Tensile strength

Tensile strength

Einführung in die Zugfestigkeit

Wenn man sich mit Steel Production and Steel Trade beschäftigt, stößt man unweigerlich auf den Begriff 'Tensile Strength'. Aber was ist das genau?

Was ist Tensile Strength?

Der Begriff Zugfestigkeit, auch bekannt als Zugspannung, ist ein wichtiger Leistungsindikator für Stahl und andere Materialien. Einfach ausgedrückt, beschreibt es die Fähigkeit eines Materials, Dehnung und Zugbelastung zu widerstehen, ohne zu brechen.

Warum ist Tensile Strength wichtig?

Die Zugfestigkeit ist besonders wichtig im Bereich der Steel Production und Steel Trade. Qualitativ hochwertiger Stahl muss eine hohe Zugfestigkeit aufweisen, um in verschiedensten Anwendungen, etwa im Fahrzeugbau, der Konstruktion oder im Maschinenbau, bestehen zu können. Ein hoher Grad an Zugfestigkeit sorgt dafür, dass der Stahl nicht bricht, wenn er gezogen oder gestreckt wird.

Wie wird die Tensile Strength gemessen?

Die Zugfestigkeit wird in der Regel durch einen Zugversuch bestimmt. Hierbei wird ein Testmuster des Materials – bei Stahl meist ein Stab oder eine Platte – in einer Zugprüfmaschine platziert und mit stetig steigender Kraft gezogen, bis das Material zerbricht. Die bei der Zerstörung des Probenkörpers auftretende Belastung wird dann auf die ursprüngliche Querschnittsfläche der Probe bezogen. Das Ergebnis, ausgedrückt in N/mm², gibt die Zugfestigkeit des Materials an.

Fazit

Die Zugfestigkeit ist ein wichtiger Parameter in der Steel Production und Steel Trade und spielt eine entscheidende Rolle bei der Beurteilung der Qualität von Stahlprodukten. Ein hoher Zahlenwert für die Zugfestigkeit weist auf einen robusten und widerstandsfähigen Stahl hin, der auch unter hoher Belastung nicht bricht.

Blog Posts with the term: Tensile strength

Coke is crucial in steel production, providing heat and chemical reactions for smelting iron ore while also structuring the blast furnace. However, its use emits pollutants and CO2, contributing to environmental concerns....

Steel production in France has grown due to technological advancements, increased demand, and strategic investments despite challenges like environmental regulations and market volatility. The industry's history shows a pattern of expansion post-WWII, peak production in the 1970s, followed by decline...

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

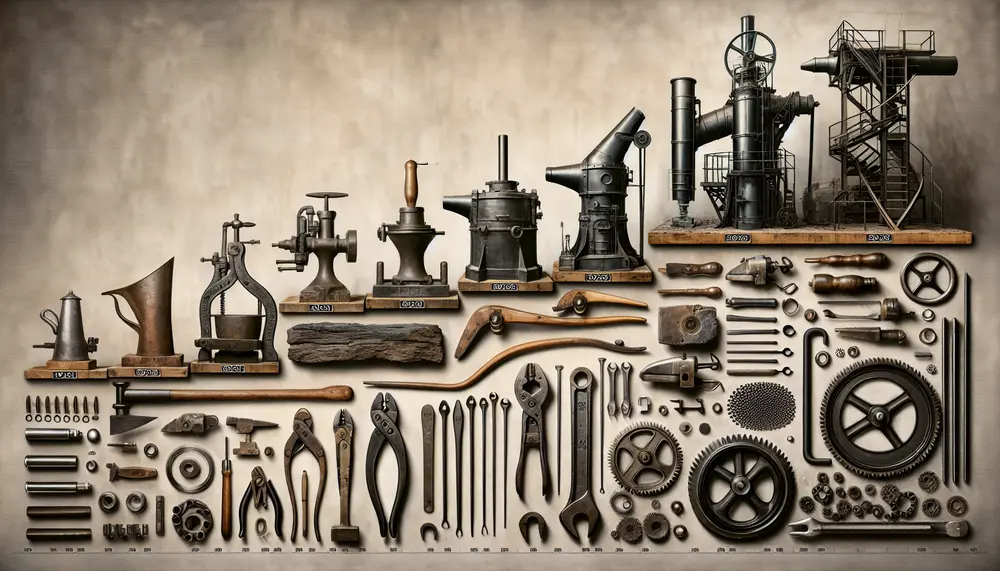

Steel's origins trace back to meteoric iron and evolved with human discovery of smelting around 2500 BCE, leading from the Bronze Age into the Iron Age. The Bessemer Process in the mid-19th century revolutionized steel production, enabling mass production and...

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...

Steel making involves complex chemical reactions to transform raw materials into high-quality steel, primarily through oxidation and reduction processes. Oxygen plays a crucial role in oxidizing impurities like carbon, silicon, manganese, and phosphorus, which are then removed as gases or...

Japan's steel industry rose from the post-WWII era to become a global leader through strategic investments in technology, quality control, and export-oriented policies. Key factors for this success include R&D commitment, high-quality standards, advantageous locations for trade routes, skilled workforce...

South Korea is a key player in the global steel market, known for its production capacity, innovation, and high-quality specialty steels. The industry's economic impact on Korea includes job creation and skill development while driving foreign investment and technological advancement;...

Steel making technology has evolved from primitive forges to modern, efficient mills using methods like the Blast Furnace and Electric Arc Furnace (EAF), which recycles scrap metal. Recent innovations aim at enhancing efficiency and sustainability with developments such as advanced...

Steelmaking flux is crucial in producing high-quality steel, acting as a cleansing agent to remove impurities and enhance the metal's properties. Different types of fluxes are used for specific tasks during production, impacting impurity removal and refining processes while protecting...

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...

Henry Bessemer revolutionized steel production in the 19th century with his innovative process, enabling mass production of stronger, affordable steel and fueling industrial growth. By efficiently removing impurities through oxygen blasts, his method drastically reduced costs and transformed steel into...

Steelmaking has evolved from early iron manipulation to advanced processes like the Bessemer method, which revolutionized mass steel production and infrastructure development. Technological advancements such as open hearth furnaces and electric arc furnaces further refined steel's properties, while British dominance...