Flat products

Flat products

Was sind Flat Products?

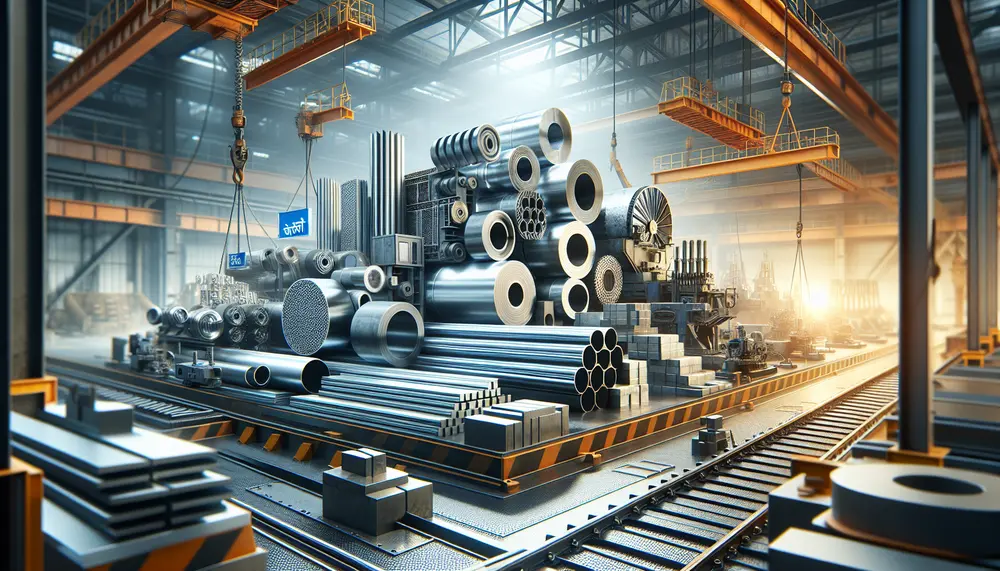

Bei Flat Products handelt es sich um eine wichtige Kategorie im Bereich der Stahlproduktion und des Stahlhandels. Im Allgemeinen bezeichnet der Begriff eine Auswahl von Stahlprodukten, die aufgrund ihres Herstellungsprozesses flache, rechteckige Formen aufweisen.

Arten von Flat Products

Flat Products enthält eine Reihe verschiedener Erzeugnisse. Dazu gehören unter anderem warm- und kaltgewalzte Bleche, beschichtete Bleche und Platten. All diese Stahlprodukte zeichnen sich durch ihre flache Morphologie aus und haben diverse Verwendungen in einer Vielzahl von Industrien.

