Ingot

Ingot

Was ist ein Ingot?

Ein Ingot ist ein wesentlicher Begriff im Bereich der Stahlproduktion und des Stahlhandels. Es handelt sich dabei um einen Massenblock aus Metall, der in einer speziellen Form gegossen wird. In der Regel sind Ingots das Ergebnis des ersten Schmelzprozesses und dienen als Ausgangsmaterial für weiteres Formen und Bearbeiten.

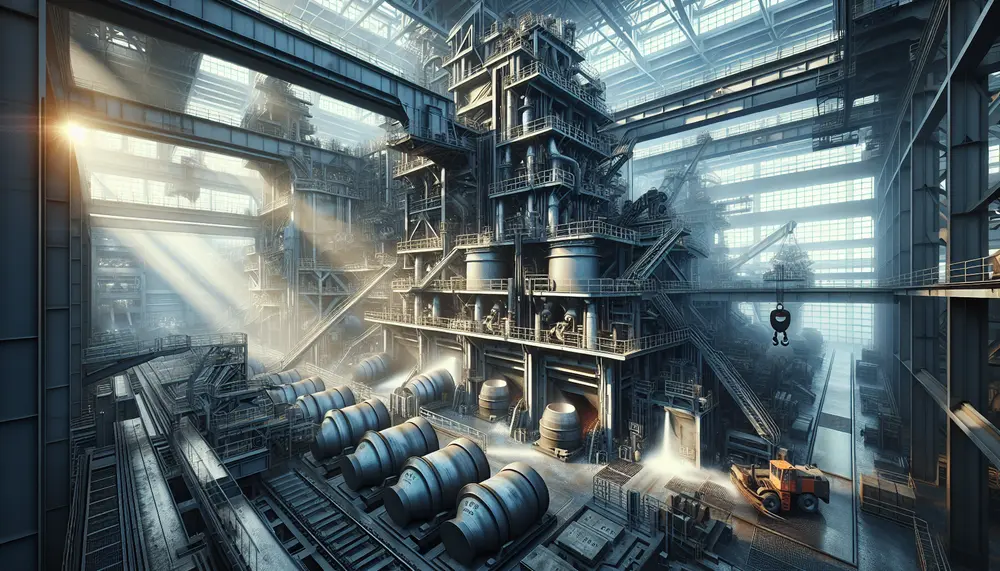

Der Ingot in der Stahlproduktion

In der Stahlproduktion ist der Ingot der erste physische Ausdruck des produzierten Metalls, nachdem es aus dem flüssigen Zustand in den festen Zustand überführt wird. Er ist das Grundprodukt aus dem Hochofen, das für die Herstellung von Walzprodukten und Gussstücken weiterverarbeitet wird.

Verschiedene Größen und Formen von Ingots

Ingots können verschiedene Größen und Formen aufweisen, abhängig von den geplanten Anwendungen und den Methoden, mit denen sie produziert werden. Die Form kann rechteckig, zylindrisch oder sogar pyramidenförmig sein, und die Größe kann von wenigen Kilogramm bis zu mehreren Tonnen reichen.

