Table of Contents:

Understanding the Basics of Steel Products

Steel stands as a cornerstone material critical for a variety of industries, underpinning the development of modern society. At its core, steel is an alloy primarily composed of iron, with a carbon content that typically ranges between 0.2% and 2.14%. The distinct characteristics and mechanical properties of steel products are shaped by varying this carbon content and adding other elements such as manganese, chromium, vanadium, and tungsten.

One of the key attributes of steel is its versatility. This material is renowned for its strength and durability, making it an essential component in construction, automotive, and machinery manufacturing. What makes steel products so adaptable is their ability to be custom-tailored through controlled heat treatments and mechanical processing to meet specific performance requirements.

Furthermore, steel's recyclability contributes significantly to its sustainability profile. Steel products can be melted down and re-forged numerous times without losing their quality, making them a preferable choice in eco-conscious applications. This enduring lifecycle not only conserves resources but also minimizes waste.

A firm grasp of these fundamental qualities helps one appreciate the inherent potential locked within steel products, serving as the very backbone of our built environment and supporting a range of industries with reliable and sturdy materials.

The Importance of Steel in Modern Industry

The role of steel extends far beyond its material properties, influencing economic growth and technological advancement. Modern industry leans heavily on steel products for their structural integrity and cost-effectiveness, which is particularly evident in sectors such as construction, transportation, energy, and infrastructure. Steel is pivotal in constructing skyscrapers, bridges, railways, and ships that form the backbone of global commerce.

In addition to structural uses, steel products are instrumental in the manufacturing of machinery and tools. Their ability to withstand high stress and temperature variations enables the production of equipment that maintains performance under demanding conditions. From the automotive industry to aerospace, steel-based components are integral in both everyday vehicles and advanced aircraft.

The medical field also benefits from specialised steel products. Surgical instruments and medical devices utilise stainless steel for its hygienic qualities and resistance to corrosion, which is critical for patient safety and successful outcomes. The adaptability of steel products ensures they meet the rigorous standards required in healthcare settings.

Moreover, with the increasing focus on renewable energy, steel products are crucial in the construction of wind turbines and solar panels, supporting the shift towards more sustainable energy sources. The strength and resilience of steel fortify these structures against harsh environmental conditions, ensuring longevity and consistent energy production.

Consequently, steel's impact on modern industry is vast and multifaceted. Its enduring presence across various sectors illustrates the indispensable role it plays in driving progress and building a resilient industrial landscape.

Assessing the Benefits and Drawbacks of Steel Usage

| Pros of Steel Products | Cons of Steel Products |

|---|---|

| High strength-to-weight ratio | Corrosion can be an issue without proper treatment |

| Durable and long-lasting | Higher initial cost compared to some other materials |

| Recyclable and eco-friendly | Requires energy-intensive production processes |

| Versatile in application | Can be heavy, increasing transportation costs |

| Prefabrication capabilities for quick assembly | Subject to price fluctuations due to market demand |

Types of Steel Products and Their Uses

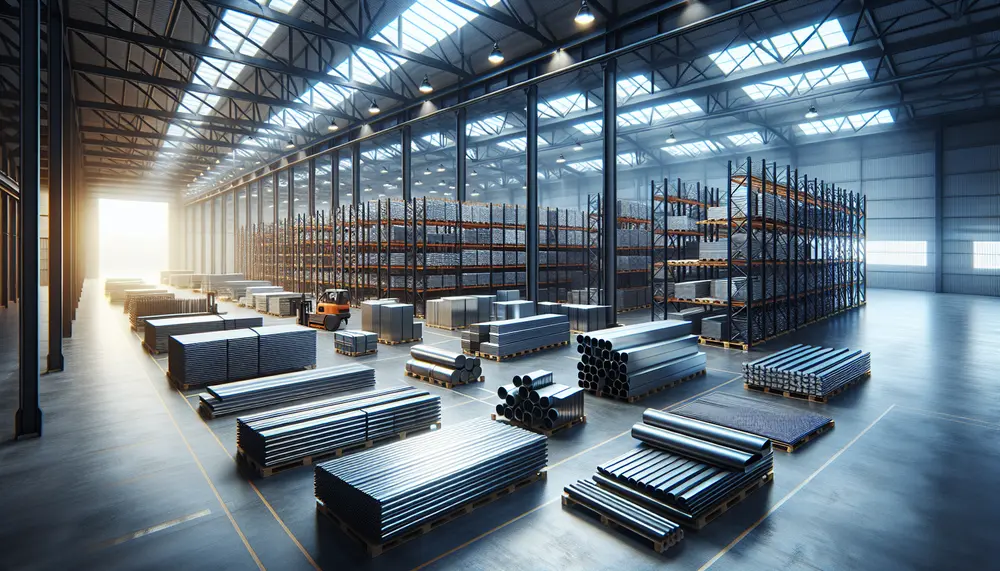

Steel products come in a myriad of forms, each catering to specific industrial needs. From the hefty I-beams used in heavy construction to the precision-cut gears in machinery, the range of steel products is as diverse as the applications they serve.

