Alloy steel

Alloy steel

Wenn wir von Alloy Steel sprechen, beziehen wir uns auf eine besondere Kategorie von Stahl, die durch das Mischen von Stahl mit einem oder mehreren weiteren Elementen erzeugt wird, um dessen Eigenschaften und Leistung zu verbessern.

Was ist Alloy Steel?

Alloy Steel ist eine Form des Stahls, die andere Elemente neben Eisen und Kohlenstoff enthält. Diese zugesetzten Elemente können Mangan, Nickel, Silizium, Titan, Kupfer, Chrom und Aluminium sein. Der Grund für diese Vermischung besteht darin, die mechanischen und physikalischen Eigenschaften von Stahl zu verbessern.

Eigenschaften von Alloy Steel

Die spezifischen Eigenschaften von Alloy Steel hängen weitgehend von den Elementen ab, die während des Herstellungsprozesses hinzugefügt werden. Im Allgemeinen kann er jedoch Eigenschaften wie hohe Zugfestigkeit, Haltbarkeit, Korrosionsbeständigkeit und gute Leitfähigkeit aufweisen.

Anwendung von Alloy Steel

Durch seine verbesserten Eigenschaften wird Alloy Steel in zahlreichen Industrien und Anwendungen eingesetzt. Dazu gehören die Automobilindustrie, die Luft- und Raumfahrt, die Energieerzeugung und -übertragung sowie die Bauindustrie.

Gewinnung und Handel von Alloy Steel

Die Herstellung von Alloy Steel beginnt mit der Gewinnung von Eisen und den zum Legieren verwendeten Elementen. Diese Materialien werden dann in Hochofen oder Elektroofen geschmolzen und zu der gewünschten Legierung vermischt. Hinsichtlich des Handels ist Alloy Steel aufgrund seiner vielfältigen Anwendungen ein bedeutender Akteur auf den globalen Stahlmärkten.

Fazit

Obwohl Alloy Steel komplexer in seiner Herstellung ist, bieten seine verbessernden Eigenschaften einen starken Mehrwert für viele Industriebranchen. Daher ist er ein wichtiger Faktor in der Stahlproduktion und im Stahlhandel weltweit.

Blog Posts with the term: Alloy steel

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

Steel's origins trace back to meteoric iron and evolved with human discovery of smelting around 2500 BCE, leading from the Bronze Age into the Iron Age. The Bessemer Process in the mid-19th century revolutionized steel production, enabling mass production and...

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...

HTS codes are essential for classifying steel products in international trade, determining tariffs and compliance with regulations. They require precise understanding due to their complexity and frequent updates influenced by global trade changes....

The article "Introduction to Ancient Steel Making" explores the historical context, key techniques, and materials used in ancient steel production across various civilizations. It highlights how early methods influenced modern steel making and underscores the ingenuity of our ancestors in...

Desulfurization in steelmaking is crucial for producing high-quality, durable steel by removing sulfur impurities that cause brittleness; advancements and techniques like desulfurizing agents, slag optimization, and vacuum treatment enhance this process while addressing challenges such as cost and environmental concerns....

