Converter

Converter

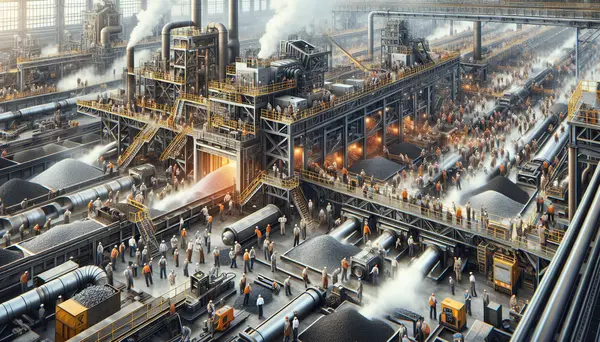

Wenn Sie die Welt der Stahlproduktion und des Stahlhandels erkunden, stoßen Sie auf einige spezielle Begriffe, die einzigartig für die Branche sind. Ein solcher Begriff ist Converter. Dieser hat eine wichtige Rolle in der Stahlherstellung und ist essenziell für das Verständnis des gesamten Prozesses.

Was ist ein Converter?

Ein Converter ist ein großer Behälter, der in der Stahlproduktion genutzt wird. Hier findet ein chemischer Prozess statt, der so genannte Konverterprozess. Dieses Verfahren ist ein zentraler Schritt in der Stahlherstellung.

Der Konverterprozess

Während des Konverterprozesses wird flüssiges Roheisen in Stahl umgewandelt. Zu Beginn des Ablaufs wird das flüssige Roheisen in den Konverter gefüllt. Sauerstoff wird hochgereinigt und mit hohem Druck in den Konverter geleitet. Dadurch verbrennen die verbliebenen Kohlenstoffreste. Es entsteht CO2, das wiederum aus dem Konverter entweicht. Übrig bleibt der flüssige Stahl.

Bedeutung des Converters im Stahlhandel

Aufgrund seiner essenziellen Rolle im Stahlproduktionsprozess hat der Converter auch eine hohe Bedeutung im Stahlhandel. Die Effizienz und Qualität der Converters beeinflussen direkt die Qualität und Wirtschaftlichkeit des produzierten Stahls. Investitionen in die Modernisierung und Verbesserung von Converters können direkt zur Steigerung des finanziellen Ertrags in der Stahlindustrie führen.

Es kann festgehalten werden, dass der Converter eine entscheidende Rolle in der Stahlproduktion und dem Stahlhandel spielt. Ohne ihn könnte der qualitativ hochwertige Stahl, den wir tagtäglich verwenden, nicht produziert werden. Unser Verständnis dieses Schlüsselwerkzeugs kann zu einer tieferen Wertschätzung für die komplexe Kunst und Wissenschaft der Stahlherstellung führen.

Blog Posts with the term: Converter

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

The article "Introduction to Steelmaking from Pig Iron" explores the historical and modern processes of transforming pig iron into steel, including methods like the Bessemer Process, Basic Oxygen Steelmaking (BOS), and Electric Arc Furnace (EAF). It highlights the importance of...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

South Korea is a key player in the global steel market, known for its production capacity, innovation, and high-quality specialty steels. The industry's economic impact on Korea includes job creation and skill development while driving foreign investment and technological advancement;...

The article provides an overview of steel making, detailing its historical evolution and main processes such as ironmaking, primary and secondary steelmaking, casting, and forming; it highlights the importance of methods like the basic oxygen process and electric arc furnace...

The article traces the history of steelmaking from early iron discoveries around 2,500 BCE to advanced techniques like Chinese cast iron production and Indian Wootz steel. It highlights key innovations such as smelting, forging by the Chalybes, and global influences...

The iron and steel industry is undergoing a new era of innovation, driven by advancements in automation, energy efficiency, and carbon reduction. Key trends include the use of AI and IoT for fully automated plants, advanced production technologies that require...

The article traces the evolution of steel making from its inception in the Iron Age to modern times. It highlights key milestones such as the Bronze Age's dawn of iron use, 17th century advancements in furnace technology and iron production,...

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...

The article explains the steel making process at SAIL Bokaro, highlighting its precision and adherence to quality and environmental standards. It details the journey from raw materials like iron ore, coal, and limestone through various stages including blast furnaces and...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

The POSCO steel making process is a sophisticated combination of technology and environmental care, producing high-quality steel through efficient, innovative methods like the FINEX technology. This multi-stage production includes ironmaking, refining in a basic oxygen furnace during the converter phase,...