Gauge

Gauge

Was ist ein Gauge?

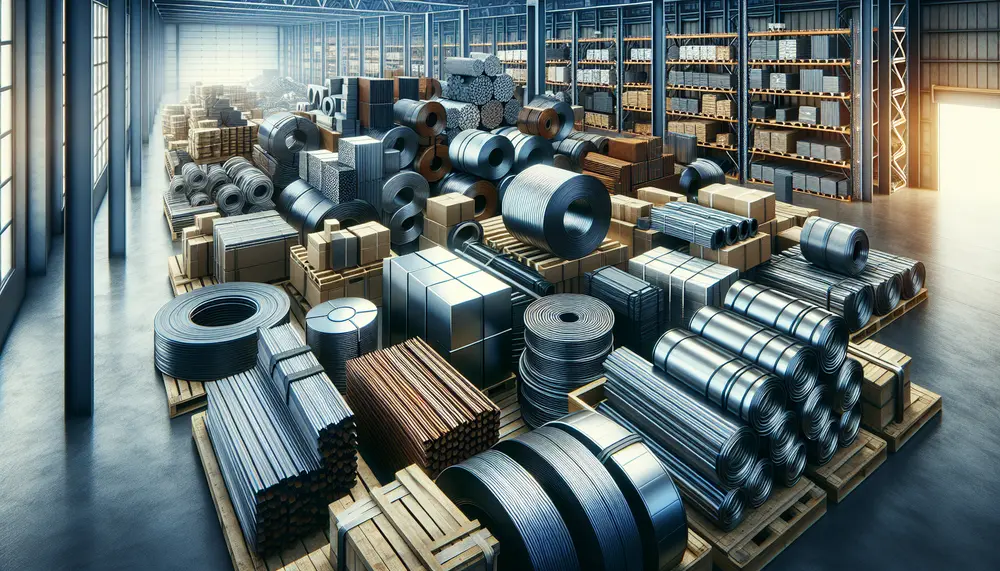

Ein Gauge ist ein Begriff, den wir im Bereich von Metallprodukten und insbesondere in der Steel production and steel trade verwenden. Es bezieht sich auf die Dicke, den Durchmesser oder die Größe eines Metallteils, normalerweise dargestellt durch eine Zahl. Im Kontext der Stahlproduktion kann der Begriff Gauge auf die Dicke eines Stahlblechs oder den Durchmesser eines Drahtes, einer Stange oder eines Rohres anwenden.

Die Bedeutung von Gauge in der Stahlproduktion und im Stahlhandel

Die Kenntnis der Gauge ist für Stahlproduzenten, Händler und Nutzer sehr wichtig. Sie bestimmt die Qualität und Nutzung eines Stahlprodukts. Zum Beispiel kann ein Stahlblech mit niedriger Gauge dicker und stärker sein, weshalb es besser für strapazierfähige Anwendungen geeignet ist. Eine hohe Gauge hingegen bedeutet ein dünnes und leichtes Material, das für feinere Arbeiten verwendet wird. Die Gauge ist daher ein entscheidender Faktor, der die Verwendung und den Preis eines Stahlprodukts bestimmt.

Gauge-Messungen verstehen

In der Stahlbranche sind Gauge-Messungen nicht universell. Der Gauge-Wert kann basierend auf der Art des Metalls und dem Land, in dem es hergestellt wird, variieren. In den USA beispielsweise unterscheidet sich die Gauge-Messung für Eisen und Stahl von der für Aluminium und Kupfer. Es ist wichtig, den Unterschied zu kennen und sicherzustellen, dass Sie die korrekte Gauge für Ihre speziellen Bedürfnisse auswählen. Viele Unternehmen stellen Gauge-Konvertierungstabellen zur Verfügung, um Verwirrung zu vermeiden und den Handel zu erleichtern.

Blog Posts with the term: Gauge

HTS codes are essential for classifying steel products in international trade, determining tariffs and compliance with regulations. They require precise understanding due to their complexity and frequent updates influenced by global trade changes....

Steel manufacturing from scrap is a sustainable process that reduces environmental impact and conserves resources. It involves collection, separation, melting in an electric arc furnace, refining to remove impurities, adding alloy elements, and casting into new products; recycling steel offers...

The art of medieval steelmaking combined intuition, tradition, and a deep understanding of metallurgy to create strong yet flexible materials essential for tools, weapons, and status symbols. Despite limited scientific knowledge and resources, artisans mastered techniques like carbon infusion and...

Steelmaking without coal, utilizing electricity and hydrogen from renewable sources, offers a sustainable alternative to traditional methods by reducing carbon emissions. The shift towards green steel production is driven by innovations like electric arc furnaces and low-carbon materials, with industry...

Steelmaking capacity is crucial for understanding the steel industry's dynamics, with factors like plant size and technology influencing production levels; the OECD plays a key role in monitoring global capacity, promoting sustainable practices, and addressing challenges such as overcapacity through...

A well-structured PowerPoint on stainless steel manufacturing uses clear visuals and icons to simplify complex processes, enhance understanding, and support actionable insights....

Steel wire products are known for their strength, durability, and flexibility, making them essential in various industries. They can be customized into different shapes and sizes using modern technology and made from various steel grades to meet specific needs across...

Steel production statistics are essential for assessing the global economy and steel industry health, reflecting industrial activity and economic trends through raw output and capacity utilization rates. These figures are influenced by technological advancements, market demands, trade policies, environmental considerations,...

The article discusses the importance of visual imagery in understanding and appreciating the steel making process, highlighting how photography can capture each stage—from raw material handling to finishing—and transform industrial scenes into compelling art. It emphasizes that high-quality images not...

Steel roofing products are highly durable, offering long-term strength and resistance to weather, pests, and fire with minimal maintenance required. They also provide cost-effectiveness over time due to low lifecycle costs, energy savings from thermal reflection, potential insurance discounts, and...

The steel production outlook for 2023 and beyond is influenced by economic, technological, environmental factors, and demand from construction and automotive sectors. Innovation in sustainable practices and technology are key to the industry's future competitiveness and alignment with global sustainability...

Steel production is a critical process that creates an alloy of iron and carbon, essential for various industries. It involves extracting iron ore, refining it into steel with specific carbon content through methods like basic oxygen steelmaking or electric arc...

Steel, an alloy of iron and carbon, has been instrumental in shaping modern architecture due to its strength, durability and malleability. Its use dates back to the 1800s but it revolutionized architecture in the 20th century with large-span structures and...

Forecasting steel production is crucial for planning in industries and governments, involving analysis of economic indicators, market trends, and geopolitical factors to predict future output. Accurate forecasts are vital as they inform decision-making processes across various sectors by anticipating supply-demand...

Steel production volume trends are crucial for understanding the global economy, influenced by supply and demand dynamics, macroeconomic factors, technological advancements, and environmental regulations. The global steel industry is diverse with China as a leading producer; regional variations in production...