Posts on the Topic Impurities

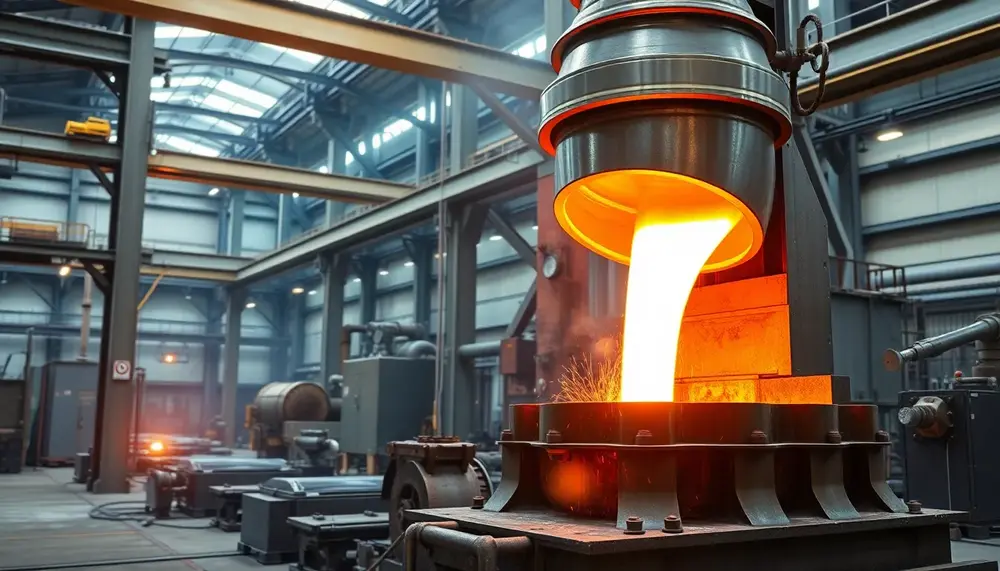

Secondary steelmaking refines and customizes steel after primary production, enabling precise control over composition and purity to meet modern industry demands. Key stages include deslagging, alloy addition, temperature adjustment, degassing, inclusion modification, and homogenization using advanced technologies like ladle furnaces...

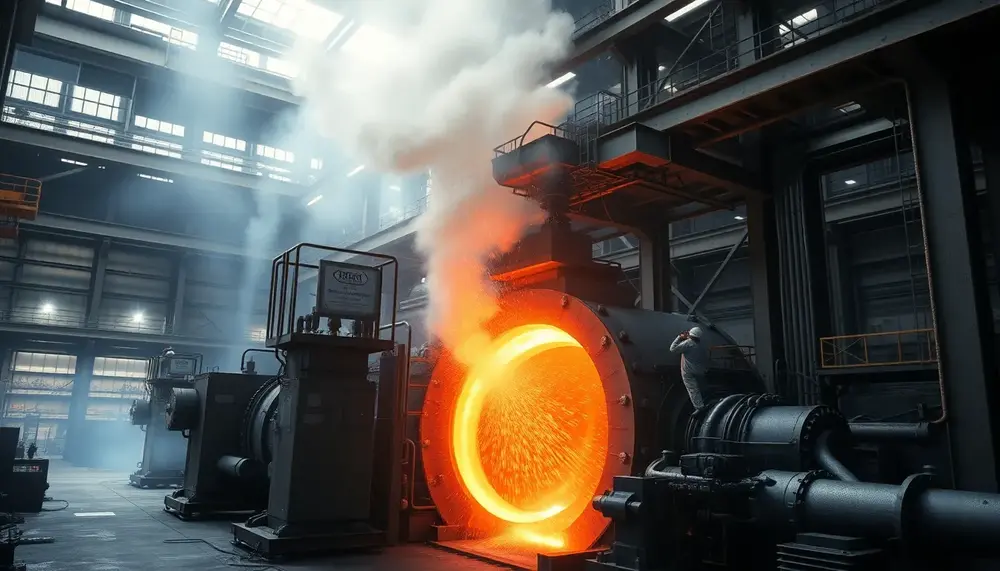

Converters are the core of modern steelmaking, rapidly transforming raw iron into high-quality steel through precise oxygen blowing and advanced process control. Their evolution—from Bessemer’s air-blown vessel to today’s digitally monitored systems—enables flexible, efficient production that meets diverse industrial demands....

