Table of Contents:

Understanding the AM/NS Steel Making Process

The steel making process is a complex and nuanced operation, pivotal to the infrastructure of modern society. AM/NS, a joint venture between ArcelorMittal and Nippon Steel, stands at the forefront of innovation in this field. By breaking down the steel making process AM/NS employs, we gain insight into how steel is not only produced but also how these methods reflect the changing face of the industry.

At the heart of AM/NS's steel making process lies the integration of traditional methods with cutting-edge technology. The process begins with the collection and preparation of raw materials, primarily iron ore and coal. These materials are then subjected to high-temperature procedures to extract pure iron. Following this, the iron goes through a series of refining stages, which include melting, alloying, and shaping to achieve the desired steel properties. The entire operation is closely monitored to ensure optimal quality and efficiency.

AM/NS utilizes a combination of blast furnaces and electric arc furnaces (EAFs), showcasing flexible adaptation to both primary and secondary steel making strategies. The use of EAFs, in particular, signals a shift towards recyclability and sustainability, as this method allows the melting of scrap steel, reducing waste and the demand for raw materials.

Moreover, the steel production process at AM/NS showcases a significant commitment to environmental responsibility. Rigorous emission control measures are in place, ensuring the company's operations meet stringent environmental standards. This practice not only exemplifies efficient use of resources but also demonstrates AM/NS's role in leading the steel industry towards a more sustainable future.

The Evolution of Steel Production with AM/NS

The steel industry has undergone a profound transformation over the years, with AM/NS at the helm fueling progress and innovation. This evolutionary journey reflects a clear trajectory towards more sustainable and efficient production methods. AM/NS has consistently adapted its steel making process to align with global sustainability trends and technological advancements.

Technological Development is a driving force for AM/NS. The integration of digital technologies, such as artificial intelligence and the Internet of Things (IoT), has significantly elevated the efficiency and precision of the steel production operations. By implementing these technological solutions, AM/NS has reduced production times and increased product quality, setting new industry standards.

Central to AM/NS’s progression are strategic investments in research and development. Innovative solutions in the metallurgical processes have enabled the company to produce higher-grade steel that caters to the specific demands of diverse industries, ranging from automotive to construction. This specialized production capability has ensured that AM/NS remains a key player in a highly competitive global market.

Another notable change in the steel making landscape is the adoption of alternative energy sources. AM/NS has been investing in technologies that reduce carbon footprint and make use of cleaner energy in the production cycle. This not only enhances the energy efficiency of the plants but also contributes to a marked reduction in greenhouse gas emissions.

AM/NS's journey is a testament to its responsiveness to market demands, environmental responsibilities, and its unwavering pursuit of excellence. As a result, the brand has become synonymous with high-quality steel production that resonates with the future's ecological and technological expectations.

Comparative Analysis of AM/NS Steel Production Method

| Advantages | Disadvantages |

|---|---|

| Efficient production process | High initial investment costs |

| Reduced energy consumption | Potential for technical complexities |

| Lower greenhouse gas emissions | Requires skilled workforce for operation |

| Enhanced product quality and consistency | Limited flexibility in terms of production changes |

| Capability of recycling scrap metal | May not be suitable for all steel grades |

Key Innovations in the AM/NS Steel Production Method

Key innovations have been a cornerstone in the AM/NS approach to modernizing the steel making process. These advancements are critical to maintaining a competitive edge and to pushing the boundaries of what is possible in steel production.

One such innovation is the use of advanced analytics to enhance operational efficiency. By harnessing vast datasets across the manufacturing pipeline, AM/NS optimizes its processes in real-time, predicting maintenance needs, and minimizing downtime. This proactive approach not only saves time and resources but also maximizes output and longevity of the equipment.

In the realm of environmental stewardship, CO2 capture technology represents a monumental leap forward. AM/NS has implemented systems that capture and repurpose carbon emissions, turning what was once waste into a valuable resource. This initiative not only mitigates environmental impact but also aligns with global efforts to combat climate change.

To further enhance the recyclability of steel, AM/NS employs an innovative technique in their EAFs to increase the proportion of recycled materials used. This not only conserves primary resources but also addresses the growing need for sustainable manufacturing practices.

