Quenching

Quenching

Einführung in das Quenching

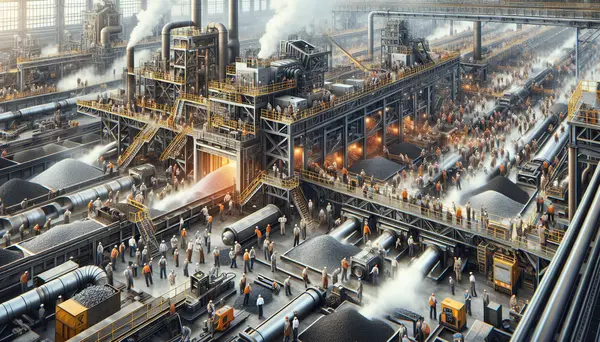

Beginnen wir mit der einfachen Frage: Was ist Quenching? Quenching ist ein Prozess in der Stahlherstellung, der dazu dient, die Härte eines Stahlerzeugnisses zu erhöhen. Es geschieht nach dem Erhitzen des Stahls, wo das Material schnell in eine Flüssigkeit - oft Wasser oder Öl - abgekühlt wird. Diese schnelle Abkühlung verändert die Struktur des Stahls, was ihn härter und widerstandsfähiger gegen Kratzer und Verschleiß macht.

Warum ist Quenching wichtig?

Quenching ist ein grundlegender Prozess in der Stahlproduktion und im Stahlhandel. Warum? Weil es das Endprodukt verbessert. In der Autoindustrie zum Beispiel, wo Stahlteile starken Belastungen ausgesetzt sind, ist der harte, widerstandsfähige Stahl, der durch Quenching erzeugt wird, sehr gefragt. Es erhöht die Lebensdauer der Stahlteile und reduziert die Wartungsanforderungen. Im Bauwesen ermöglicht Quenching die Herstellung von langlebigem, witterungsbeständigem Stahl. Es ist auch in vielen anderen Branchen unerlässlich.

Der Quenching-Prozess

Jetzt fragen Sie sich wahrscheinlich: Wie funktioniert Quenching? Der Prozess beginnt mit dem Erhitzen des Stahls auf eine sehr hohe Temperatur. Dies wird als "Austenitisieren" bezeichnet. In diesem Zustand verändert sich die Struktur des Stahls im Mikrobereich. Dann, in der kritischen Phase des Quenchings, wird der heiße Stahl schnell in die Kühlflüssigkeit getaucht. Dies führt zu einer schnellen Abkühlung und damit zu einer weiteren Strukturveränderung. Der Prozess endet mit der "Anlassbehandlung", bei der der Stahl erneut erhitzt wird, aber diesmal auf eine niedrigere Temperatur, um eventuelle Spannungen zu lösen und die Härte zu optimieren.

Zusammenfassung: Quenching in der Stahlproduktion und im Stahlhandel

Quenching ist somit ein essenzieller Prozess in der Stahlproduktion. Durch die Erhöhung der Haltbarkeit des Stahls ermöglicht es eine breitere Anwendung in einer Vielzahl von Branchen. Aber wie viele Prozesse in der Stahlfertigung erfordert auch das Quenching Fachwissen und Sorgfalt, um optimale Ergebnisse zu erzielen.

Blog Posts with the term: Quenching

Steel's origins trace back to meteoric iron and evolved with human discovery of smelting around 2500 BCE, leading from the Bronze Age into the Iron Age. The Bessemer Process in the mid-19th century revolutionized steel production, enabling mass production and...

Steel production is a highly energy-intensive process with significant environmental impacts, making the understanding and monitoring of energy consumption at each stage crucial for sustainability. Energy efficiency in steel manufacturing is essential for cost-effectiveness, competitiveness, and reducing carbon emissions, with...

Steel was crucial in World War II, serving as the backbone for military equipment and influencing nations' industrial might. The escalation of steel production played a pivotal role in the Allied victory, with advancements in technology and massive job creation. Steel's...

The manufacturing of steel balls is a complex process involving precise steps to produce high-quality products for various applications. It starts with selecting the right raw materials and includes forging, flashing, heat treating, grinding, lapping, and rigorous inspections to ensure...

The article "Introduction to Ancient Steel Making" explores the historical context, key techniques, and materials used in ancient steel production across various civilizations. It highlights how early methods influenced modern steel making and underscores the ingenuity of our ancestors in...

The iron and steel industry is undergoing a new era of innovation, driven by advancements in automation, energy efficiency, and carbon reduction. Key trends include the use of AI and IoT for fully automated plants, advanced production technologies that require...

Japanese steelmaking blends ancient traditions with modern innovations, producing some of the world's finest steel. This article explores its rich history from early Tatara furnaces to advanced techniques today, highlighting the craftsmanship and enduring legacy of Japanese steel production....

The article traces the evolution of steel making from its inception in the Iron Age to modern times. It highlights key milestones such as the Bronze Age's dawn of iron use, 17th century advancements in furnace technology and iron production,...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

Steel manufacturing from scrap is a sustainable process that reduces environmental impact and conserves resources. It involves collection, separation, melting in an electric arc furnace, refining to remove impurities, adding alloy elements, and casting into new products; recycling steel offers...

Steel is an iron-carbon alloy with varying carbon content that determines its hardness, ductility, and tensile strength; other elements like chromium can be added to enhance specific properties such as corrosion resistance. Steel products are categorized into four main types:...

Steel tube manufacturing is essential for industries like construction, energy, and transportation, offering seamless tubes for strength and welded ones for cost-efficiency. The processes involve precise engineering to ensure durability, versatility, and performance tailored to specific applications....

The article provides a comprehensive guide to steel production, simplifying core concepts for beginners and detailing key processes such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) methods. It covers essential steps from ironmaking to finishing, offering...

The art of medieval steelmaking combined intuition, tradition, and a deep understanding of metallurgy to create strong yet flexible materials essential for tools, weapons, and status symbols. Despite limited scientific knowledge and resources, artisans mastered techniques like carbon infusion and...