Ultrasonic Testing

Ultrasonic Testing

Was ist Ultrasonic Testing?

Wenn es um die Qualitätssicherung in der Stahlproduktion und im Stahlhandel geht, spielt das sogenannte Ultrasonic Testing oder Ultraschallprüfung eine entscheidende Rolle. Dabei handelt es sich um eine nicht-invasive Prüftechnik. Sie verwendet hochfrequente Schallwellen, um Materialdefekte oder Veränderungen in den Eigenschaften von Materialien zu erkennen.

Wie funktioniert Ultrasonic Testing?

Die Methode des Ultrasonic Testing basiert auf dem Prinzip der Schallreflexion. Hier kommen Ultraschallsensoren zum Einsatz, die Hochfrequenz-Schallwellen aussenden. Diese Wellen durchdringen das Material und reflektieren zurück, wenn sie auf eine Unstimmigkeit stoßen. Die Sensoren nehmen die reflektierten Wellen auf und dies ermöglicht eine akkurate Beurteilung der Materialstruktur.

Wann setzt man Ultrasonic Testing ein?

In der Stahlproduktion und im Stahlhandel ist das Ultrasonic Testing besonders nützlich. Hier gibt es vielfältige Anwendungsmöglichkeiten. Oft nutzt man es zur Prüfung von Stahlerzeugnissen auf innere Risse oder zur Beurteilung der Material-Mikrostruktur. Auch die Dicke von Stahlplatten lässt sich mittels ultrasonic testing bestimmen. Darüber hinaus findet es Anwendung bei der Prüfung von Schweißnähten, um deren Qualität sicherzustellen.

Welche Vorteile bietet Ultrasonic Testing?

Einer der größten Vorteile des Ultrasonic Testing ist seine Nicht-Invasivität. Das bedeutet, dass der Prüfprozess das Material nicht beschädigt. Das mach diesen Prüfprozess besonders kosteneffizient. Zudem zeichnet sich die Ultraschallprüfung durch ihre hohe Genauigkeit aus, mit der sie sogar kleinste Defekte im Material aufdecken kann. Dies kann zur Vermeidung von kostspieligen und gefährlichen Materialversagen beitragen.

Blog Posts with the term: Ultrasonic Testing

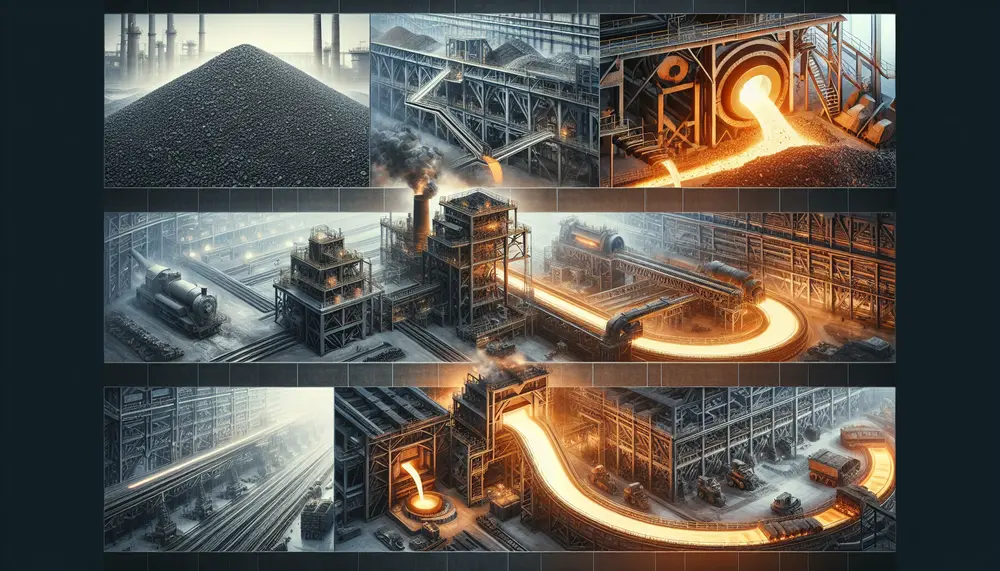

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Steelmaking rolling is a crucial process that transforms raw steel into various usable forms by passing it through rollers to reduce thickness, improve uniformity, and achieve specific mechanical properties. The article details the stages of hot and cold rolling, the...

Steel tube manufacturing is essential for industries like construction, energy, and transportation, offering seamless tubes for strength and welded ones for cost-efficiency. The processes involve precise engineering to ensure durability, versatility, and performance tailored to specific applications....

Steel fabrication involves transforming raw steel into structures or products using various techniques like cutting, bending, and joining to ensure strength and quality. Material selection is critical in this process as it affects the performance and longevity of the final...

The steel making process transforms iron ore into a vital and robust material through complex technical procedures, reflecting human ingenuity and progress. This journey from extraction to the final product involves meticulous steps including smelting in blast furnaces, oxidation for...

Stainless steel making is a complex process that begins with melting iron ore and other elements like chromium and nickel to create a durable, corrosion-resistant material. This involves several stages including refining, casting, and rolling, controlled by precise temperature and...

Steelmaking transforms iron ore into steel, involving processes like smelting and primary steelmaking methods such as Basic Oxygen Steelmaking (BOS) or Electric Arc Furnace (EAF), with additives enhancing properties. Understanding these basics aids in mastering industry-specific terminology crucial for various...

The steel production casting process involves melting raw materials, refining the molten metal, and pouring it into molds to shape solid products with controlled cooling to prevent defects. The variety of cast steels is determined by carbon content and alloying...

Steelmaking is a complex process involving several critical steps, from extracting iron to refining and shaping it into high-quality steel. Key stages include ironmaking, primary and secondary steelmaking, casting, forming, finishing, selecting appropriate materials like iron ore and coke, and...

The article provides an in-depth look at the steel production process, from raw material extraction to finished product. It highlights key stages such as ironmaking, steelmaking, casting, hot and cold rolling, finishing; emphasizing the role of technology in improving efficiency...

Metal manufacturing involves techniques like forming, machining, casting, joining, and finishing to create products from raw materials. Understanding these processes is essential in the industry; additional methods include extrusion, stamping, deep drawing, and shearing. Heat treatment alters metal properties through...

Steelmaking is a complex process that transforms raw materials like iron ore, coal, and limestone into high-quality steel through stages such as blast furnace melting, refining in Basic Oxygen or Electric Arc Furnaces, alloying, casting, forming, and finishing. Quality control...

Steel tech products are essential to modern infrastructure, offering enhanced strength, durability, and adaptability across various industries. They contribute to economic growth and sustainability through innovative manufacturing techniques that improve performance while reducing environmental impact....

Stainless steel manufacturing is a precise, multi-stage process combining advanced technology and strict quality control to produce durable, corrosion-resistant materials....