Formability

Formability

Formbarkeit - eine Schlüsselrolle in der Stahlproduktion und im Stahlhandel

Beim Durchblättern des Themengebiets Stahlproduktion und Stahlhandel treffen Sie häufig auf den Begriff Formbarkeit. Aber was bedeutet er genau? Die Formbarkeit ist ein wichtiger Begriff, der die Fähigkeit eines Materials - in diesem Fall Stahl - beschreibt, sich ohne Bruch oder Rissbildung formen zu lassen.

Anwendung der Formbarkeit in der Stahlproduktion

Im Prozess der Stahlherstellung spielt die Formbarkeit eine entscheidende Rolle. Sie bestimmt, wie einfach oder schwierig es ist, den Stahl in die gewünschte Form zu bringen. Einfacher ausgedrückt, je höher die Formbarkeit eines Stahls ist, desto leichter lässt er sich formen. Dies beeinflusst sowohl die Kosten als auch die Qualität des Endprodukts.

Formbarkeit und Stahlqualität

Eine gute Formbarkeit ist oft Synonym für hochwertigen Stahl. Ein Stahl mit hoher Formbarkeit kann komplexere Formen annehmen, ohne zu reißen. Dies macht ihn ideal für anspruchsvolle Anwendungen wie Automobilkarosserien oder Präzisionswerkzeuge.

Messung der Formbarkeit

Die Formbarkeit eines Stahls kann durch verschiedene technische Tests bestimmt werden. Einige dieser Tests umfassen das Zug-, Druck- und Biegeverhalten des Stahls. Dabei ermöglicht eine hohe Formbarkeit eine größere Formänderung ohne Bruch oder Beschädigung.

Zusammengefasst ist die Formbarkeit eine wichtige Eigenschaft von Stahl. Sie beeinflusst die Produktion, Qualität und Anwendung des Stahls erheblich. So spielt die Formbarkeit eine Schlüsselrolle in der Stahlbranche und wird bei der Auswahl des richtigen Stahls für ein bestimmtes Projekt sorgfältig berücksichtigt.Blog Posts with the term: Formability

The Argon Oxygen Decarburization (AOD) process is a secondary steel making method that refines the composition of steel by reducing carbon content, using oxygen and inert gases like argon for controlled reactions. This technology allows for high-quality alloy production with...

South Korea is a key player in the global steel market, known for its production capacity, innovation, and high-quality specialty steels. The industry's economic impact on Korea includes job creation and skill development while driving foreign investment and technological advancement;...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...

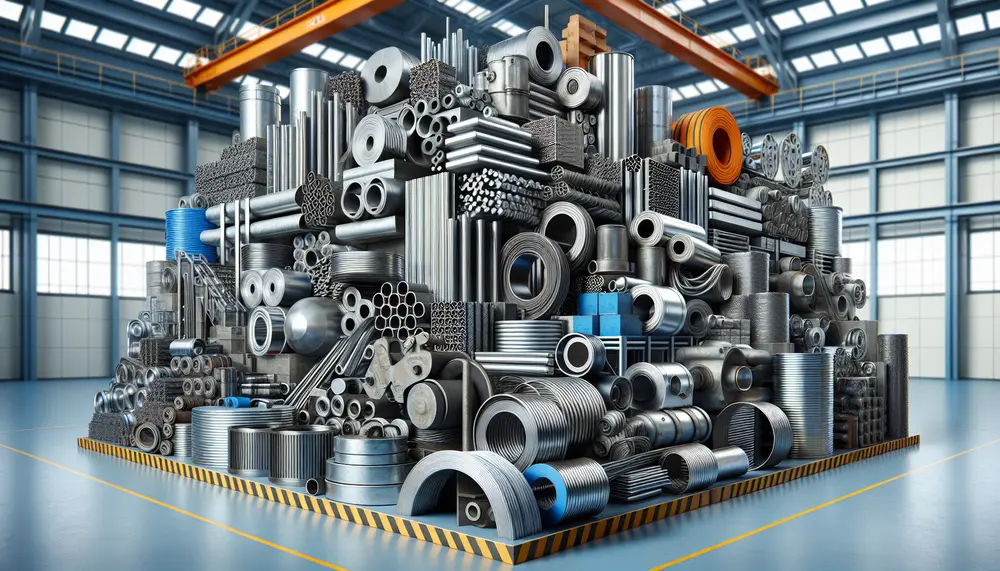

The article provides an in-depth look at the role of steel products across various industries, highlighting their diverse applications and importance. It covers the basics of steel production, compares uses in different sectors, explains differences between hot-rolled and cold-rolled steel,...