AM/NS's innovation extends into product development, where customizable steel grades are becoming increasingly available. By working closely with clients, AM/NS tailors the chemical composition and mechanical properties of steel products to meet specific requirements, opening up new applications and possibilities across various industries.

These key innovations emphasize AM/NS's commitment to pioneering a future in steel production that is efficient, sustainable, and highly adaptive to the needs of the global market.

Sustainability and Efficiency in AM/NS Steel Making

Sustainability and efficiency are embedded in the DNA of AM/NS's philosophy, with the organization undertaking robust measures to ensure that its steel making process is in harmony with the environment while optimizing performance.

An initiative that stands out is the XCarb™ program, designed to consolidate various sustainability efforts by AM/NS. This program includes green steel certificates, recycled and renewably produced products, and innovation fund investments aimed at achieving carbon-neutral steel by fostering advancements in green steelmaking technology.

Resource conservation is another strategic focus area for AM/NS. The company employs a water management system that significantly reduces water usage. By recycling and reusing water in its processes, AM/NS minimizes the overall consumption of this vital resource, reinforcing its commitment to eco-friendly production practices.

Furthermore, the energy management protocols in place at AM/NS ensure that energy consumption is optimized. The implementation of smart energy-saving solutions, along with a switch to renewable energy sources where possible, exemplifies the company’s strides towards energy efficiency.

By scrutinizing every step of the steel making process through an environmental lens, AM/NS is not only setting industry standards for sustainability and efficiency but is also demonstrating how responsible business practices can go hand in hand with commercial success.

The Role of Technology in AM/NS Steel Manufacturing

The role of technology in AM/NS steel manufacturing is transformative, driving forward an industry that blends centuries-old fundamentals with the digital age's innovations. AM/NS’s adoption of leading-edge technological tools is a game-changer in how steel is produced and delivered to the market.

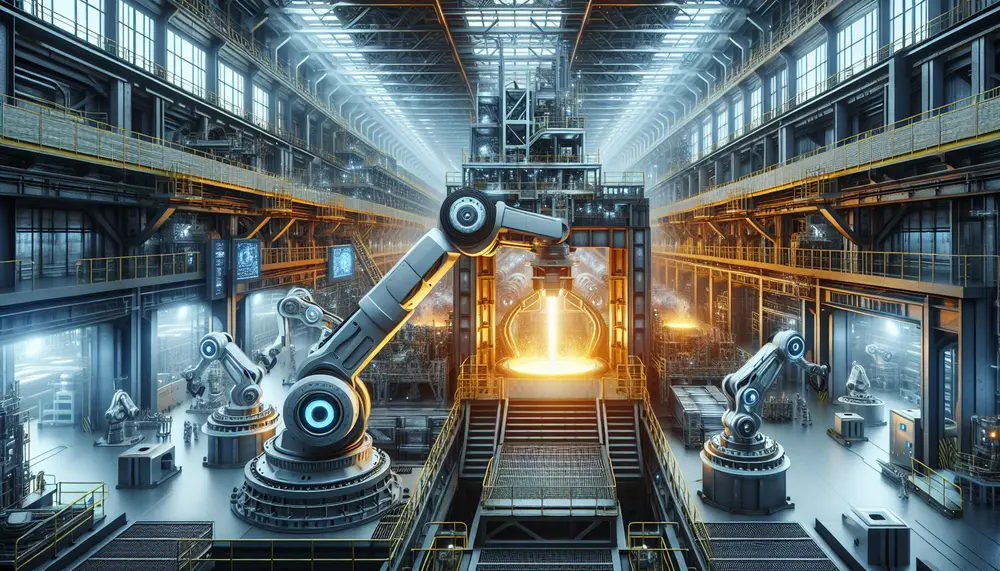

Foremost, automation and robotics have advanced the safety and precision in AM/NS factories. Automated processes ensure consistent product quality and reduce the exposure of workers to hazardous environments, echoing the #SafetyFirst ethos that AM/NS champions.

Data-driven decision-making further exemplifies AM/NS's technological integration. With comprehensive sensor networks and predictive analytics, the company can forecast equipment failures and process deviations, enabling preemptive action to be taken, thus ensuring continuous improvement in production efficiency.

