen können. Dieser „Reinigungs“-Prozess findet im Hochofen statt, wo die hohe Temperatur die Oxidation dieser Elemente erleichtert.

Oxidation und Rostbildung

Die Oxidation ist auch verantwortlich für das Phänomen, das wir als Rost kennen. Wenn der fertige Stahl nicht vor Feuchtigkeit geschützt ist, kann die Feuchtigkeit auf die Oberfläche des Stahls gelangen und eine Oxidation verursachen, die als Rost erscheint und die Festigkeit des Materials erheblich verringert. Das Verständnis und die Kontrolle der Oxidationsprozesse sind daher entscheidend, um die Qualität und Haltbarkeit von Stahlprodukten zu gewährleisten.

Vermeidung von Oxidation

Es gibt verschiedene Techniken, um die Oxidation und damit die Rostbildung auf Stahloberflächen zu verhindern. Dazu gehören die Verwendung von Rostschutzfarben und -lacken, das Aufbringen von Zinküberzügen (Galvanisieren), die Anwendung elektrochemischer Techniken (wie die kathodische Schutz) und vieles mehr. Die Wahl der besten Methode hängt von verschiedenen Faktoren ab, einschließlich der Art des Stahls, seiner Verwendung und der vorherrschenden Umweltbedingungen.

Blog Posts with the term: Oxidation

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article "Introduction to Steelmaking from Pig Iron" explores the historical and modern processes of transforming pig iron into steel, including methods like the Bessemer Process, Basic Oxygen Steelmaking (BOS), and Electric Arc Furnace (EAF). It highlights the importance of...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...

Steel's origins trace back to meteoric iron and evolved with human discovery of smelting around 2500 BCE, leading from the Bronze Age into the Iron Age. The Bessemer Process in the mid-19th century revolutionized steel production, enabling mass production and...

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...

The Open Hearth Process is a traditional steelmaking method that involves converting iron into steel using an open hearth furnace, which allows air to flow over the mixture and facilitates chemical reactions necessary for purification. This process utilizes regenerative heating...

Steel making involves complex chemical reactions to transform raw materials into high-quality steel, primarily through oxidation and reduction processes. Oxygen plays a crucial role in oxidizing impurities like carbon, silicon, manganese, and phosphorus, which are then removed as gases or...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

The VOD (Vacuum-Oxygen-Decarburization) steelmaking process is essential for producing high-quality stainless steel with very low carbon levels, crucial for applications like medical instruments and aerospace components. While it offers advantages such as enhanced decarburization and protection of alloying elements, its...

Induction furnaces have transformed steel making with their efficiency, versatility, and reduced environmental impact compared to traditional fossil fuel-based furnaces. They use electromagnetic induction for heating metals precisely and quickly, offering benefits like energy savings, improved productivity, metallurgical control, scalability,...

The blast furnace steel making process involves transforming raw materials into molten iron, which is then processed to produce steel. Key components include coke, iron ore and limestone; the former provides heat while the latter two undergo chemical reactions in...

The article traces the history of steelmaking from early iron discoveries around 2,500 BCE to advanced techniques like Chinese cast iron production and Indian Wootz steel. It highlights key innovations such as smelting, forging by the Chalybes, and global influences...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...