Ventilation

Ventilation

Einführung in die Ventilation

Die Ventilation spielt eine entscheidende Rolle in der Stahlproduktion und im Stahlhandel. Sie ist die Technik, die dabei hilft, die Luftqualität in den Industrieanlagen zu steuern und zu verbessern. Ventilation ist notwendig, um eine sichere und gesunde Arbeitsumgebung für die Arbeiter zu gewährleisten.

Warum ist Ventilation wichtig?

Ventilation ist wichtig, weil sie dazu beiträgt, jegliche schädliche Substanzen aus den Anlagen zu entfernen. Dies umfasst Dämpfe, Rauch, Staub und andere Arten von Schadstoffen, die während der Stahlproduktion entstehen können. Eine effektive Ventilation sorgt dafür, dass die Arbeiter nicht diesen gesundheitsschädlichen Substanzen ausgesetzt sind.

Ventilation in der Stahlproduktion und im Stahlhandel

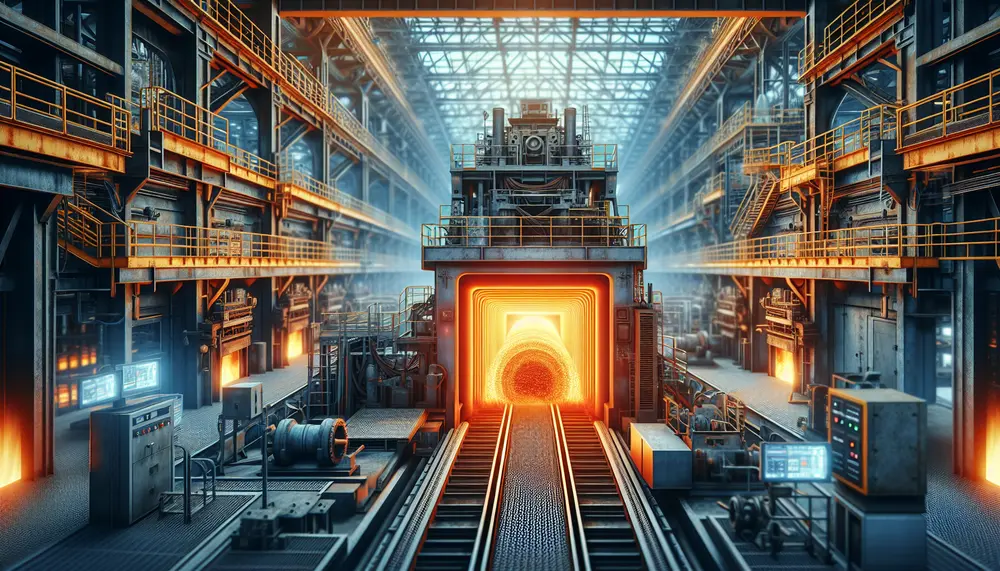

In der Stahlproduktion und im Stahlhandel muss die Ventilation besonders effektiv sein. Da der Stahlproduktionsprozess bei extrem hohen Temperaturen stattfindet, ist es wichtig, dass die Hitze und Dämpfe sicher aus der Anlage abgeleitet werden. Wenn dies nicht effektiv geschieht, kann dies zu gefährlichen Arbeitsbedingungen und sogar zu Schäden an der Ausrüstung führen.

Arten der Ventilation

Es gibt unterschiedliche Arten der Ventilation, die in der Stahlindustrie Anwendung finden. Die Hauptarten sind die mechanische und die natürliche Ventilation. Mechanische Ventilation beinhaltet den Einsatz von Geräten wie Ventilatoren und Absaugsystemen, um die Luft zu bewegen. Natürliche Ventilation hingegen bezieht sich auf Prozesse, die auf natürlichen Luftbewegungen basieren, wie zum Beispiel den Wind.

Schlussfolgerung

Ventilation in der Stahlproduktion und im Stahlhandel ist immens wichtig. Sie trägt zur Sicherheit am Arbeitsplatz bei und hilft, die Qualität und Leistung der Ausrüstung zu erhalten. Zugleich unterstützt sie die Einhaltung von Umweltauflagen, indem sie dafür sorgt, dass schädliche Substanzen effektiv beseitigt werden.

Blog Posts with the term: Ventilation

The steel industry is essential but poses significant risks to workers, including physical dangers from heavy machinery and extreme heat, chemical hazards from toxic substances, burn threats due to high temperatures in furnaces, and noise pollution leading to potential hearing...

Induction furnaces have transformed steel making with their efficiency, versatility, and reduced environmental impact compared to traditional fossil fuel-based furnaces. They use electromagnetic induction for heating metals precisely and quickly, offering benefits like energy savings, improved productivity, metallurgical control, scalability,...

Steel making transforms iron ore into steel using blast furnaces or electric arc furnaces, involving processes like smelting and carbon adjustment to achieve desired properties. The production includes primary methods like Basic Oxygen Steelmaking and Electric Arc Furnace, followed by...

Steel production transforms raw materials like iron ore, coal, and limestone into steel through high-temperature processes in a factory. This complex journey from earth-bound elements to the final product is essential for construction and manufacturing industries, with each material playing...

Steel fabrication involves transforming raw steel into structures or products using various techniques like cutting, bending, and joining to ensure strength and quality. Material selection is critical in this process as it affects the performance and longevity of the final...

Modern Damascus steel combines layered, contrasting steels and precise forging to create blades that are both visually striking and technically superior. Success relies on careful material selection, temperature control, pattern engineering, safety measures, and attention to detail at every step....

The steel production casting process involves melting raw materials, refining the molten metal, and pouring it into molds to shape solid products with controlled cooling to prevent defects. The variety of cast steels is determined by carbon content and alloying...

Steel products manufacturing transforms raw materials into essential items for modern life, involving a process from conceptualization to final product creation. The steel making process is an intricate journey that includes extraction of iron ore, refining in blast furnaces or...

HBI, or Hot Briquetted Iron, is a high-density and stable raw material that enhances steel quality while reducing carbon emissions and operational costs in modern steelmaking....

Steel manufacturing transforms iron ore into steel through a series of processes, starting with smelting in blast furnaces and including primary and secondary steelmaking to adjust chemical composition and remove impurities. The final product is cast, formed, and carefully temperature-controlled...

The article emphasizes the critical importance of maintaining safe working conditions in the steelmaking industry, highlighting how safety measures not only protect workers from various health risks like respiratory issues and hearing loss but also enhance overall productivity and company...

IspatGuru is a comprehensive resource for understanding steelmaking, offering insights into foundational concepts, advanced technologies like BOF and EAF processes, and sustainability. It bridges theory with practical applications while addressing modern challenges such as efficiency, environmental impact, and innovation in...

The Steele Products generator is essential for ensuring uninterrupted power supply during outages, with a 12,000 Watt output suitable for homes and businesses. It offers convenience through an electric start, durability, multiple outlets, noise reduction features, EPA approval, and ease...

Hydrogen is revolutionizing steel production by serving as a cleaner reducing agent, enabling the industry to reduce carbon emissions and align with sustainability goals. However, integrating hydrogen technology faces challenges such as infrastructure overhaul, storage and transportation logistics, economic factors,...