Posts on the Topic Ore

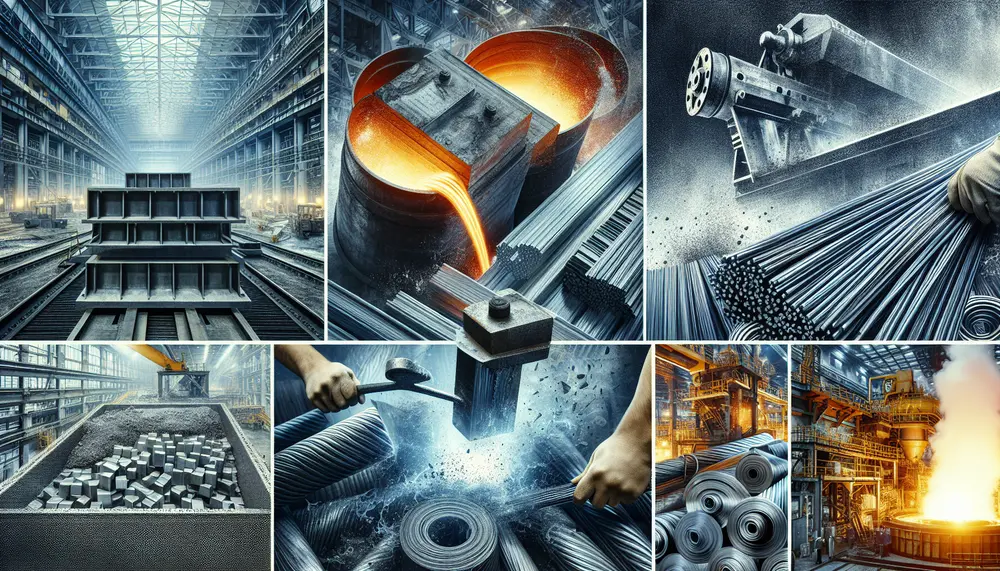

Steelmaking equipment is essential for transforming iron ore into steel, involving complex machines like furnaces and continuous casting machines that handle everything from melting to shaping. Technological advancements in this equipment have greatly improved efficiency, quality control, and environmental sustainability...

Hydrogen is revolutionizing steel production by serving as a cleaner reducing agent, enabling the industry to reduce carbon emissions and align with sustainability goals. However, integrating hydrogen technology faces challenges such as infrastructure overhaul, storage and transportation logistics, economic factors,...

Steelmaking, particularly through traditional blast furnace methods, significantly contributes to environmental degradation by emitting greenhouse gases like CO2 and other pollutants. Transitioning to greener technologies such as Electric Arc Furnaces (EAF) could reduce these emissions but requires substantial investment and...

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...

ArcelorMittal's steel making process combines traditional methods with advanced technologies, focusing on sustainability and efficiency. The company continuously innovates to improve quality and reduce environmental impact while maintaining a strategic approach to resource management in the global steel industry....

Steel products are essential due to their strength, durability, and adaptability across various industries; innovations in steel technology continue to expand its applications and sustainability. The material's journey from raw ore to diverse uses demonstrates its versatility, while advancements like...