Posts on the Topic Automation

The KOBM steelmaking process, known for its combined oxygen blowing technique, enhances efficiency and quality by offering precise control over chemical composition, flexibility in producing various steel grades, reduced environmental impact, and cost-effectiveness compared to traditional methods....

The US steel industry has evolved from traditional methods to sustainable practices, focusing on recycling and technological innovation, with key players like Cleveland-Cliffs and Nucor leading advancements. Despite challenges such as international competition and environmental regulations, the industry remains a...

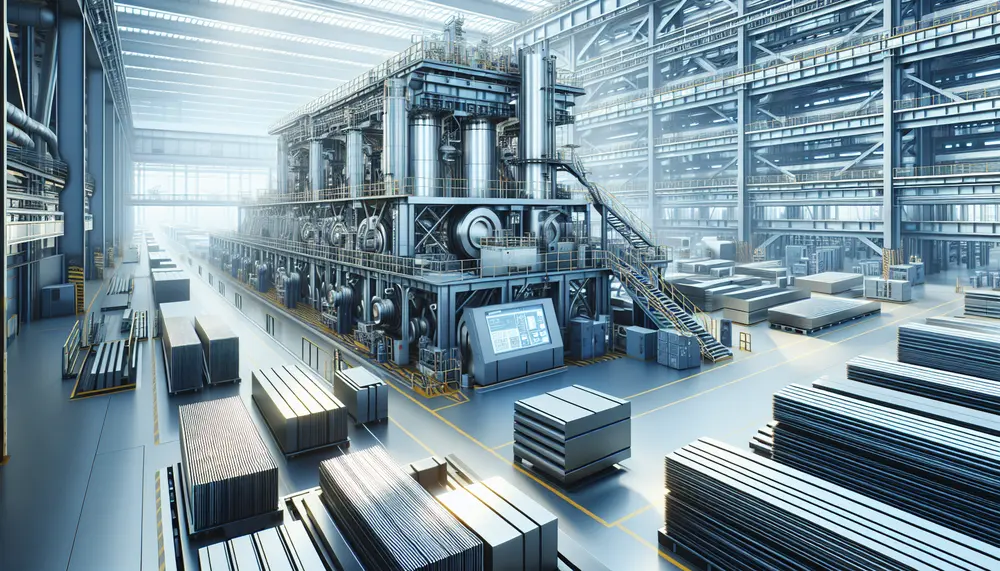

Direct Reduced Iron (DRI), crucial for sustainable steelmaking, offers an eco-friendlier alternative to traditional methods by using natural gas or hydrogen, reducing CO2 emissions and enhancing steel quality. Steel production has evolved significantly from the Bessemer process to modern techniques...

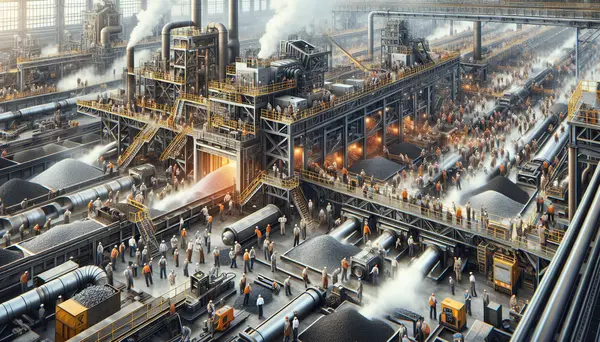

Steelmaking equipment is essential for transforming iron ore into steel, involving complex machines like furnaces and continuous casting machines that handle everything from melting to shaping. Technological advancements in this equipment have greatly improved efficiency, quality control, and environmental sustainability...

Advanced machinery has revolutionized steel production by increasing precision, speed, and control in processes like melting and shaping metals. Automation and digital controls have improved safety, quality consistency, and operational efficiency through data analysis. The evolution of steel production machinery from...

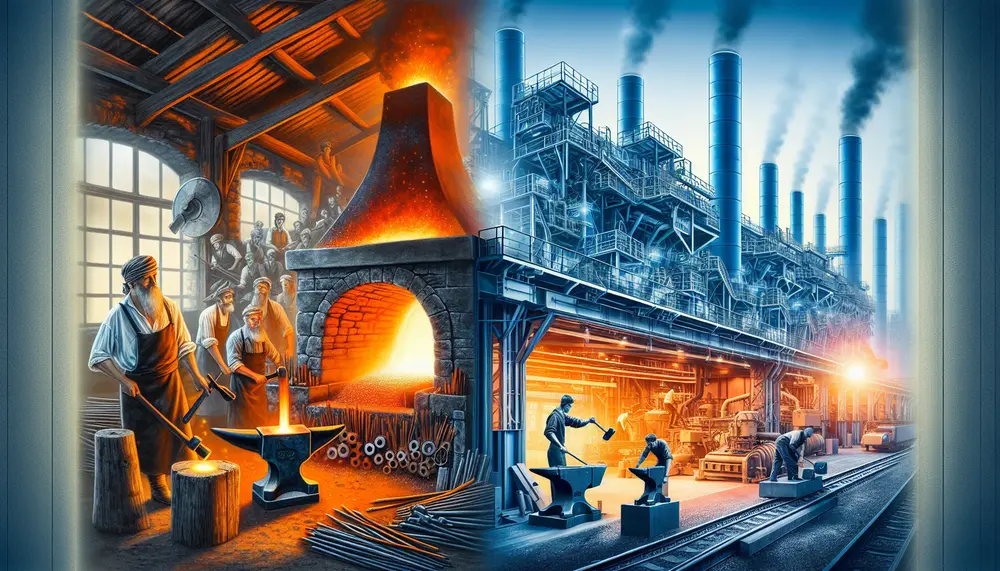

Steel production has evolved from the labor-intensive Open Hearth Process to the efficient Basic Oxygen Steelmaking and Electric Arc Furnaces, reflecting a century of technological advancements that have increased sustainability and reduced environmental impact. These innovations have transformed steelmaking into...

Steel production technology has evolved significantly, with the industry now using advanced methods like blast furnaces and electric arc furnaces to meet global demands. Technological improvements have enhanced quality, efficiency, and sustainability in steel making. The future of steel production focuses...