Table of Contents:

Understanding Steel Production: A Brief Overview

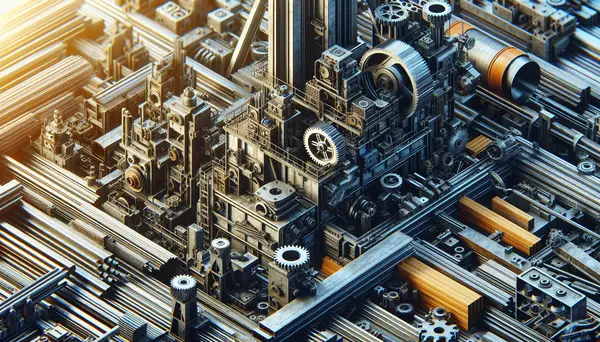

Steel, a ferrous alloy predominantly comprised of iron, is an essential material in our everyday life. It's in our cars, appliances, and even the buildings we work and live in. The production of steel is a complex process that involves several stages, from extracting raw materials from the earth to refining them into the durable and versatile metal we know. But what does this process entail? Let's delve a little deeper to understand the basics of steel production.

The initial step in steel production is the extraction of raw materials, primarily iron ore, coal, and limestone. The iron ore is transformed into iron in a process known as smelting. This involves heating the ore in a blast furnace alongside coke, a form of processed coal, and limestone. The resulting product, pig iron, is then further refined through a process known as steelmaking.

There are two primary methods of steelmaking: the Basic Oxygen Steelmaking (BOS) process and the Electric Arc Furnace (EAF) process. The BOS process involves blowing oxygen into molten pig iron to remove impurities and create steel. On the other hand, the EAF process uses electricity to melt scrap steel or direct reduced iron, creating new steel.

Once the steel is formed, it undergoes further refining to meet specific requirements—this phase is known as secondary steelmaking. The steel is then molded into various shapes and sizes to fit a multitude of applications. This is done through processes like casting, rolling, and forging. After shaping, the steel may go through additional processing, such as heat treatment—to alter its properties to make it even more durable and hardwearing.

In essence, steel production is a process that transforms raw materials into a material that is integral to modern living. However, it's worth noting that this overview only scratches the surface of what this process entails. There's a lot more happening behind the scenes that doesn't get as much attention.

The Common Misconceptions About Steel Production

When it comes to steel production, there are several misconceptions that often cloud the public's understanding of the process. One of the most common of these is the perception that all steel is created equal. In reality, there are countless variants of steel, each with its specific properties, compositions, and production methods. Whether it's carbon steel, alloy steel, or stainless steel, each kind demands a distinct manufacturing process to attain its unique characteristics.

Another common misconception involves the environmental impact of steel production. Many assume that steel production is solely damaging to the environment due to its high energy consumption and CO2 emissions. While it's true that steel production has its environmental implications, significant strides have been made towards sustainable steel production. Techniques such as recycling and reusing steel scrap, utilizing cleaner energy sources, and employing carbon capture technologies are just a few of the steps taken by the industry towards sustainability.

The idea that steel production is a fully automated process with no human involvement is also a prevalent myth. Yes, automation plays a crucial role in modern steel production—increasing efficiency, safety, and quality. However, human skills and expertise remain an indispensable component of the production process. Skilled workers are needed for important tasks such as quality control, maintenance, and even in operating and overseeing the highly advanced machines used in production.

Understanding these misconceptions isn't merely academic—demystifying these aspects of steel production can help us appreciate the complexity and importance of the industry. It can also inform our decisions as consumers, helping us make more sustainable choices.

Analysing Aspects Unaccounted in Steel Production

| Pros | Cons |

|---|---|

| Efficient manufacturing process | Does not consider environmental impact |

| Economically beneficial | Lack of sustainability practices |

| High production rate | No consideration of workers' conditions |

What Steel Production Does Not Include: Debunking Myths

The steel production process can often be misunderstood, leading to several misconceptions, some of which we've touched on. However, there are other aspects often falsely associated with steel production. By debunking these myths, we provide a clearer picture of what steel production does not include.

Contrary to popular belief, steel production does not solely rely on the extraction of fresh iron ore. The current steel production approach leans heavily on recycling; Scrap steel, or old steel products and materials, forms a significant part of new steel production. This recycling aspect not only makes steel production more sustainable but also reduces the need for iron ore extraction, a process with significant environmental impacts.

Furthermore, many assume that steel production ends when the steel is molded into various shapes for use, but this isn't the case. Steel manufacturing is not just about producing raw steel; it also includes 'downstream processes' - the creation of specific steel products such as rods, wires, plates, beams, etc. These downstream processes are an integral part of steel production and require distinct techniques and expertise.

Moreover, steel production is not a 'one-size-fits-all' process — it doesn't standardly produce a generic type of steel. There are thousands of steel grades, each with different compositional qualities catered for specific uses. The steel used to build your car, for example, could be quite different from the steel used in constructing bridges.

By dispelling these myths, we gain a more realistic picture of the steel production process. It's more than just simple metal fabrication - it's a complex system involving a myriad of processes, materials, and technologies.

Beyond the Surface: The Unseen Aspects of Steel Production

While we have debunked various myths and misconceptions about steel production, let's now delve into some aspects that often go unnoticed in the public eye. These are essential parts of the steel production process, providing us with an understanding that goes far beyond the surface.