At the core of AM/NS’s technology investments is the digital twin concept, which creates a virtual model of the steel plant that can be used for simulation and optimization. This not only enhances understanding and control over the steel making process but also paves the way for new levels of collaboration between different functional areas of the business.

Such technological leadership by AM/NS is not only cementing its status as a future-ready steel manufacturer but also redefining the potential of what technology can achieve within the industry.

Safety and Quality Control in the AM/NS Steel Making Process

Adherence to the highest standards of safety and quality control is paramount in the AM/NS steel making process, reflecting a corporate ethos that places the well-being of its workforce and the excellence of its products above all else.

Keeping in line with its #SafetyFirst priority, AM/NS has instituted rigorous health and safety protocols. Beyond the integration of automation which reduces the likelihood of accidents, on-site safety training programs are regularly conducted to ensure that all personnel are well-versed in best safety practices and emergency response procedures.

In terms of quality control, AM/NS employs a systematic approach throughout its production process. This begins with the meticulous selection of raw materials, followed by strict oversight at every stage of production to ensure that the final steel product meets the stringent quality standards that AM/NS and its customers expect.

The concept of continuous improvement is ingrained in the company's methodology, utilizing feedback loops and quality audits. These practices not only identify areas for improvement but also facilitate immediate corrective action, fostering an environment of perpetual advancement in quality control mechanisms.

The culmination of these concerted safety and quality control efforts ensures that AM/NS consistently delivers steel products of superior quality while protecting the most valuable asset - its workforce.

AM/NS and the Future of the Steel Industry

AM/NS is not just shaping the present landscape of the steel industry, but is also actively forging the path for its future. Through a potent combination of foresight and innovation, AM/NS is positioning itself as a vanguard of the next generation of steel production.

A commitment to ambitious goals like #Vision2030 demonstrates AM/NS's dedication to advancing the steel industry within a global context. This forward-looking framework is paving the way for new developments in industry practices, workforce empowerment, and cross-sectorial collaboration.

Community and educational programs, such as #BrighterFutures and partnerships in digital upskilling, exemplify the brand’s investment in society's future. By enhancing the skill set of the local workforce and broadening opportunities, AM/NS is strengthening the very foundation upon which the steel industry stands.

Through initiatives like the XCarb™ Innovations Fund, AM/NS is also betting on the entrepreneurial spirit to drive sustainability in the steel sector. Supporting climate-related startups places AM/NS at the heart of potential breakthroughs that can revolutionize how steel is produced and consumed.

With its finger on the pulse of the latest trends, challenges, and opportunities, AM/NS is not just participating in the steel industry's future; it is actively creating it.

Diversity and Inclusion in AM/NS Steel Production

Diversity and inclusion stand as core tenets in the corporate ethos of AM/NS, recognizing that a robust and diverse workforce is instrumental to driving innovation and reflecting the communities in which they operate.

AM/NS cultivates an inclusive work environment where varied perspectives are embraced and where individuals from all backgrounds are given the opportunity to thrive. Recruitment and retention strategies are crafted with the intention of building a team that mirrors the rich mosaic of the global community.

Furthermore, the company's inclusion programs ensure that all employees feel a sense of belonging. These programs are designed not only to support an equitable workplace but also to empower individuals to reach their greatest potential, contributing to the company's overall success.

AM/NS continues to break new ground by implementing innovative policies and programs that champion the importance of diversity. This commitment solidifies the organization's role as a leader in fostering an equitable and inclusive steel production industry.

AM/NS's Commitment to Education and Community Development

AM/NS's dedication to social responsibility extends far beyond its industrial operations, with a keen focus on nurturing the growth and development of the communities it serves.

Education is fundamental to this commitment, as demonstrated by their #BrighterFutures initiative. This long-term educational program seeks to uplift the potential of young people by enhancing access to quality schooling and learning resources. In collaboration with local stakeholders, AM/NS is helping to pave avenues for academic excellence.

The company’s efforts in community enrichment don't stop at education. A holistic approach has seen AM/NS engage in a range of programs aimed at bolstering healthcare, environmental conservation, and sports. These pillars form the bedrock of community empowerment, illustrating how AM/NS envisions the broader implications of its corporate influence.

