Posts on the Topic Slag

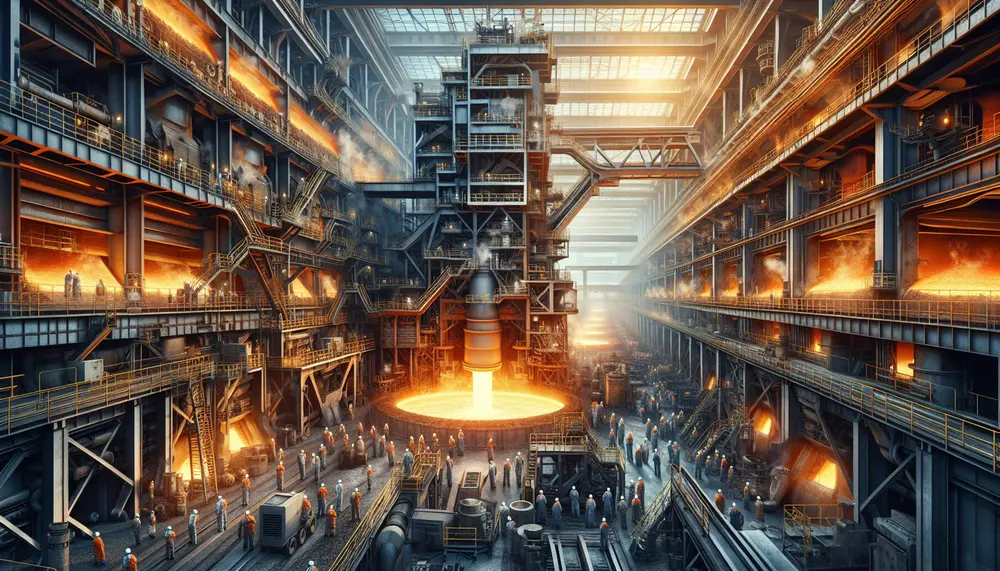

Steel production faces major environmental challenges, including high CO2 emissions, water and air pollution, waste management issues, and resource depletion. Innovative solutions like hydrogen-based processes and closed-loop water systems are emerging to reduce the industry's ecological footprint....

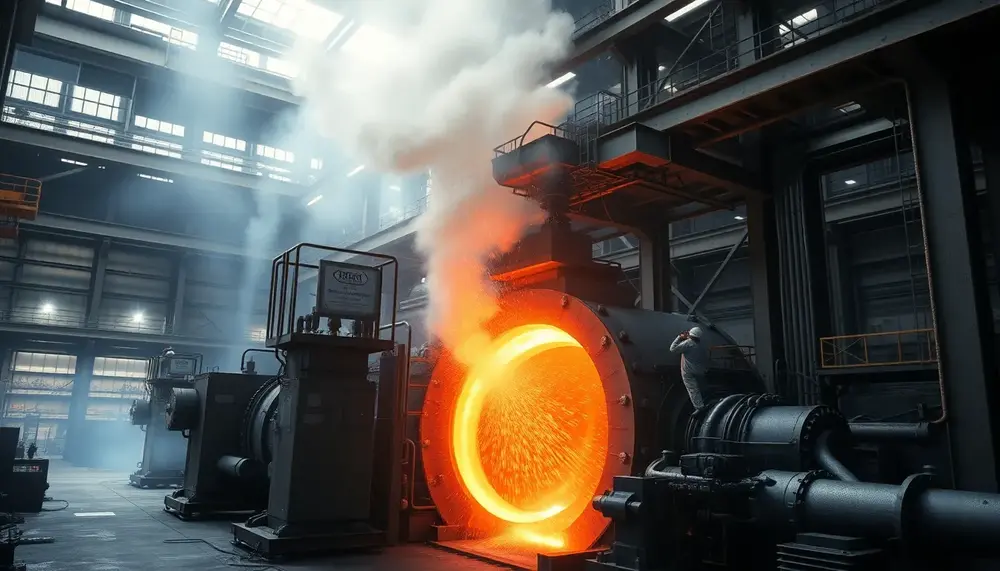

Converters are the core of modern steelmaking, rapidly transforming raw iron into high-quality steel through precise oxygen blowing and advanced process control. Their evolution—from Bessemer’s air-blown vessel to today’s digitally monitored systems—enables flexible, efficient production that meets diverse industrial demands....

IspatGuru is a comprehensive resource for understanding steelmaking, offering insights into foundational concepts, advanced technologies like BOF and EAF processes, and sustainability. It bridges theory with practical applications while addressing modern challenges such as efficiency, environmental impact, and innovation in...

The oxygen steelmaking process revolutionized the industry by efficiently producing high-quality steel through pure oxygen blowing, significantly reducing production time and costs. Key components include a converter, an oxygen lance for impurity removal, refractory lining protection, and slag formation to...

Desulfurization in steelmaking is crucial for producing high-quality, durable steel by removing sulfur impurities that cause brittleness; advancements and techniques like desulfurizing agents, slag optimization, and vacuum treatment enhance this process while addressing challenges such as cost and environmental concerns....

Steel making refractory materials are essential for lining furnaces and equipment in steel production, with various types like fireclay, high alumina, silica, magnesite, and chromite refractories tailored to specific conditions. These materials ensure heat containment, protect equipment from damage, maintain...

The Argon Oxygen Decarburization (AOD) process is essential in producing high-quality stainless steel by refining molten steel to reduce carbon content while preserving valuable alloying elements like chromium. This method, involving precise control of gas mixtures and temperatures during decarburization,...

Steelmaking waste, primarily consisting of slag, dust, and sludges from iron and steel production processes, poses significant environmental risks such as groundwater contamination and ecosystem degradation if not managed properly. However, innovative recycling techniques like using slag in concrete or...