One such factor is the role of research and development (R&D) in steel production. Today's steelmaking methods and technologies are the result of countless hours of research, experimentation, and innovation. The goal of R&D in this industry is not only continuous process improvement and cost reduction, but also to develop new types of steel with specific properties or to enhance environmental performance. These contributions often remain unseen, but they're crucial to the ever-evolving steel production landscape.

Another aspect is the emphasis on safety within the steel industry. As a sector involving handling heavy materials, working with high temperatures, and operating heavy machinery, safety is paramount in every step of steel production. From protective gear for workers to strict safety protocols, these safety measures are an important part of the production process often overlooked when discussing steel production.

The economic contribution of the steel industry is also significant but goes unnoticed amid discussions of production processes. The steel industry provides employment to millions of workers worldwide and contributes significantly to the global economy. Yet, this aspect is rarely at the forefront of our understanding of steel production.

By considering these unseen aspects of steel production, we can appreciate not only the steps taken to produce this widely used material, but also the numerous other factors that contribute to the industry as a whole.

The Impact of Steel Production on the Environment

Steel production is a resource-intensive process, and as such, its environmental impact is significant. This encompasses resource consumption, air and water pollution, waste generation, and substantial CO2 emissions. However, it's crucial to note that the steel industry has been implementing various strategies to reduce its environmental footprint. Let's explore this further to gain a balanced perspective.

The resource extraction phase of steel production, which includes mining for iron ore and limestone and harvesting of coal, comes with substantial environmental impacts. These range from land degradation and habitat loss to water pollution and emissions of hazardous pollutants. However, increased use of scrap steel in production can and is playing a massive role in easing these impacts.

The production process itself, particularly the smelting and refining stages, generates significant air pollutants, including sulphur, nitrogen oxides, and particulate matter. It also contributes to around 7-9% of global CO2 emissions. In response, many steel producers are investing in cleaner technologies and processes, including more efficient furnaces, carbon capture usage and storage (CCUS), and exploring hydrogen as a potential green energy source for steel production.

Recycling is an integral part of the steel industry's sustainability strategy. Steel is 100% recyclable and can be reused with no degradation in quality, making it a highly sustainable material.

The extent to which the steel industry can mitigate its environmental impact will significantly influence our transition towards a more sustainable world. As we continue to depend on steel for various aspects of our lives, responsible steel production is more critical than ever.

The Future of Steel Production: Innovations and Challenges

The future of steel production is inexorably tied to the challenges posed by the twin demands of increasing global steel demand and the urgent need for sustainable production methods. So, where is steel production headed, and what innovations are on the horizon to meet these challenges?

One exciting development is the use of hydrogen as a replacement for coal in the direct reduction of iron ore. "Green steel", as it's often referred to, produced via hydrogen-based reduction, can drastically decrease CO2 emissions, providing a pathway to more sustainable steelmaking. This process is still in its infancy, but trials are currently underway in several parts of the world.

Digitalization and the adoption of Industry 4.0 technologies are set to revolutionize steel production. Sports such as predictive maintenance, real-time monitoring and data analytics can increase efficiency, reduce waste and lower costs. At the same time, artificial intelligence and machine learning are increasingly being used to optimize steelmaking processes, improve product quality and enhance safety. These digital technologies could play a significant role in shaping the future of the steel industry.

Despite these promising developments, the industry faces significant challenges. Transitioning to low-carbon steelmaking, whether through the use of hydrogen or other methods, requires massive investments and supportive regulations. Furthermore, such innovations need to be scalable and commercially viable to meet the world's growing appetite for steel.

Overall, the future of steel production is poised to be a dynamic mix of challenges and opportunities. It will be a balancing act of meeting increasing global steel demand while transitioning towards more sustainable and resilient production processes. And in this quest, innovation will undoubtedly be key.

Conclusion: A Deeper Look into Steel Production

Steel production is much more than just the transformation of raw materials into a ubiquitous and versatile material—it's a reflection of human ingenuity and constant innovation. As we've seen, it involves several stages and systems, both seen and unseen, all working seamlessly together. It's an industry shaped by advances in technology and driven by a constant pursuit of efficiency and sustainability.

At the same time, it's an industry that, despite its essential role in modern life, is often misunderstood. It's these misunderstandings and oversights that we've sought to address here, providing a clearer picture of what steel production includes—and equally importantly, what it does not.

The challenges facing the steel industry are complex and multi-faceted, but these challenges also present opportunities for innovation. If history is any guide, steel production will continue to evolve, harnessing new technologies and processes to meet the world's growing demand for steel in a more sustainable, efficient, and responsible manner.

As we continue to rely on steel in our day-to-day life, understanding the intricacies of how it's produced allows us to better appreciate this remarkable material and the many ways it impacts our world—far beyond what meets the eye.

Uncovering the Hidden Aspects of Steel Production

What aspects of steel production are not commonly known?

There are several aspects to steel production such as the extensive use of recycled materials, energy efficiency practices, and numerous by-products including slag, gases, water and dust.

Are there environmental impacts of steel production?

Yes, steel production can have environmental impacts including air and water pollution. However, the steel industry has made significant improvements in reducing these impacts.

What happens to the by-products of steel production?

Many by-products of steel production can be reused. For example, slag can be used in road construction, and gases can be used for power generation.

How energy efficient is steel production?

With modern practices, steel production has become highly energy efficient and continues to improve with new technologies.

Why is recyclability important in steel production?

Steel is 100% recyclable, and the use of recycled materials in steel production reduces the need for mining raw materials, thus lessening environmental impact.