Posts on the Topic Materials

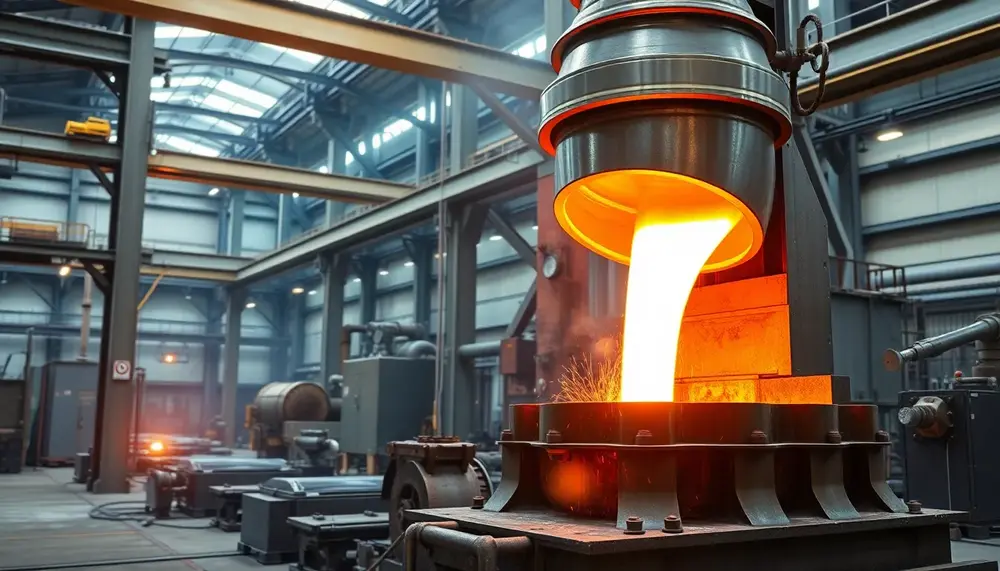

Vacuum Induction Melting (VIM) revolutionizes steel-making by enabling ultra-pure alloys through precise melting, impurity removal in a vacuum, and real-time composition control. Recent innovations like advanced monitoring systems, hybrid techniques, and energy-efficient designs enhance material quality while promoting sustainability for...

The article highlights the growing demand for steelmaking faculty roles, emphasizing their critical contributions to sustainability, innovation, and industry-academia collaboration. Faculty members drive research, mentor future leaders, shape curricula, and foster partnerships to advance sustainable practices and technological progress in...

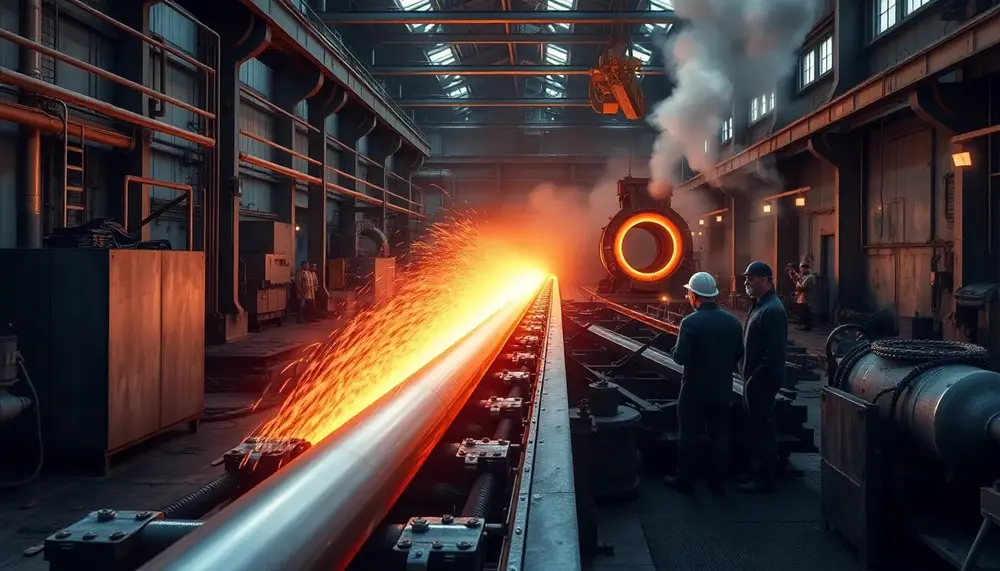

The transformation of steel production, marked by innovations like the Bessemer Process and later advancements, revolutionized industries by enabling faster, cheaper, and higher-quality steel manufacturing. These breakthroughs fueled industrial growth, urbanization, modern infrastructure development, and laid the foundation for a...

