Tundish

Tundish

Was ist ein Tundish?

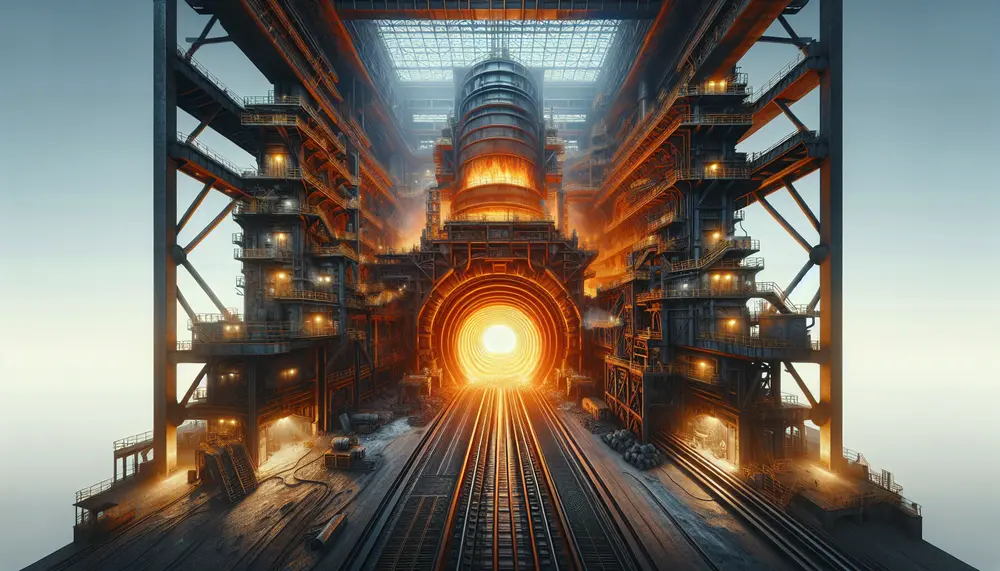

Der Tundish ist ein wichtiges Element in der Stahlproduktion und im Stahlhandel. Er ist ein großes, offenes Gefäß, das ein kritisches Glied zwischen den Schmelzöfen und den endgültigen Gießformen ist. Er spielt eine entscheidende Rolle bei der Aufrechterhaltung einer gleichmäßigen und kontinuierlichen Stahlzufuhr, während er gleichzeitig als Puffer und Filter dient.

Funktion eines Tundish

Die Hauptfunktion eines Tundish besteht darin, das flüssige Metall aus dem Schmelzofen gleichmäßig in kleinere Ströme aufzuteilen, um es in die Gießformen zu leiten. Dabei entfernt er auch grobe Verunreinigungen und eingeschlossene Schlackenpartikel aus dem flüssigen Stahl. Dies verbessert die endgültige Qualität des Stahls.

Design und Konfiguration des Tundish

Das Design und die Anordnung eines Tundish können erheblichen Einfluss auf die Effizienz der Stahlproduktion haben. Typischerweise sind sie so konzipiert, dass sie den natürlichen Fluss des Metalls unterstützen und Turbulenzen vermeiden, die zur Verunreinigung des Stahls führen könnten. In einigen Fällen können Tundishes so konzipiert sein, dass sie zusätzliche Prozesse, wie z.B. die Zugabe von Legierungselementen oder die Durchführung von Schlackenbehandlungen, unterstützen.

Wichtige Rolle in der Stahlproduktion und im Stahlhandel

Der Tundish spielt eine zentrale Rolle in der Stahlproduktion und im Stahlhandel als letzter Puffer und gleichzeitig wichtigste Kontrollinstanz zwischen dem Schmelzofen und den Gießformen. Eine korrekte Nutzung und Wartung des Tundish kann dazu beitragen, Produktivitätsverluste zu vermeiden und die Produktqualität zu verbessern, was im Endeffekt die Rentabilität der Anlage steigert.

Blog Posts with the term: Tundish

The Open Hearth Process is a traditional steelmaking method that involves converting iron into steel using an open hearth furnace, which allows air to flow over the mixture and facilitates chemical reactions necessary for purification. This process utilizes regenerative heating...

Steelmaking oxidation is a critical process in steel production, involving the intentional addition of oxygen to molten iron to trigger chemical reactions that remove impurities like carbon, silicon, and phosphorus, thereby enhancing the quality and properties of steel. This process...

Direct Reduced Iron (DRI), crucial for sustainable steelmaking, offers an eco-friendlier alternative to traditional methods by using natural gas or hydrogen, reducing CO2 emissions and enhancing steel quality. Steel production has evolved significantly from the Bessemer process to modern techniques...

Steel making machines have revolutionized the industry by increasing production speed, improving quality, and enabling precise designs through automation and advanced technology. Automation in steel production has evolved from manual processes to sophisticated machinery that enhances efficiency, safety, and sustainability...

Steelmaking transforms iron ore into steel, involving processes like smelting and primary steelmaking methods such as Basic Oxygen Steelmaking (BOS) or Electric Arc Furnace (EAF), with additives enhancing properties. Understanding these basics aids in mastering industry-specific terminology crucial for various...

The article explores the steel industry's complexity, highlighting PDFs as essential guides for understanding processes like raw material preparation, ironmaking, and refining. It emphasizes the blast furnace's critical role in transforming raw materials into molten iron through efficient chemical reactions...

The steelmaking tundish is a critical intermediary in the continuous casting process, serving as both a reservoir and buffer for molten steel while facilitating controlled flow and cleanliness to enhance final product quality. Its design has evolved since the 1950s,...

Steelmaking transforms iron into steel by increasing carbon content and refining the material through methods like blast furnaces and adding additives. Modern techniques include Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), focusing on sustainability, with raw materials such...

The steel production casting process involves melting raw materials, refining the molten metal, and pouring it into molds to shape solid products with controlled cooling to prevent defects. The variety of cast steels is determined by carbon content and alloying...

Steel, an alloy primarily composed of iron and carbon, is created by manipulating the quantities and types of these elements to create a range with different properties. The production process involves extracting iron from its ore, converting it into steel...

The article discusses the importance of understanding and optimizing key metrics in steelmaking yield, such as Gross Yield, Net Yield, and Yield Loss, to improve efficiency and sustainability. It also highlights factors influencing yield like raw material quality and technological...

Steelmaking refractories are crucial materials that withstand extreme conditions to facilitate steel production, enhancing the efficiency, safety, and cost-effectiveness of processes while ensuring product quality. They face challenges like high temperature fluctuations and corrosive environments but advancements in technology continue...

Advanced machinery has revolutionized steel production by increasing precision, speed, and control in processes like melting and shaping metals. Automation and digital controls have improved safety, quality consistency, and operational efficiency through data analysis. The evolution of steel production machinery from...

The article discusses the significance of names in steel manufacturing processes, which often reflect their inventors, locations, or characteristics and serve as a historical timeline of industry advancements. It also outlines how terminology has evolved with technology and globalization, providing...

Steelmaking nouns are essential for clear communication and safety in the steel industry, with evolving terminology requiring an up-to-date glossary. This article explains key terms like alloy, arc furnace, austenite, blast furnace, billet, basic oxygen process, carbon content, converter, casting,...