Posts on the Topic Degassing

Vacuum Tank Degassing (VTD) revolutionizes steelmaking by delivering ultra-pure, high-performance steels with superior mechanical properties and process flexibility. Its adoption drives innovation across industries like automotive, energy, and medical devices while digital monitoring boosts efficiency and traceability....

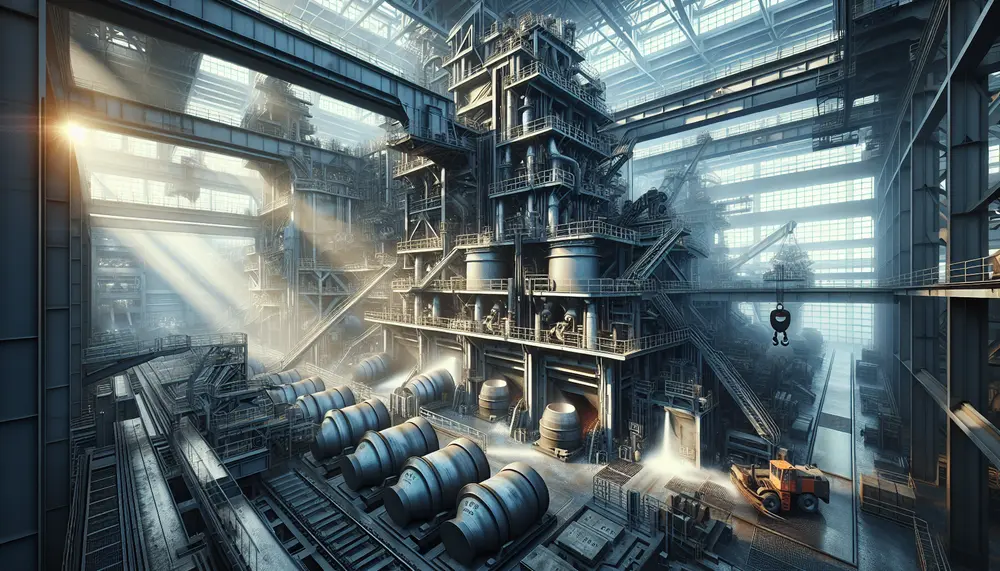

Secondary steelmaking refines and adjusts the composition of steel to meet specific standards, involving processes like deoxidation, desulfurization, decarburization, alloying, and degassing. It is crucial for producing high-quality steel with desired properties such as strength and corrosion resistance. The role of...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...