Basic Oxygen Furnace

Basic Oxygen Furnace

Was ist ein Basic Oxygen Furnace?

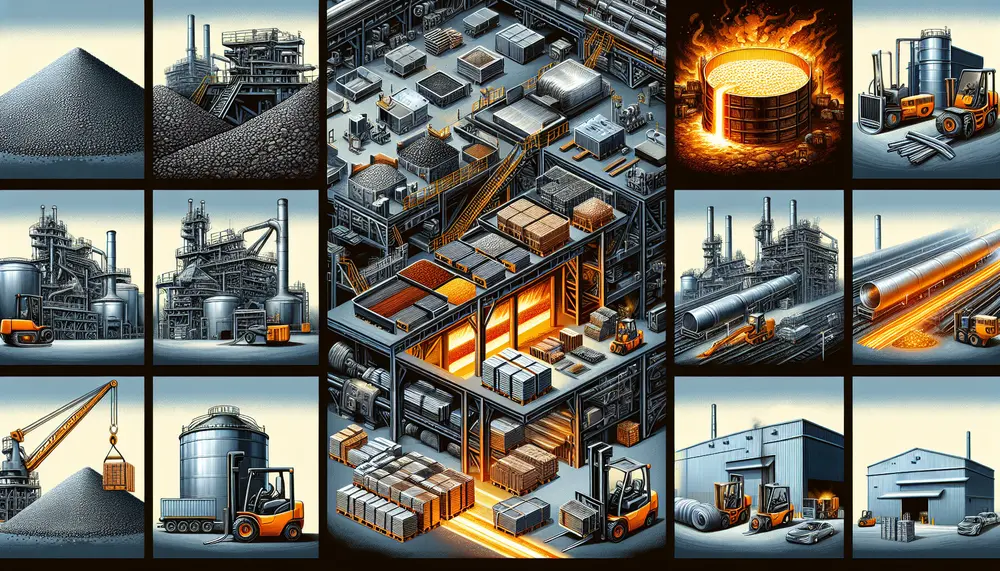

Ein Basic Oxygen Furnace (BOF) ist ein wichtiger Bestandteil der Stahlherstellung. Bei diesem Verfahren wird sauerstoffhaltiger Wind auf flüssigen Roheisen gestrahlt. Dieser Prozess führt zu einer intensiven Oxidation sowie Reduktion aller im Roheisen vorhandenen Elemente. Hierbei verbrennen Kohlenstoff und Silizium fast vollständig, während Phosphor und Mangan in das Schlackenbad aufsteigen.

Die Rolle des Basic Oxygen Furnace in der Stahlproduktion

Der Basic Oxygen Furnace hat eine entscheidende Rolle in der Stahlproduktion. Durch diese Methode können große Mengen an Stahl in einer relativ kurzen Zeit produziert werden, typischerweise in etwa 40 bis 50 Minuten. Dabei wird Molten Pig Iron (also noch nicht fertiggestellter Roheisen) gemeinsam mit Schrott in den Ofen gefüllt. Durch Zufuhr von Sauerstoff wird dann der eigentliche Prozess gestartet.

Der Vorgang in einem Basic Oxygen Furnace

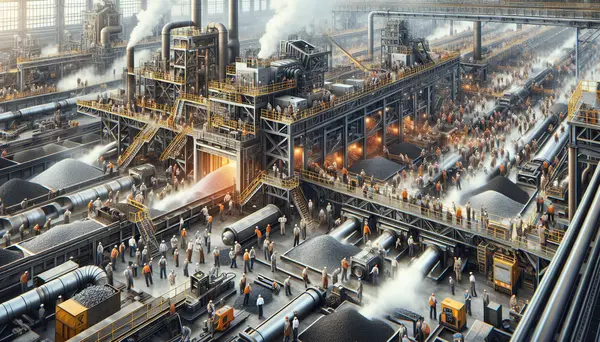

Innerhalb des Basic Oxygen Furnace wird der Ofen zunächst mit Molten Pig Iron und Schrott befüllt. Anschließend wird durch eine wasser-gekühlte Laterne, welche über dem Ofen thront, Sauerstoff zugeführt. Dieser Sauerstoff allerdings ist nicht Raumluft-Sauerstoff, sondern wird zuvor auf bis zu 1700 Grad Celsius erhitzt. Durch die starke Erhitzung findet ein chemischer Prozess statt, der die unerwünschten Elemente aus der Legierung holt, und damit das Material zu hochqualitativem Stahl umwandelt.

Die Vorteile des Basic Oxygen Furnace im Stahlhandel

Der Basic Oxygen Furnace ist ein wichtiger Faktor im Stahlhandel und treibt die Produktionskapazitäten auf ein hohes Niveau. Die Methode ist effizient und schnell, spart Energie und schafft ein hochqualitatives Endprodukt. Dadurch sind Stahlproduzenten in der Lage, den hohen Bedarf an Stahl in verschiedenen Industrien wie dem Bau, der Automobilindustrie oder dem Schiffsbau zu decken.

Zusammenfassung

Zusammengefasst bietet der Basic Oxygen Furnace eine wirkungsvolle und schnelle Methode zur Produktion von Stahl. Durch das Entfernen unerwünschter Elemente wird ein hochqualitatives Produkt hergestellt, welches zum globalen Handel beiträgt und für viele Industrien unentbehrlich ist.

Blog Posts with the term: Basic Oxygen Furnace

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

The African steel industry is growing and diverse, with varying levels of resource availability and technological sophistication across countries. It plays a crucial economic role by stimulating growth in other sectors, creating jobs, contributing to GDP, reducing import dependency, and...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...

Steel production is a highly energy-intensive process with significant environmental impacts, making the understanding and monitoring of energy consumption at each stage crucial for sustainability. Energy efficiency in steel manufacturing is essential for cost-effectiveness, competitiveness, and reducing carbon emissions, with...

Steel production, a complex process involving several stages from mining of raw materials to creation of the final product, significantly impacts the price and sustainability of steel. Understanding this value chain is crucial for decision-making in the industry as it...

The Open Hearth Process is a traditional steelmaking method that involves converting iron into steel using an open hearth furnace, which allows air to flow over the mixture and facilitates chemical reactions necessary for purification. This process utilizes regenerative heating...

Japan's steel industry rose from the post-WWII era to become a global leader through strategic investments in technology, quality control, and export-oriented policies. Key factors for this success include R&D commitment, high-quality standards, advantageous locations for trade routes, skilled workforce...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

The steel making process, which starts with the extraction of iron ore and involves several steps to create different types of steel, is transitioning towards more sustainable methods like the Basic Oxygen Furnace (BOF) method. The BOF method turns raw...

Lime is crucial in steelmaking, acting as a flux to remove impurities like phosphorus and sulfur, enhancing the quality of steel produced through processes such as EAF and BOF while also contributing to environmental sustainability by reducing emissions....

The article traces the history of steelmaking from early iron discoveries around 2,500 BCE to advanced techniques like Chinese cast iron production and Indian Wootz steel. It highlights key innovations such as smelting, forging by the Chalybes, and global influences...

The iron and steel industry is undergoing a new era of innovation, driven by advancements in automation, energy efficiency, and carbon reduction. Key trends include the use of AI and IoT for fully automated plants, advanced production technologies that require...