Pig iron

Pig iron

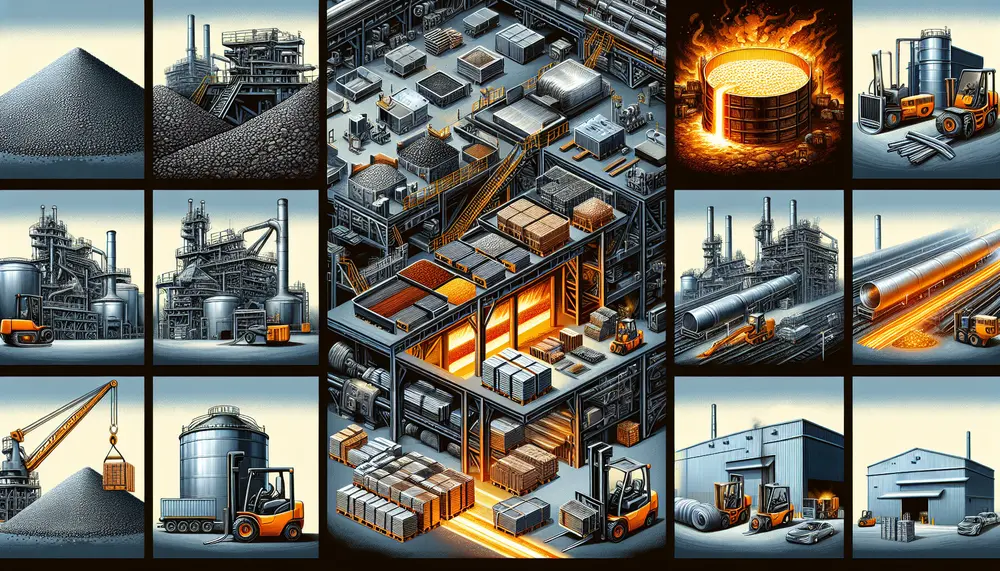

Pig iron: Was es ist und wie es entsteht

Pig iron ist ein grundlegendes Produkt in der Stahlindustrie. Den Namen erhält es aufgrund der traditionellen Form, in der es abgegossen wird. Es ähnelt kleinen Ferkeln, die an das Zentrum ihrer Mutter angedockt sind. Pig iron entsteht durch das Schmelzen von Eisenerz in einem Hochofen und wird hauptsächlich zur Herstellung von Stahl verwendet.

Wie wird Pig iron produziert?

Die Herstellung von Pig iron findet in Hochöfen statt. Dort wird Eisenerz bei extrem hohen Temperaturen geschmolzen, umgeschmolzen und mit Koks, einem Brennstoff mit hohem Kohlenstoffgehalt, kombiniert. Diese Kombination löst chemische Reaktionen aus, die Eisen und Schlacken, einen Abfallstoff, trennen. Was übrig bleibt, ist Pig iron, eine Art Roheisen mit hohem Kohlenstoffgehalt und zusätzlichen Elementen wie Silikon, Mangan, Schwefel und Phosphor.

Pig iron im Handel

Pig iron spielt eine wichtige Rolle im Stahlhandel. Es existiert ein globaler Markt für dieses Produkt, das an Stahlwerke und Gießereien auf der ganzen Welt verkauft wird. Diese nutzen Pig iron als Ausgangsmaterial für die Herstellung einer Vielzahl von Stahlprodukten. Die Marktpreise für Pig iron können stark schwanken, abhängig von Faktoren wie Nachfrage und Angebot, den Kosten für Rohmaterialien und Energie sowie globalen wirtschaftlichen Bedingungen.

Von Pig iron zu Stahl

Die Herstellung von Stahl aus Pig iron ist ein kritischer Prozess in der Stahlproduktion. Der hohe Kohlenstoffgehalt im Pig iron wird reduziert, in der Regel durch ein Verfahren namens Oxygen-Verfahren, um Stahl zu erzeugen. Durch weitere Verfahren kann der Stahl dann in viele verschiedene Typen und Qualitäten umgewandelt werden, die in einer Vielzahl von Anwendungen verwendet werden, vom Bau über die Automobilindustrie bis hin zu Haushaltsgeräten.

Zusammenfassung

Pig iron ist somit ein wichtiger Bestandteil in der Herstellung von Stahl. Es wird aus Eisenerz in einem Hochofen gewonnen und ist die Basis für eine Vielzahl von Stahlprodukten, die wir täglich in unserem Leben nutzen. Im Handel ist Pig iron ein globales Produkt, dessen Preis von einer Vielzahl von Faktoren beeinflusst wird.

Blog Posts with the term: Pig iron

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

The article provides an overview of the two main steelmaking routes: blast furnace (BF) and electric arc furnace (EAF), detailing their processes, economic considerations, environmental impacts, and technological advancements. It compares BF's large-scale production with high carbon emissions to EAF's...

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Mexico's steel industry has grown significantly due to rich resources, strategic location, skilled workforce, and modern technology. Challenges include high energy costs, competition from lower-cost countries, price fluctuations, and environmental concerns....

The article "Introduction to Steelmaking from Pig Iron" explores the historical and modern processes of transforming pig iron into steel, including methods like the Bessemer Process, Basic Oxygen Steelmaking (BOS), and Electric Arc Furnace (EAF). It highlights the importance of...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...

Steel's origins trace back to meteoric iron and evolved with human discovery of smelting around 2500 BCE, leading from the Bronze Age into the Iron Age. The Bessemer Process in the mid-19th century revolutionized steel production, enabling mass production and...

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...

Steel production, a complex process involving several stages from mining of raw materials to creation of the final product, significantly impacts the price and sustainability of steel. Understanding this value chain is crucial for decision-making in the industry as it...

The article provides an overview of steel making, detailing its historical evolution and main processes such as ironmaking, primary and secondary steelmaking, casting, and forming; it highlights the importance of methods like the basic oxygen process and electric arc furnace...