Posts on the Topic Electric-arc-furnace

Steel making machines have revolutionized the industry by increasing production speed, improving quality, and enabling precise designs through automation and advanced technology. Automation in steel production has evolved from manual processes to sophisticated machinery that enhances efficiency, safety, and sustainability...

Steelmaking universities offer a blend of theoretical and practical education in metallurgical engineering, focusing on the science behind metal properties and production processes. Students learn through courses ranging from thermodynamics to advanced materials engineering, with hands-on experience in modern labs...

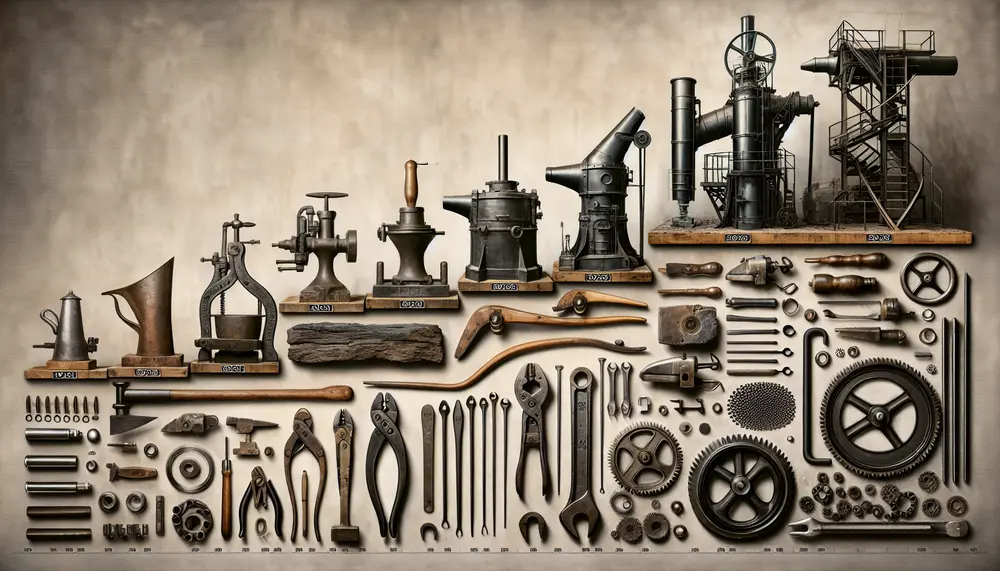

Steelmaking has evolved from early iron manipulation to advanced processes like the Bessemer method, which revolutionized mass steel production and infrastructure development. Technological advancements such as open hearth furnaces and electric arc furnaces further refined steel's properties, while British dominance...

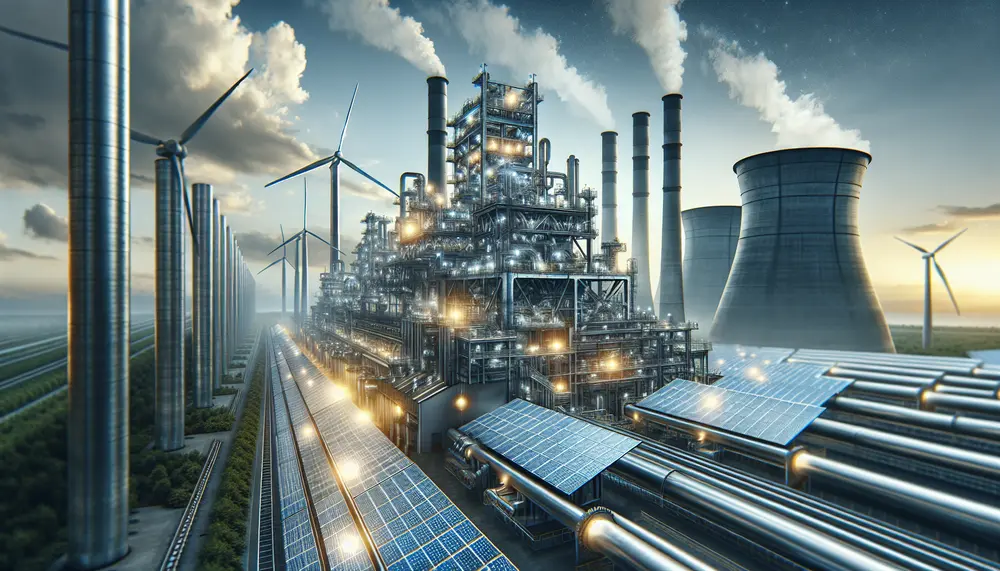

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...