Herstellung von Flat Products

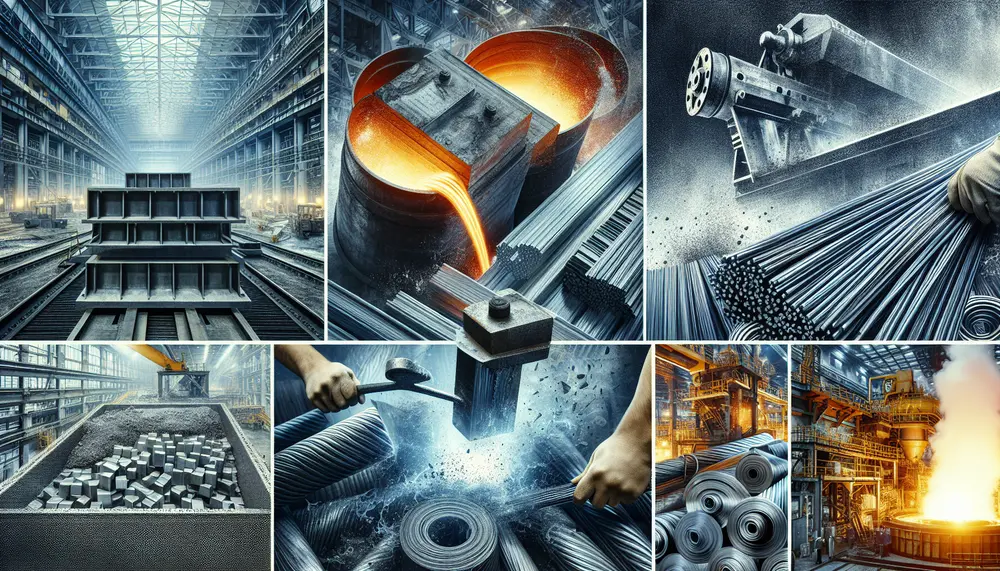

Die Herstellung von Flat Products erfolgt durch Walzprozesse. Stahl wird auf hohe Temperaturen erhitzt und dann durch Walzwerke geführt. Die Walzen pressen den Stahl in flache, dünne Platten. Bei warmgewalzten Blechen erfolgt dies bei einer Temperatur, die über der Wiedererwärmungstemperatur des Stahls liegt. Kaltgewalzte Bleche hingegen werden bei Zimmertemperatur bearbeitet, was zu einer feineren Oberfläche und höherer Maßgenauigkeit führt.

Anwendungsbereiche von Flat Products

Die Verwendung von Flat Products ist äußerst vielseitig. Diese Stahlprodukte spielen eine entscheidende Rolle in der Bauindustrie, der Automobilindustrie und der Schiffbauindustrie. Ebenso sind sie essenziell im Bereich des Maschinenbaus und der Herstellung von Haushaltsgeräten. Ihre flache Form erleichtert das Schneiden, Formen und Schweißen, was sie ideal für diese industriellen Anwendungsbereiche macht.

Fazit

Flat Products bilden eine unverzichtbare Kategorie von Stahlprodukten mit breiten Anwendungsmöglichkeiten in verschiedenen Industrien. Ihr flaches Format resultiert aus speziellen Walzprozessen und ermöglicht eine einfache Weiterverarbeitung.

Blog Posts with the term: Flat products

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The global steel industry is a critical component of modern infrastructure and economic growth, with production levels indicative of a country's development stage. China dominates the market as the largest producer, while other key nations like Japan, Germany, and India...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

Turkey's steel industry is a key economic pillar, known for its high-quality production and strategic location that bridges Europe and Asia. Despite challenges like raw material dependency and global price fluctuations, the sector has shown resilience through innovation and contributes...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

Steel manufacturing from scrap is a sustainable process that reduces environmental impact and conserves resources. It involves collection, separation, melting in an electric arc furnace, refining to remove impurities, adding alloy elements, and casting into new products; recycling steel offers...

The steel industry in Thailand is a significant and growing sector, fueled by the country's economic growth, urbanization, and strategic location in Southeast Asia. Despite its robust domestic market and government support for industrial expansion, challenges such as high energy...

A steel product is an item predominantly made of steel, known for its durability and versatility across industries, with a wide range of forms and applications. Understanding these products involves knowledge of the production process from raw materials to finished...

The article provides a comprehensive guide to steel production, simplifying core concepts for beginners and detailing key processes such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) methods. It covers essential steps from ironmaking to finishing, offering...

Steel production in Malaysia, utilizing the Electric Arc Furnace method and benefiting from its ASEAN location, has grown significantly due to domestic demand and government initiatives like NIMP 2030. The industry faces challenges such as environmental impact but remains a...

India has risen as a global leader in steel production, recognized for its quality and innovation due to historical expertise, modern advancements, and strong policy support. The industry's growth is driven by key players like JSW Steel and Tata Steel...

This beginner's guide to steelmaking explains the basic processes and terminology involved in transforming iron ore into versatile steel, highlighting key terms like blast furnace, continuous casting, and electric arc furnace. It details the journey from raw material to finished...

Steel manufacturing is vital for modern industry, with blast furnaces and electric arc furnaces as core methods; innovation drives efficiency, sustainability, and tailored properties....