Posts on the Topic Technology

Steel decarbonization is driven by market, policy, and investor pressure but faces major challenges from legacy infrastructure, high costs, raw material limits, and uncertain regulations. Hydrogen-based steelmaking and electric arc furnaces offer promising low-carbon solutions if supply chains and renewable...

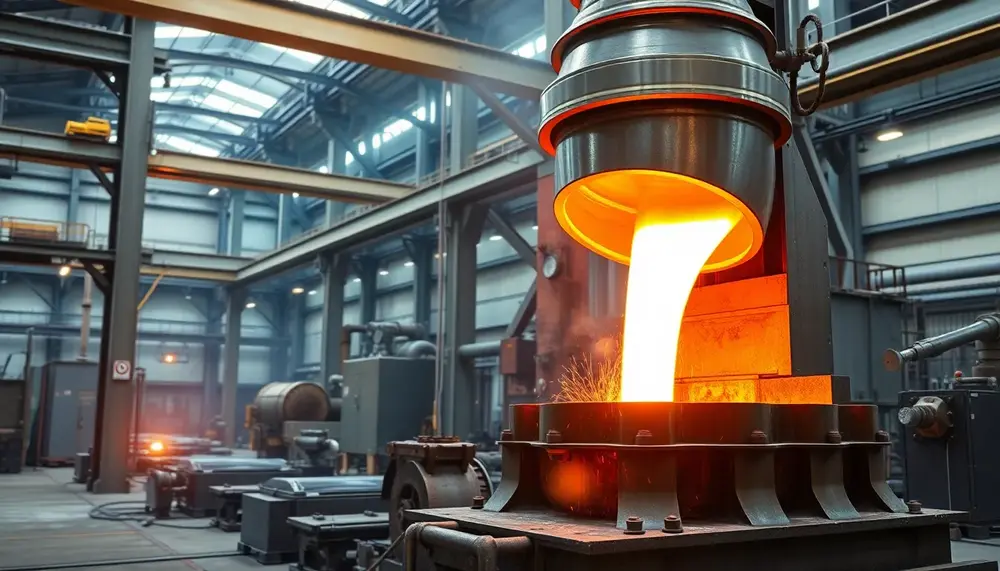

Vacuum Induction Melting (VIM) revolutionizes steel-making by enabling ultra-pure alloys through precise melting, impurity removal in a vacuum, and real-time composition control. Recent innovations like advanced monitoring systems, hybrid techniques, and energy-efficient designs enhance material quality while promoting sustainability for...

IspatGuru is a comprehensive resource for understanding steelmaking, offering insights into foundational concepts, advanced technologies like BOF and EAF processes, and sustainability. It bridges theory with practical applications while addressing modern challenges such as efficiency, environmental impact, and innovation in...

The transformation of steel production, marked by innovations like the Bessemer Process and later advancements, revolutionized industries by enabling faster, cheaper, and higher-quality steel manufacturing. These breakthroughs fueled industrial growth, urbanization, modern infrastructure development, and laid the foundation for a...

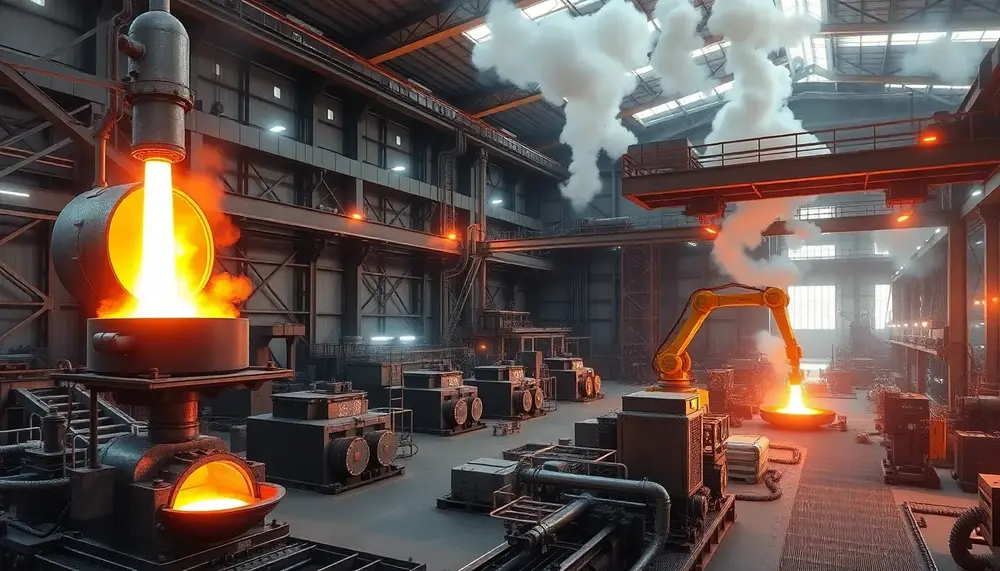

Steel refining transforms raw materials into high-quality steel by removing impurities and enhancing properties through advanced techniques like BOF, EAF, and DRI. Modern innovations ensure precision, efficiency, sustainability, and tailored applications across industries while addressing environmental challenges....