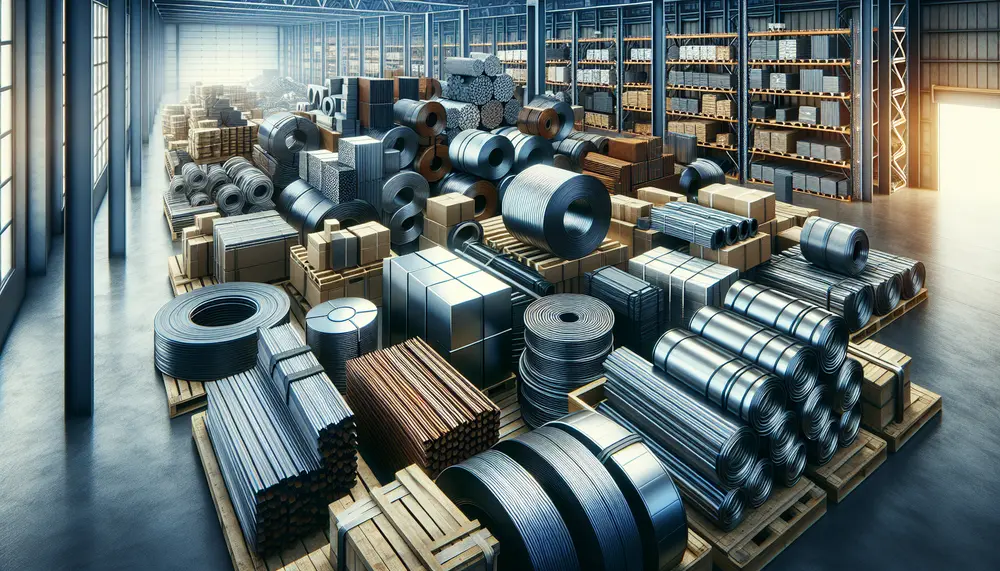

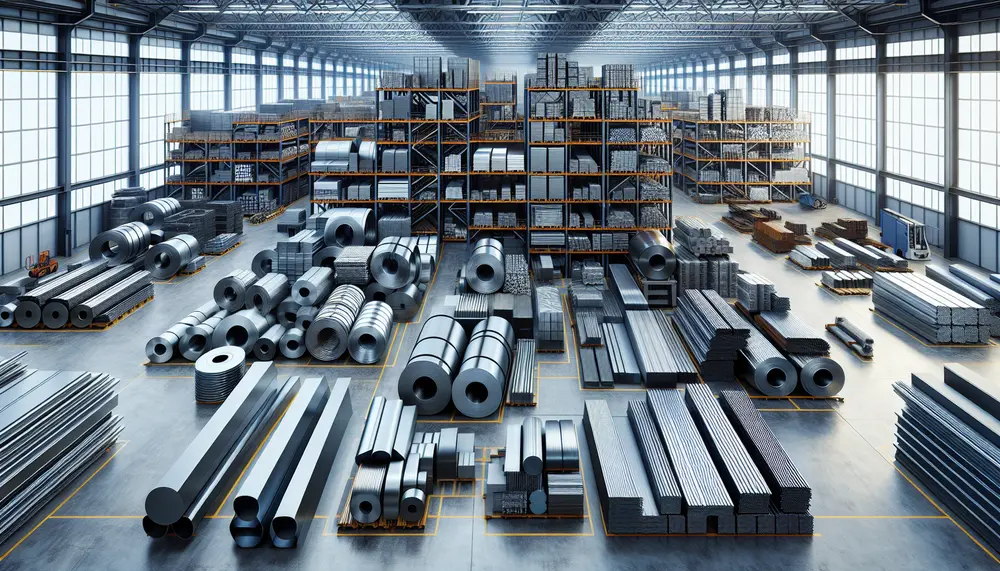

The steel products market is a vital, diverse industry integral to various sectors and driven by demand for durable materials. It's influenced by global economic trends, technological advancements, sustainability efforts, and competitive factors such as cost management and regulatory compliance....

Steel production, a significant indicator of a country's industrial prowess and economic health, is dominated by China which contributes nearly half of the global output. Other major players include India, Japan, Russia, South Korea, USA and Germany; each with unique...

Steel is an iron-carbon alloy with varying carbon content that determines its hardness, ductility, and tensile strength; other elements like chromium can be added to enhance specific properties such as corrosion resistance. Steel products are categorized into four main types:...

The steel industry in Thailand is a significant and growing sector, fueled by the country's economic growth, urbanization, and strategic location in Southeast Asia. Despite its robust domestic market and government support for industrial expansion, challenges such as high energy...

Steel making transforms iron ore into steel using blast furnaces or electric arc furnaces, involving processes like smelting and carbon adjustment to achieve desired properties. The production includes primary methods like Basic Oxygen Steelmaking and Electric Arc Furnace, followed by...

The article traces the evolution of steelmaking over nearly 4,000 years, highlighting key periods and innovations from ancient blacksmithing to modern techniques. It covers significant advancements such as Wootz steel in India, Chinese blast furnaces, medieval Damascus steel, and early...

The art of medieval steelmaking combined intuition, tradition, and a deep understanding of metallurgy to create strong yet flexible materials essential for tools, weapons, and status symbols. Despite limited scientific knowledge and resources, artisans mastered techniques like carbon infusion and...

Steel making is a complex process involving the production of steel from iron ore and scrap, where impurities are removed and alloying elements added to create different grades. The process includes two main steps: ironmaking (extracting iron from ore) and...

Steel production is a complex process combining traditional methods and modern technology to transform raw materials into versatile, durable products essential for industries like construction, automotive, energy, and consumer goods. Its adaptability ensures steel remains vital in innovation and sustainable...