Corporate philanthropy also manifests in its scholarship initiatives, like the partnership with Protean for the 'Beti Padhao' program. By awarding scholarships to deserving students, AM/NS invests in the intellectual capital that will drive future societal advancement.

The overarching goal of these community involvement strategies is clear: to facilitate sustainable development that benefits not just the steel industry but society at large. AM/NS is positioning itself not simply as an industrial giant, but as a catalyst for positive change in communities across the globe.

The Impact of AM/NS's Steel Making on the Environment

The environmental impact of steel production is a significant concern, with AM/NS conscientiously addressing this through innovative strategies and sustainable practices.

Acknowledging the carbon-intensive nature of traditional steel making, AM/NS has embarked on a pivotal journey to reduce its carbon footprint. Their proactive measures have included the upgrading of facilities and processes to decrease greenhouse gas emissions and increase energy efficiency.

A sterling example of this effort is AM/NS’s investment in renewable energy solutions. By diversifying their energy mix and incorporating more renewable sources, the company is reducing dependency on fossil fuels, a shift that significantly lessens environmental impact.

Waste management is another critical area where AM/NS excels, utilizing waste materials from the production process in other applications, thereby minimizing landfill use and promoting a circular economy—a model where nothing goes to waste and everything serves a purpose.

Through these concerted actions, AM/NS illustrates its unwavering resolve to not just comply with but to exceed environmental regulations, actively working to set a new benchmark for ecological responsibility in steel production.

Exploring the XCarb® Initiative by AM/NS

The XCarb® initiative represents AM/NS's visionary approach to decarbonizing the steel industry, and it stands as a hallmark of the company's environmental dedication.

This pioneering initiative is designed to consolidate a series of groundbreaking efforts, all of which are aimed at reducing carbon emissions associated with steel production. The XCarb® initiative encompasses several core components that together create a robust framework for achieving sustainable steel manufacturing.

One of the pillars of the XCarb® initiative is the Green Steel Certificates. These certificates provide a transparent mechanism for companies to invest in steel manufacturing that supports the production of steel with lower greenhouse gas emissions.

Another vital component of XCarb® is the innovation fund, which fuels the development of new technologies and processes that have the potential to revolutionize the steel making process in environmentally-sound ways. By nurturing such innovation, AM/NS is demonstrating its commitment to environmental stewardship.

The initiative also shines a spotlight on steel produced using recycled and renewable resources, promoting the use of greener materials and processes within the industry. This focus underscores a crucial shift towards more eco-conscious production methodologies.

Exploring the XCarb® initiative reveals AM/NS's comprehensive efforts to combat climate change and exemplifies how the company is leading the steel industry towards a greener, more sustainable future.

AM/NS's Vision 2030: Shaping the Future of Steel Making

AM/NS's Vision 2030 is a comprehensive roadmap aimed at transforming the landscape of steel making through sustainable practices and state-of-the-art innovation.

As a vital component of their long-term strategy, Vision 2030 represents a commitment to leadership in environmental conservation, technological advancement, and social responsibility. The goal is to not only advance in steel production but also to impact the industry positively and sustainably.

An integral focus of Vision 2030 is on empowering employees and fostering growth. Investing in people – through upskilling, fostering a diverse workforce, and ensuring a safe work environment – is a testament to the belief that a company's strength lies in its collective human capital.

Additionally, Vision 2030 encompasses the drive to expand globally, by leveraging partnerships and exploring new markets. This expansion is done with an acute awareness of the global sustainability goals and the pressing need to adapt business models to be both resilient and environmentally sound.

In implementing Vision 2030, AM/NS is not only strategizing for its own future success but is also actively sculpting the future of the steel industry, creating a blueprint for others to follow.

Partnerships and Collaborations: AM/NS's Strategy for Growth

AM/NS recognizes the immense value of partnerships and collaborations as pivotal elements of its strategic plan for growth and innovation within the steel industry.

The company's success can be partly attributed to its ability to forge strategic alliances across a broad spectrum of stakeholders — including governments, educational institutions, and technology firms. These collaborations are designed to symbiotically advance the capabilities and reach of all parties involved.

For example, AM/NS has partnered with entities like Festo India and the NSDC to enrich their workforce with advanced skills and training. These partnerships have not only enabled the development of a highly skilled team but also contributed to the upliftment of community standards of learning and employment.