The article explains the steel production process using a detailed steelmaking diagram, which visually breaks down each step from raw material preparation to finishing processes. It covers two main methods of steelmaking—Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF)—and...

Steel is an iron-carbon alloy with varying carbon content that determines its hardness, ductility, and tensile strength; other elements like chromium can be added to enhance specific properties such as corrosion resistance. Steel products are categorized into four main types:...

RH technology, initially developed for hydrogen removal in steel making, now plays a crucial role in secondary refining and purification to ensure high-quality steel production. Key advancements like oxygen lances, powder injection systems, the RH-TOP system, and modern vacuum pumps...

The article provides a comprehensive guide to steel production, simplifying core concepts for beginners and detailing key processes such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) methods. It covers essential steps from ironmaking to finishing, offering...

Secondary steelmaking refines and adjusts the composition of steel to meet specific standards, involving processes like deoxidation, desulfurization, decarburization, alloying, and degassing. It is crucial for producing high-quality steel with desired properties such as strength and corrosion resistance. The role of...

Stainless steel making is a complex process that begins with melting iron ore and other elements like chromium and nickel to create a durable, corrosion-resistant material. This involves several stages including refining, casting, and rolling, controlled by precise temperature and...

Vacuum degassing is a critical process in steel production that enhances the quality of steel by removing dissolved gases like hydrogen, oxygen, and nitrogen under vacuum conditions to prevent issues such as porosity and embrittlement. This method not only improves...

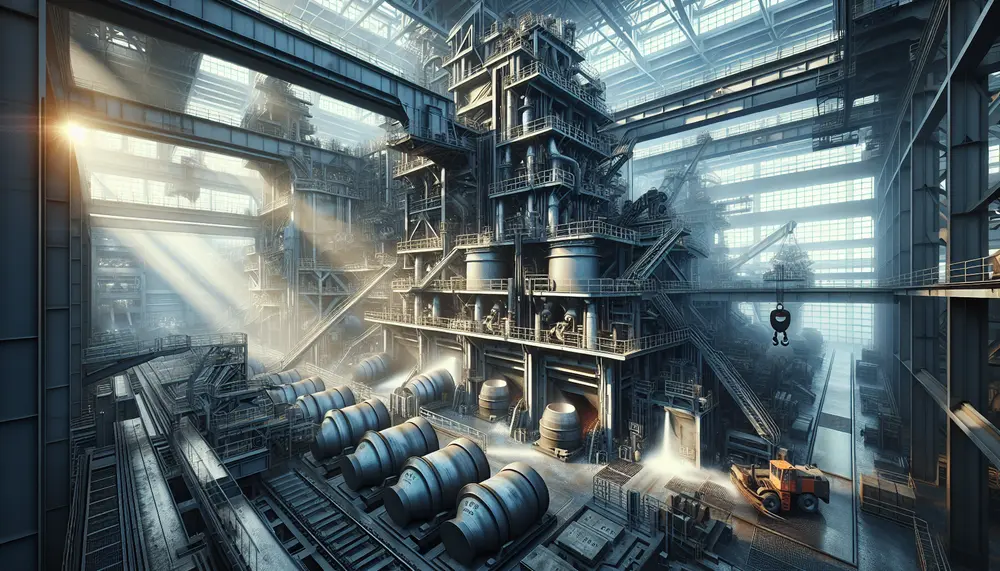

Modern steel factories combine advanced technology, automation, and strict quality control to transform raw materials into high-quality steel with precision and efficiency....

Steel refining transforms raw materials into high-quality steel by removing impurities and enhancing properties through advanced techniques like BOF, EAF, and DRI. Modern innovations ensure precision, efficiency, sustainability, and tailored applications across industries while addressing environmental challenges....