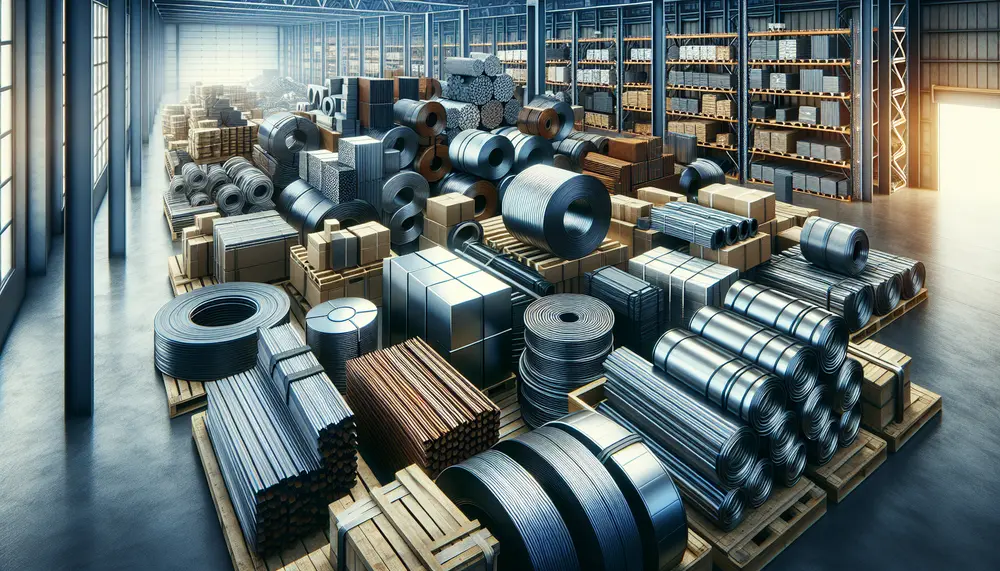

Anwendung von Ingots

Mit Ingots - diesen Paradebeispielen von Handelsmetallen ‒ können Hersteller weitere Produkte erstellen. Diese reichen von Bauteilen für Brücken und Gebäude, Schienen für Bahnen, Karosserieteilen für Fahrzeuge bis hin zu Rohren und Leitungen. Ohne Ingots wäre es nicht möglich, Stahl in all seinen Ausdrucksformen zu produzieren und zu nutzen.

Blog Posts with the term: Ingot

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Steel's origins trace back to meteoric iron and evolved with human discovery of smelting around 2500 BCE, leading from the Bronze Age into the Iron Age. The Bessemer Process in the mid-19th century revolutionized steel production, enabling mass production and...

HTS codes are essential for classifying steel products in international trade, determining tariffs and compliance with regulations. They require precise understanding due to their complexity and frequent updates influenced by global trade changes....

The article traces the history of steelmaking from early iron discoveries around 2,500 BCE to advanced techniques like Chinese cast iron production and Indian Wootz steel. It highlights key innovations such as smelting, forging by the Chalybes, and global influences...

The steel making degassing process is essential for producing high-quality steel by removing dissolved gases like hydrogen, nitrogen, and carbon monoxide to prevent material defects. Vacuum degassing enhances the mechanical properties of steel, crucial for applications in construction and manufacturing,...

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...

The article provides a detailed overview of the steelmaking process, starting from raw material extraction to final product creation. It emphasizes the importance of understanding each stage and the key materials involved—iron ore, coal, limestone, and scrap metal—to produce high-quality...

Steelmaking rolling is a crucial process that transforms raw steel into various usable forms by passing it through rollers to reduce thickness, improve uniformity, and achieve specific mechanical properties. The article details the stages of hot and cold rolling, the...

Steel manufacturing from scrap is a sustainable process that reduces environmental impact and conserves resources. It involves collection, separation, melting in an electric arc furnace, refining to remove impurities, adding alloy elements, and casting into new products; recycling steel offers...

JSW Steel employs advanced technology and sustainable practices in its steel manufacturing process, starting with the selection of raw materials like iron ore and coal. The company focuses on producing high-quality steel through a series of steps including melting, refining,...

India's steel industry utilizes rich iron ore resources and advanced technology, adopting innovative methods like automation for efficient production. Government policies support sustainable practices in this key economic sector that drives growth and employment....

The history of steel production spans over 4000 years, evolving from the creation of rudimentary iron tools to advanced high-strength steel. Key developments include smelting techniques in neolithic times, cementation in the 17th century, and major advancements during the Industrial...

A steel product is an item predominantly made of steel, known for its durability and versatility across industries, with a wide range of forms and applications. Understanding these products involves knowledge of the production process from raw materials to finished...