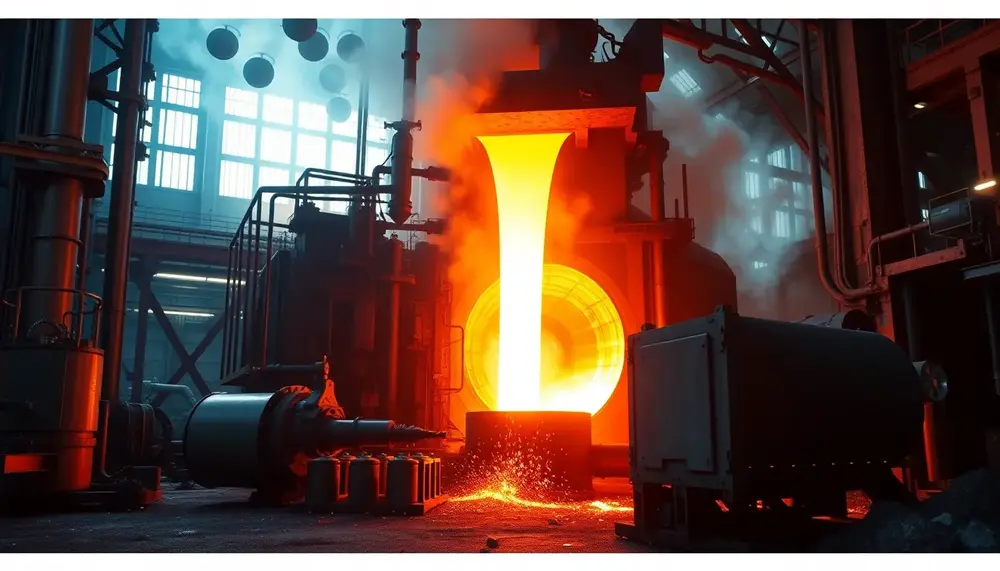

Vacuum Induction Melting (VIM) revolutionizes steel-making by enabling ultra-pure alloys through precise melting, impurity removal in a vacuum, and real-time composition control. Recent innovations like advanced monitoring systems, hybrid techniques, and energy-efficient designs enhance material quality while promoting sustainability for...

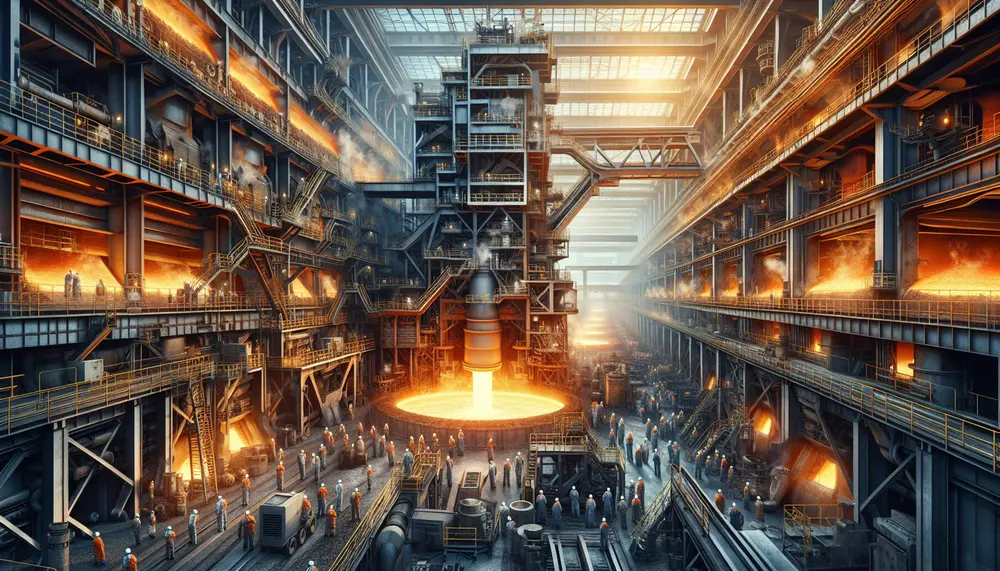

The art of medieval steelmaking combined intuition, tradition, and a deep understanding of metallurgy to create strong yet flexible materials essential for tools, weapons, and status symbols. Despite limited scientific knowledge and resources, artisans mastered techniques like carbon infusion and...

Steel refining transforms raw materials into high-quality steel by removing impurities and enhancing properties through advanced techniques like BOF, EAF, and DRI. Modern innovations ensure precision, efficiency, sustainability, and tailored applications across industries while addressing environmental challenges....

Henry Bessemer revolutionized steel production in the 19th century with his innovative process, enabling mass production of stronger, affordable steel and fueling industrial growth. By efficiently removing impurities through oxygen blasts, his method drastically reduced costs and transformed steel into...

Steelmaking combines science and engineering to transform raw materials into tailored steel products through precise control of temperature, composition, and reactions. Its evolution reflects human innovation, from ancient smelting techniques to modern sustainable methods driven by advanced theoretical principles like...

The reduction ratio in steel making is crucial for optimizing efficiency, cost-effectiveness, and quality by determining the mechanical properties of steel through factors like temperature and impurities. Modern advancements have shifted from traditional ratios to more efficient ones, reflecting innovation...

The oxygen steelmaking process revolutionized the industry by efficiently producing high-quality steel through pure oxygen blowing, significantly reducing production time and costs. Key components include a converter, an oxygen lance for impurity removal, refractory lining protection, and slag formation to...

Desulfurization in steelmaking is crucial for producing high-quality, durable steel by removing sulfur impurities that cause brittleness; advancements and techniques like desulfurizing agents, slag optimization, and vacuum treatment enhance this process while addressing challenges such as cost and environmental concerns....

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...