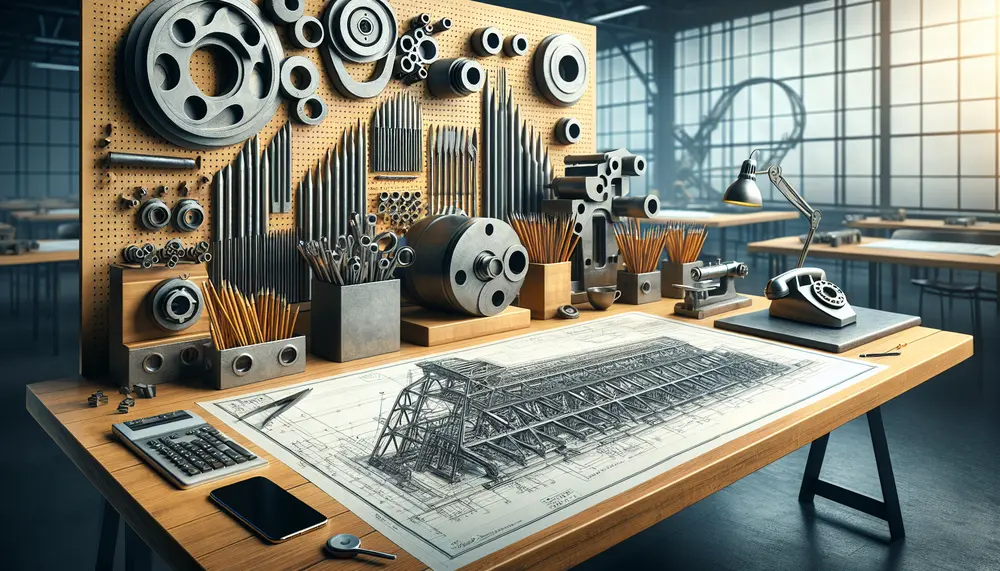

The article emphasizes the importance of visually presenting the steel manufacturing process through engaging PowerPoint slides, breaking down complex steps like raw material preparation and blast furnace operations using diagrams, animations, and concise text to enhance understanding for diverse audiences....

Steelmaking R&D drives innovation by integrating sustainability, advanced technologies like hydrogen-based processes and AI modeling, and fostering breakthroughs in efficiency and emissions reduction. These advancements are reshaping industries reliant on steel while addressing global environmental challenges through cleaner production methods...

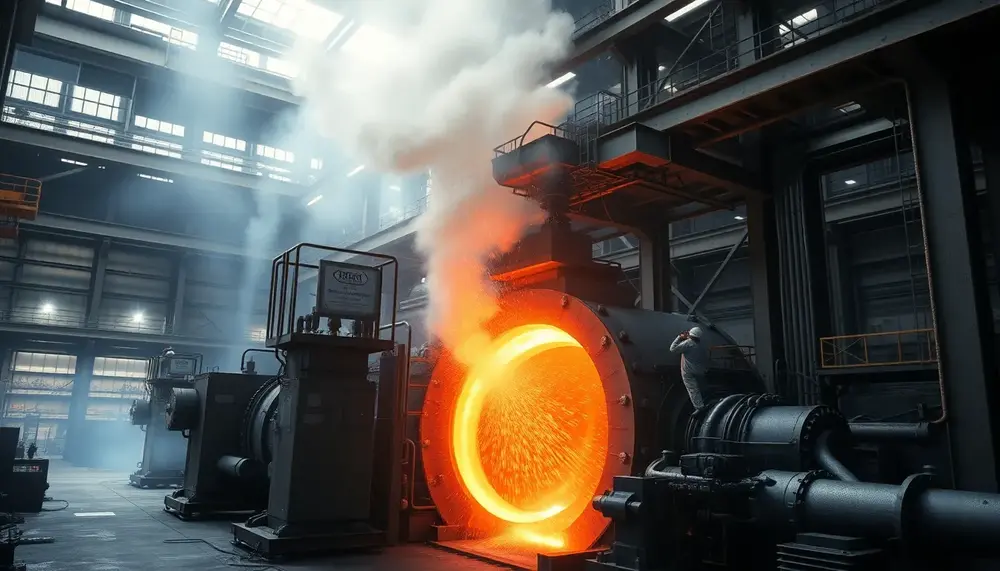

The article explores global steel production, focusing on the Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF) methods, highlighting their processes, environmental impacts, and adaptability. It emphasizes how sustainability trends are reshaping these techniques while secondary steelmaking refines quality...

Steel manufacturing transforms raw materials like iron ore into robust steel products through a complex process involving chemistry, physics, and engineering. This journey from ancient methods to modern techniques includes steps such as blast furnace operations and refining processes, highlighting...

Understanding global steelmaking capacity is essential for industry stakeholders as it influences market dynamics, economic stability, and trade relations. Factors such as technological advancements, economic conditions, government policies, raw material availability, market demand, and global trade dynamics impact this capacity;...

Steel making refractory materials are essential for lining furnaces and equipment in steel production, with various types like fireclay, high alumina, silica, magnesite, and chromite refractories tailored to specific conditions. These materials ensure heat containment, protect equipment from damage, maintain...

Steelmaking drawings are essential blueprints that ensure precision, coordination, cost control, time management, and quality assurance in steel production. Advanced tools like CAD and techniques such as FEA and BIM enhance the creation process by improving accuracy, efficiency, and collaboration...

Steelmaking universities offer a blend of theoretical and practical education in metallurgical engineering, focusing on the science behind metal properties and production processes. Students learn through courses ranging from thermodynamics to advanced materials engineering, with hands-on experience in modern labs...

The steel industry is adapting to current market trends, including geopolitical tensions and technological disruptions, while moving towards sustainable practices. Global events like the Ukraine conflict and COVID-19 pandemic have impacted supply chains and trade flows, with innovations in manufacturing...