Durability

Durability

Was ist Durability?

Der Begriff Durability bezieht sich auf die Fähigkeit eines Materials, über die Zeit unter verschiedenen Bedingungen zu bestehen, ohne seine grundlegenden Eigenschaften zu verlieren. In der Stahlproduktion und im Stahlhandel spielt die Durability eine besonders wichtige Rolle. Das liegt daran, dass Stahl häufig in Umgebungen eingesetzt wird, die hohen physikalischen oder chemischen Beanspruchungen unterliegen.

Warum ist Durability bedeutend im Stahlhandel?

Stahl ist ein Material, auf das sich viele Branchen verlassen. Vom Bauwesen über die Autoindustrie bis hin zur Produktion von Haushaltsgeräten. Sie alle brauchen Stahl, der dauerhaft hält, was er verspricht. Daher ist die Durability des Stahls eine wesentliche Eigenschaft. Sie ist entscheidend dafür, wie lange ein Produkt oder eine Konstruktion hält und wie hoch die Wartungskosten sind. Die Langlebigkeit des Stahls hat auch starke Auswirkungen auf die Umwelt, da sie bestimmt, wie oft ein Produkt ersetzt werden muss und wie viel Abfall dabei entsteht.

Welche Faktoren bestimmen die Durability von Stahl?

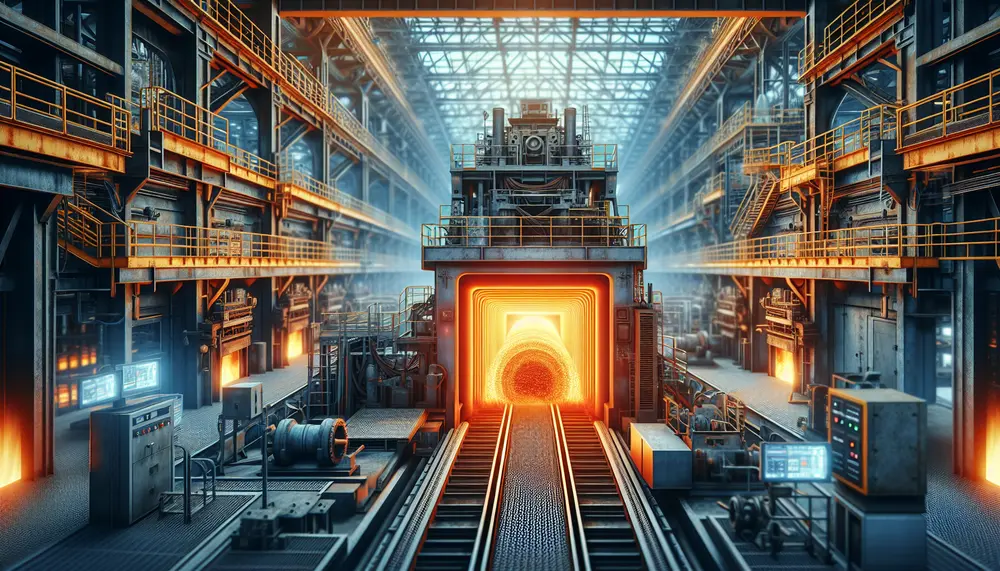

Die Durability vom Stahl hängt von einer Reihe von Faktoren ab. Dazu gehören die Qualität des Rohmaterials, die Art der Verarbeitung, die Wärmebehandlung und die Endoberflächenbehandlung. Auch die spezifische Zusammensetzung des Stahls spielt eine Rolle. Bestimmte Legierungselemente können die Durability erhöhen, indem sie die Korrosionsbeständigkeit verbessern oder die Härte des Materials erhöhen.

Wie wird die Durability von Stahl gemessen?

Es gibt verschiedene Methoden, um die Durability von Stahl zu messen. Eine gängige Methode ist der Korrosionstest. Dabei wird der Stahl verschiedenen schädlichen Umgebungen ausgesetzt, um zu sehen, wie er sich mit der Zeit verhält. Es gibt auch mechanische Tests, die dazu dienen, die Belastbarkeit und Haltbarkeit des Stahls unter unterschiedlichen Bedingungen zu messen.

Blog Posts with the term: Durability

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...

Steel's origins trace back to meteoric iron and evolved with human discovery of smelting around 2500 BCE, leading from the Bronze Age into the Iron Age. The Bessemer Process in the mid-19th century revolutionized steel production, enabling mass production and...

Steel was crucial in World War II, serving as the backbone for military equipment and influencing nations' industrial might. The escalation of steel production played a pivotal role in the Allied victory, with advancements in technology and massive job creation. Steel's...

The manufacturing of steel balls is a complex process involving precise steps to produce high-quality products for various applications. It starts with selecting the right raw materials and includes forging, flashing, heat treating, grinding, lapping, and rigorous inspections to ensure...

South Korea's steel industry has evolved into a global leader through strategic government investments, innovation in eco-friendly technologies, and significant contributions to the economy....

South Korea is a key player in the global steel market, known for its production capacity, innovation, and high-quality specialty steels. The industry's economic impact on Korea includes job creation and skill development while driving foreign investment and technological advancement;...

Japan's steel industry rose from the post-WWII era to become a global leader through strategic investments in technology, quality control, and export-oriented policies. Key factors for this success include R&D commitment, high-quality standards, advantageous locations for trade routes, skilled workforce...

The article provides an overview of steel making, detailing its historical evolution and main processes such as ironmaking, primary and secondary steelmaking, casting, and forming; it highlights the importance of methods like the basic oxygen process and electric arc furnace...

The VOD (Vacuum-Oxygen-Decarburization) steelmaking process is essential for producing high-quality stainless steel with very low carbon levels, crucial for applications like medical instruments and aerospace components. While it offers advantages such as enhanced decarburization and protection of alloying elements, its...

Induction furnaces have transformed steel making with their efficiency, versatility, and reduced environmental impact compared to traditional fossil fuel-based furnaces. They use electromagnetic induction for heating metals precisely and quickly, offering benefits like energy savings, improved productivity, metallurgical control, scalability,...