- Flat Products: These include sheets and plates that are used in automobiles, ships, and for making large pipes. Also, they find application in domestic appliances and in construction as part of roofing, cladding, and framing.

- Long Products: These are typically shaped as beams, railway tracks, and rods. Long steel products are crucial in construction for structural support and foundations, as well as in the manufacturing of tools and other hardware.

- Tubular Products: These encompass various pipes and tubes used extensively in the oil and gas industry, as well as in construction for structural purposes and in conveying fluids.

- Stainless Steel Products: Known for their corrosion resistance, these are used in environments where rust or chemical corrosion can be a problem. Applications include kitchen appliances, medical instruments, and cutlery.

- Special Steel Products: Developed for particular applications, special steel products include tool steel for cutting and drilling equipment, and silicon steel used primarily in electrical transformers.

Each type of steel product is engineered to provide certain characteristics such as increased strength, flexibility, corrosion resistance, or electrical conductivity. These attributes are precisely calibrated depending on the application, ensuring that the chosen steel product is fit for its intended use.

The Steel Production Process Explained

The production of steel is a complex and multi-step process that transforms raw materials into the steel products that are foundational to various industries. The journey from raw iron ore to finished steel goods entails several crucial stages:

- Raw Material Extraction: The process begins with the extraction of iron ore, limestone, and coal, which are the primary raw materials needed to produce steel.

- Ironmaking: The raw materials are converted to iron through a blast furnace that melts the iron ore in the presence of coke—a carbon-rich form of coal—and limestone. This step produces molten iron, also known as pig iron, and a byproduct called slag.

- Steelmaking: The pig iron is then transferred to a steel-making furnace. Here, processes like basic oxygen steelmaking (BOS) or electric arc furnace (EAF) methods purify the iron by removing excess carbon and other impurities. The molten steel is further refined to achieve the desired chemical composition and properties.

- Secondary Steelmaking: Following the primary steelmaking process, secondary refining techniques are applied to fine-tune the composition of the steel. Procedures such as ladle furnace refining and vacuum degassing are utilized to enhance the quality of the steel.

- Casting: The refined molten steel is then cast into various shapes, such as slabs, billets, or blooms, through continuous casting or ingot casting methods. This solidified steel is the starting material for further manufacturing.

- Forming and Shaping: These steel forms are processed into finished products using a variety of techniques, including rolling (for sheets, plates, and long products), forging, extruding, or drawing (for wires and pipes).

- Heat Treatment: To achieve the required mechanical properties, steel products may be subjected to various heat treatments such as quenching, tempering, or annealing.

- Finishing: The final step involves finishing processes like coating, painting, or galvanizing, which provide protection against corrosion and give steel products their final aesthetic and functional qualities.

This sequence of steps ensures that the steel's inherent strength and versatile properties are harnessed to produce materials suitable for a myriad of applications, solidifying steel's role as an integral material in modern manufacturing and construction.

Innovations in Steel: Enhancing Quality and Durability

Steel continues to push the boundaries of performance through ongoing innovation. Researchers and engineers are dedicated to developing new steel products and enhancing the quality and durability of existing ones, leading to breakthroughs that have substantial implications for a multitude of industries.

Advancements in **material science** have led to the creation of **high-strength, low-alloy (HSLA) steels**. These steels boast improved strength-to-weight ratios, making them ideal for automotive applications where they contribute to fuel efficiency by reducing overall vehicle weight without compromising safety or performance.

Moreover, the steel industry has made significant strides in creating **weathering steels**. These are uniquely formulated to develop a protective rust patina that shields the structural integrity of the material from corrosion, thereby eliminating the need for paint or other surface treatments in certain environments.

Another innovation in the pursuit of durability is the development of **coated steel products**. Techniques such as **galvanization**, where steel is coated with a protective layer of zinc, protect the material from oxidation and corrosion. Advanced coating methods, such as using aluminum-zinc alloys, provide even longer-lasting protection, especially in harsh climate conditions.

With the rise of sustainable building practices, the steel industry has responded with the production of **energy-efficient steel grades** that help in reducing greenhouse gas emissions during production. Melting and reforming processes are optimized to minimize energy consumption and environmental impact.

