Alloying element

Alloying element

Was ist ein Alloying Element?

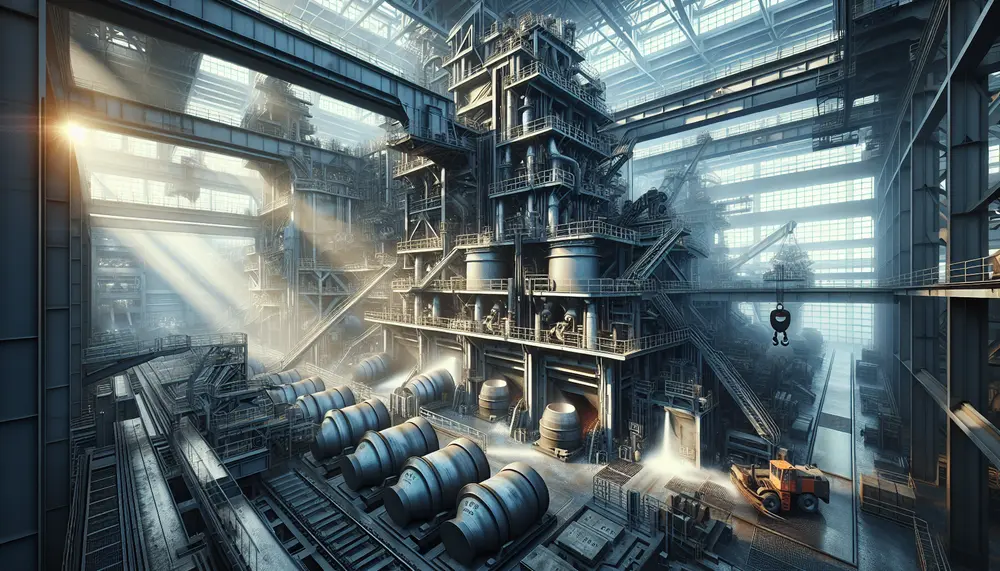

In der Welt der Stahlproduktion und des Stahlhandels ist der Begriff Alloying Element oder "Legierungselement" unvermeidbar. Ein Alloying Element ist ein Metall oder ein Nichtmetall, das dem Stahl während des Herstellungsprozesses zugesetzt wird, um seine Eigenschaften zu verändern und zu verbessern. Die Wahl des Legierungselements und dessen Menge hängen direkt von den gewünschten Endeigenschaften des Stahls ab.

Der Zweck von Alloying Elements

Mit dem Hinzufügen von Alloying Elements gewinnt der Stahl an Vielfalt und Flexibilität. Sie helfen, die Härte und Festigkeit, die Korrosionsbeständigkeit, die Zähigkeit, die Bearbeitbarkeit und sogar die Farbe des Stahls zu verbessern oder zu verändern. In anderen Worten, ohne Legierungselemente könnten wir nicht die breite Palette von Stahlsorten produzieren, die wir heute haben.

Häufig verwendete Alloying Elements

Es gibt viele verschiedene Alloying Elements, die in der Stahlproduktion eingesetzt werden. Einige der häufig verwendeten Legierungselemente sind Chrom, Nickel, Mangan, Molybdän und Vanadium. Jedes dieser Elemente hat einen einzigartigen Einfluss auf die Stahleigenschaften. Beispielsweise verbessert Chrom die Korrosionsbeständigkeit, während Nickel die Zähigkeit erhöht.

Schlussfolgerung

In der Welt des Stahlhandels helfen Alloying Elements, eine Vielzahl von Stahlsorten mit spezifischen Eigenschaften herzustellen. Daher haben Legierungselemente einen großen Einfluss auf die Qualität und Vielseitigkeit von Stahlprodukten. Letztlich erweisen sie sich als unverzichtbar in der modernen Stahlproduktion.

Blog Posts with the term: Alloying element

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

Mexico's steel industry has grown significantly due to rich resources, strategic location, skilled workforce, and modern technology. Challenges include high energy costs, competition from lower-cost countries, price fluctuations, and environmental concerns....

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

The article provides an overview of steel making, detailing its historical evolution and main processes such as ironmaking, primary and secondary steelmaking, casting, and forming; it highlights the importance of methods like the basic oxygen process and electric arc furnace...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

The VOD (Vacuum-Oxygen-Decarburization) steelmaking process is essential for producing high-quality stainless steel with very low carbon levels, crucial for applications like medical instruments and aerospace components. While it offers advantages such as enhanced decarburization and protection of alloying elements, its...

The steel making process, which starts with the extraction of iron ore and involves several steps to create different types of steel, is transitioning towards more sustainable methods like the Basic Oxygen Furnace (BOF) method. The BOF method turns raw...

The article "Introduction to Ancient Steel Making" explores the historical context, key techniques, and materials used in ancient steel production across various civilizations. It highlights how early methods influenced modern steel making and underscores the ingenuity of our ancestors in...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...

Steelmaking ladles are essential in the steel production process, designed to transport and refine molten metal while withstanding extreme temperatures and chemical corrosion. They come in various types tailored for specific functions such as transferring, treating, casting, and precise pouring...

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...

The Argon Oxygen Decarburization (AOD) process is essential in producing high-quality stainless steel by refining molten steel to reduce carbon content while preserving valuable alloying elements like chromium. This method, involving precise control of gas mixtures and temperatures during decarburization,...