The evolution of steelmaking in America reflects centuries of innovation, from colonial ironworks to modern high-tech factories, driven by technological breakthroughs and economic demands. Key milestones like the Bessemer process and basic oxygen furnaces revolutionized production efficiency, solidifying steel's role...

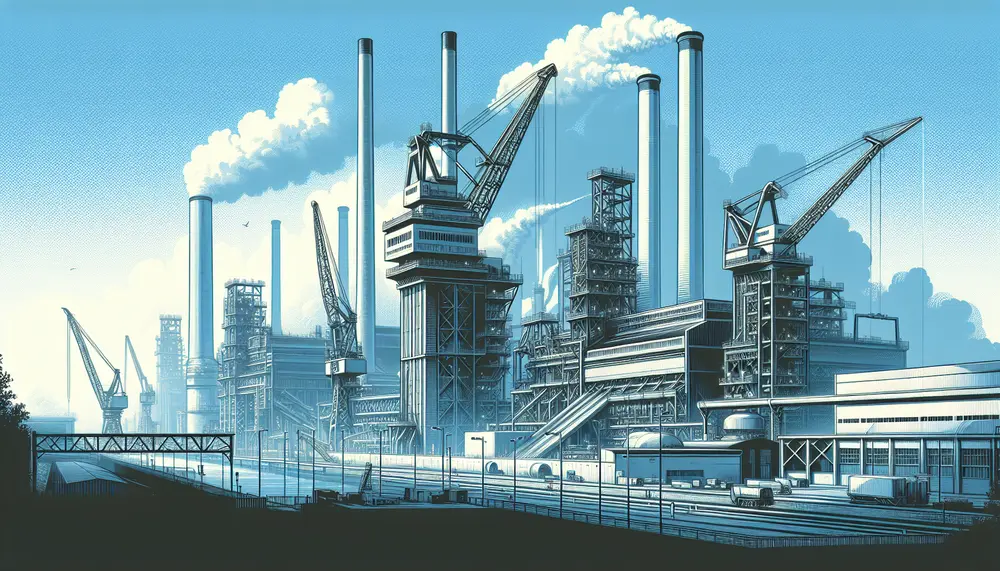

The article provides a detailed overview of the steelmaking process, highlighting key components like raw materials, energy sources, and advanced technologies. It explains primary methods (BOF and EAF), step-by-step production stages, and emphasizes sustainability and innovation in modern steel manufacturing....

The article highlights the importance of influential names in steelmaking, emphasizing their role in driving innovation and shaping industry policies for sustainability. Key players like AISI advocate for pro-manufacturing policies, infrastructure development, and environmental practices while modern technologies such as...

Steelmaking R&D drives innovation by integrating sustainability, advanced technologies like hydrogen-based processes and AI modeling, and fostering breakthroughs in efficiency and emissions reduction. These advancements are reshaping industries reliant on steel while addressing global environmental challenges through cleaner production methods...

The KOBM steelmaking process, known for its combined oxygen blowing technique, enhances efficiency and quality by offering precise control over chemical composition, flexibility in producing various steel grades, reduced environmental impact, and cost-effectiveness compared to traditional methods....

The article analyzes global steel production trends in 2023, highlighting regional differences and challenges such as supply chain disruptions. It examines the contrasting growth patterns across continents like Africa's rise due to infrastructure investments and Asia's decline influenced by China's...

CFD steelmaking jobs are on the rise, offering a blend of technology and metallurgy to optimize processes in the steel industry through simulations that enhance efficiency and sustainability. Professionals in this field require technical proficiency, software expertise, analytical skills, problem-solving...

Steelmaking capacity is crucial for understanding the steel industry's dynamics, with factors like plant size and technology influencing production levels; the OECD plays a key role in monitoring global capacity, promoting sustainable practices, and addressing challenges such as overcapacity through...

Desulfurization in steelmaking is crucial for producing high-quality, durable steel by removing sulfur impurities that cause brittleness; advancements and techniques like desulfurizing agents, slag optimization, and vacuum treatment enhance this process while addressing challenges such as cost and environmental concerns....

Trading and logistics are essential in the steel industry, ensuring efficient movement of products from manufacturers to end-users. By optimizing these processes through best practices and technological innovations like automated warehousing, IoT, blockchain, advanced analytics, ERP systems, TMS solutions, WMS...