Innovation extends to the realm of manufacturing, with processes like 3D printing of steel opening new possibilities for complex structures and components that were previously challenging or impossible to produce with traditional methods. This not only allows for greater design freedom but also contributes to more efficient material usage and reduced waste.

The continuous advancement in steel technology underscores the industry's commitment to providing materials that are not only stronger and more durable but also smarter and more environmentally responsible. These innovations ensure that steel remains a vital and evolving material, ready to meet the challenges of both today and tomorrow.

Steel Recycling: A Sustainable Approach

Steel recycling is a paramount aspect of the steel industry's efforts to enhance environmental sustainability and efficiency. This eco-friendly practice not only conserves natural resources but also reduces the carbon footprint associated with steel production.

Recycled steel maintains the metal's quality and can be used in the production of new steel products without any degradation in performance, making steel a truly cyclical resource. The sustainability of steel is further emphasized by the fact that it is one of the most recycled materials in the world.

Economically, steel recycling provides cost savings as it requires significantly less energy than producing steel from virgin materials, thereby reducing overall production costs. Additionally, the recycling process minimizes the need for landfill space, which is beneficial for both the environment and communities.

The industry utilizes scrap steel as the primary input for electric arc furnace (EAF) technology, a method that can produce high-quality steel with up to 100% recycled content. The versatility of steel recycling allows for a wide range of applications, from construction beams to automotive parts and packaging materials.

Steel industry stakeholders, from governments to private entities, have invested in collection networks and processing facilities that bolster the ease and efficiency of steel recycling. As a result, the life cycle of steel has been effectively extended, contributing to a more sustainable industry and a greener planet.

Challenges and Solutions in Steel Manufacturing

While steel manufacturing is a vital industry globally, it faces a host of challenges, ranging from environmental impact to technological and economic hurdles. Addressing these issues is key to ensuring the industry’s longevity and compatibility with a sustainable future.

One significant challenge is the **environmental impact** of steel production, particularly carbon emissions and energy consumption. To combat this, manufacturers are implementing **cleaner and more efficient production methods**, such as using electric arc furnaces, which are more energy-efficient than traditional blast furnaces. Additionally, there is an increasing focus on **developing carbon capture and storage (CCS)** technologies to minimize greenhouse gas emissions from steel plants.

The rising cost of raw materials is another concern, leading to the need for **enhanced supply chain management**. Steel manufacturers are exploring alternative sources and materials, including **increased use of recycled steel**, which can reduce dependence on raw iron ore and coal while also cutting costs.

Technologically, the industry must continually adapt to keep pace with **innovations in material science**. Investments in research and development allow for the creation of **new steel alloys and composites** that cater to the ever-evolving demands of consumers and industries.

In response to global competition, steel manufacturers strive to **improve production efficiency and product quality**. This often involves adopting **advanced manufacturing technologies** like automation, robotics, and Industrial Internet of Things (IIoT), which enhance operational efficiency and reduce waste.

Regulatory compliance also poses challenges, particularly as governments worldwide enact stricter environmental and safety regulations. Steel companies are urged to adopt **best practices** in compliance management to adhere to these regulations without hampering their operational productivity.

Despite the complexity of these challenges, the steel industry's proactive approach in identifying and implementing sustainable and innovative solutions ensures its critical role in fueling the world's economy while moving towards greener and more eco-friendly manufacturing processes.

The Global Steel Trade: Trends and Insights

The global steel trade is a dynamic and influential market, with trends and patterns that reflect the economic health of nations and industries worldwide. It plays a critical role in international commerce, with evolving trade relationships shaping the flow of steel products across borders.

An observable trend is the **fluctuation in steel prices**, which is largely governed by supply and demand dynamics. Economic growth drives demand for steel in construction and manufacturing, while industry overcapacity or reduced economic activity can lead to an oversupply and falling prices.

Another trend is the **shift towards regional trade blocs** and bilateral agreements. Countries are forming strategic partnerships to secure steel trade, which has led to the emergence of localized supply chains. This shift helps in mitigating global trade disputes and tariff implementations that can disrupt the broader market.

The past few years have seen **China's influence** on the steel trade grow, as it remains the largest producer and consumer of steel. The country's economic policies, production levels, and export volumes have a substantial impact on the global steel trade landscape.

Trade policies, including **tariffs and quotas**, continue to affect the steel trade significantly. In response to such measures, some countries are investing in domestic steel production to reduce reliance on imports, which has implications for the global distribution of steel manufacturing hubs.

**Digitalization and technology** also play a role in shaping the steel trade. The adoption of blockchain, for instance, could streamline trade operations, making transactions more transparent and secure. Advancements in logistics and supply chain management software are enabling more efficient transport and delivery of steel products.