Cooperative ventures, such as the aid provided to small and medium enterprises (SMEs) in association with the National Small Industries Corporation, reflect AM/NS's inclusionary growth ethos. Through such initiatives, AM/NS leverages its expertise to empower smaller businesses within the industry’s ecosystem.

This collaborative approach extends into research and development, particularly in the context of environmental sustainability where the XCarb® Innovations Fund encourages startups to innovate within the steel sector.

Each strategic partnership and collaboration nurtured by AM/NS is a step towards bolstering the steel industry, ensuring that growth is not only economically viable but also socially and environmentally responsible.

The Economic and Social Benefits of AM/NS Steel Production

The impact of AM/NS steel production extends well beyond the realm of industry, delivering profound economic and social benefits to the regions where it operates.

Financially, AM/NS acts as a powerhouse, stimulating the economy through job creation, infrastructure development, and the generation of substantial tax revenues. The presence of an AM/NS production facility can be a transformative event for a local economy, providing high-quality employment opportunities and fostering economic diversification.

Socially, AM/NS contributes to the fabric of communities through initiatives that promote education, health, and environmental stewardship. By building strong community relations, the company ensures that the benefits of steel production are inclusive and far-reaching.

Through vigorous investment in community programs, AM/NS aids in increasing the educational level and overall well-being of the societies it touches. Whether through scholarship programs, digital skills training, or health and sports initiatives, AM/NS is committed to making a lasting, positive mark on community life.

In sum, the economic and social advantages generated by AM/NS resonate throughout society, creating a legacy of prosperity, advancement, and communal harmony that mirrors the company's values of innovation and sustainable growth.

Conclusion: Why AM/NS Steel Making Process is Paving the Way Forward

In conclusion, the AM/NS steel making process is a beacon of progression in the industry, setting benchmarks for sustainability, technological innovation, and responsible production.

AM/NS's holistic approach to steel production combines environmental stewardship with economic vigor, resulting in a model that not only serves the needs of the present but also safeguards the interests of future generations. By relentlessly pushing the boundaries of technological advancement and maintaining a steadfast commitment to sustainable practices, AM/NS is indeed paving the way forward in the steel industry.

The company’s dedication to the wellbeing of its employees, investment in community development, and unwavering pursuit of excellence are what make AM/NS not just an industry leader, but a visionary in the truest sense. As we look towards a future that demands more eco-friendly and socially responsible practices, the AM/NS steel making process stands out as a prime example of what the future holds.

Ultimately, AM/NS embodies the paradigm shift that is essential for the steel industry's evolution, illustrating that through innovation, collaboration, and an ardent sense of purpose, the steel sector can continue to flourish in a rapidly changing world.

AM/NS India: Pioneering Sustainable Steel Production

What is the focus of AM/NS India's #Vision2030?

#Vision2030 is focused on enhancing the capabilities and growth of AM/NS India's employees, expanding its global footprint, and aligning operations with sustainability goals. It is a strategic framework aimed at transforming the steel industry through technological advancement and social responsibility.

How does AM/NS India prioritize sustainability in their production process?

AM/NS India emphasizes sustainability through initiatives like the XCarb® program and renewable energy investments. These efforts include reducing greenhouse gas emissions, conserving water, and implementing waste management practices to minimize environmental impact.

What technological innovations has AM/NS India introduced in steel production?

AM/NS India has implemented advanced analytics, CO2 capture technology, and the use of recycled materials in electric arc furnaces. Additionally, they focus on producing customizable steel grades to meet specific industry requirements. Their technology drive includes data-driven decision-making and automation to optimize the steel making process.

What are AM/NS India's initiatives in community and educational development?

AM/NS India's community and educational initiatives include the #BrighterFutures program, which enhances access to quality education. They also invest in healthcare, environmental conservation, and sports to enrich community life. Their partnership with Protean for 'Beti Padhao' scholarships supports further education for young people.

How does AM/NS India ensure safety and quality in their steel making process?

AM/NS India adheres to strict health and safety protocols, including automation to reduce accident risks and comprehensive safety training programs. Quality control is systematic, starting from the selection of raw materials to each production stage, to ensure all steel products meet high-quality standards.