The steel trade is also increasingly influenced by **sustainability concerns**. As more businesses and consumers prioritize eco-friendly products, there is greater demand for steel made from recycled materials or produced with lower emissions. Steel producers who adapt to these environmental demands are likely to gain a competitive edge in the market.

Understanding these trends and insights is critical for stakeholders in the global steel trade, as they navigate through the complexities of international commerce, looking to strategically position themselves for long-term growth and success.

Future of Steel: Advancements and Predictions

The steel industry stands on the brink of a transformative era, where advancements in technology and shifts in global priorities forecast a future of both innovation and change. Anticipating these developments is vital for industry leadership and economic strategists alike.

One significant area of advancement is in **material science**, where ongoing research is producing **new steel alloys** with enhanced properties such as strength, flexibility, and resistance to wear and corrosion. These materials promise to revolutionize fields such as construction, automotive, and aerospace engineering.

Another emerging trend is the industry's adoption of **Industry 4.0 technologies**. Smart factories utilizing automation, AI, and advanced analytics are predicted to improve efficiency and reduce waste, leading to more sustainable production methods and a smaller environmental footprint.

In terms of sustainability, the integration of **renewable energy sources** in steel production is expected to mitigate the industry's carbon emissions. Companies are also likely to escalate the use of **electric arc furnace (EAF) technology**, which is not only cleaner but also more adaptable to recycling processes.

The incorporation of **digital technology** in the industry's operations is also anticipated. From supply chain logistics to customer engagement, digital platforms will increasingly streamline operations and foster more data-driven decision-making.

The global steel trade may see a greater focus on **circular economy principles**, with an emphasis on end-of-life product recovery, recycling, and material conservation. Such practices will not only align with global sustainability targets but also resonate positively with consumers.

Predictions also point towards more **localized production**, as a response to protectionist trade policies and the need for supply chain resilience. This shift could prompt new trade patterns and alter the geography of the steel industry.

Ultimately, the future of steel hinges on its ability to adapt and innovate. The industry is set to face new challenges but also seize unprecedented opportunities, shaping a path forward that is both sustainable and technologically advanced.

Conclusion: The Ever-Evolving World of Steel Products

In conclusion, the world of steel products is one of continuous evolution and innovation. As we have explored, the versatility and adaptability of steel have made it indispensable in a myriad of applications, while its sustainable attributes offer a path toward a greener industrial future. With an eye on environmental and economic challenges, the steel industry is pushing forward with advancements that promise enhanced quality, efficiency, and performance.

From the development of new steel alloys that offer superior properties to the implementation of cutting-edge technologies that increase production efficiency and reduce environmental impact, the steel industry is demonstrating resilience and a capacity for reinvention. The global trade of steel continues to be shaped by geopolitical, economic, and social factors, and industry players must remain agile to navigate this landscape successfully.

Looking ahead, the steel sector is poised to make significant contributions to some of the most pressing needs of our time, including infrastructure development, sustainable energy production, and the transition towards circular economic models. As the demands on steel products grow and shift, so too will the strategies and innovations of those who produce and trade in this essential material.

The future is bright for steel products, with unbounded potential for further growth and transformation, ensuring that steel will continue to play a fundamental role in building the world around us.

Understanding Steel: Key Insights & FAQs

What are the main benefits of using steel in construction?

Steel offers several advantages in construction, including a high strength-to-weight ratio, durability, versatility in application, and recyclability. Its ability to be prefabricated allows for faster construction times and minimal on-site labor.

Why is steel considered an eco-friendly material?

Steel is considered eco-friendly due to its high recyclability. It can be repeatedly recycled without degradation in quality, thus conserving natural resources, energy, and reducing waste in landfills.

How is steel produced?

Steel production involves several key processes: starting from the extraction of raw materials, followed by ironmaking in a blast furnace, steelmaking where impurities are removed, secondary steelmaking for further refinement, and finally casting, shaping, heat treatment, and finishing to produce various steel products.

What technological advancements are expected in the steel industry?

Advancements in material science are expected to produce new steel alloys with superior properties. Industry 4.0 technologies, including automation and AI, will likely improve efficiency and sustainability. The integration of renewable energy and electric arc furnace technology are also anticipated developments that will mitigate environmental impact.

How has steel recycling contributed to sustainability?

Steel recycling has contributed significantly to sustainability by saving energy, reducing greenhouse gas emissions, conserving natural resources, and reducing production costs. The use of scrap steel in electric arc furnaces is a prominent example of recycling in the industry, with many steel products containing high levels of recycled content.