Load

Load

Was bedeutet "Load" in der Stahlproduktion und dem Stahlhandel?

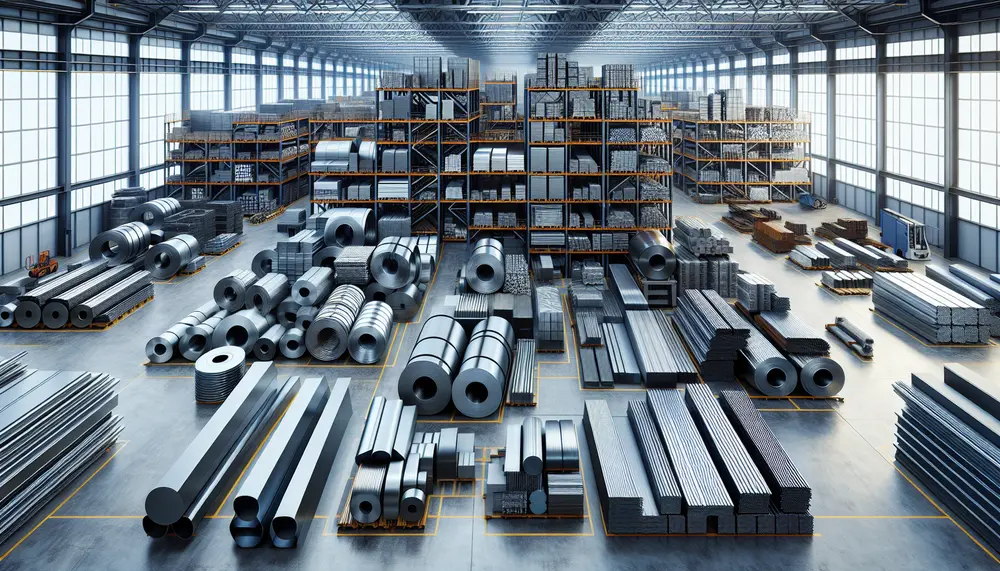

Der Begriff "Load" kann in der Stahlindustrie mehrere Bedeutungen haben, aber es bezieht sich im Allgemeinen auf die Menge an Stahl, die auf einmal transportiert oder verarbeitet wird.

Load in der Stahlproduktion

In einer Stahlproduktionsstätte beschreibt Load die Menge an Rohstoffen, die in einem Hochofen verarbeitet werden können. Ein hoher Load bedeutet, dass der Ofen effizient arbeitet und eine große Menge Stahl produziert.

Load im Stahlhandel

Im Stahlhandel dagegen bezieht sich Load auf die Menge an Stahl, die ein Schiff, ein LKW oder ein Zug auf einmal transportieren kann. Es ist eine wichtige Kennzahl in der Logistik und beeinflusst die Effizienz und Kosten des Stahltransports.

Warum ist "Load" wichtig?

Das Verständnis von Load ist wichtig, um die Effizienz der Stahlproduktion und des Stahlhandels zu maximieren. Je größer der Load, desto mehr Stahl kann produziert und transportiert werden, was zu niedrigeren Kosten pro Einheit führt.

Blog Posts with the term: Load

The steelmaking value chain is a complex process that transforms raw materials like iron ore, coking coal, and limestone into high-quality steel through strategic steps involving technological innovation to optimize efficiency and reduce environmental impact. Understanding this value chain helps...

Steel, an alloy primarily composed of iron and carbon, is a crucial material in modern construction and manufacturing due to its strength, flexibility, and durability. The process of making steel involves extracting iron ore, purifying it through beneficiation processes, smelting...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The steelmaking industry is increasingly using natural gas to improve efficiency and reduce environmental impact. Natural gas serves as a reducing agent in Direct Reduced Iron (DRI) processes, partially replaces coke in blast furnaces, fuels various types of industrial furnaces,...

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...

The electric arc furnace (EAF) revolutionizes steel making by melting recycled scrap with high-power electric arcs, offering a more environmentally friendly alternative to traditional blast furnaces. EAFs provide flexibility in production, reduce greenhouse gas emissions and energy consumption, and allow...

Romania's steel industry, led by LIBERTY Galati, is a key European player with strategic investments in technology and sustainability. The sector faces challenges like environmental impact but contributes significantly to the economy and innovation, aiming for carbon neutrality by 2030....

The manufacturing of steel balls is a complex process involving precise steps to produce high-quality products for various applications. It starts with selecting the right raw materials and includes forging, flashing, heat treating, grinding, lapping, and rigorous inspections to ensure...

The Open Hearth Process is a traditional steelmaking method that involves converting iron into steel using an open hearth furnace, which allows air to flow over the mixture and facilitates chemical reactions necessary for purification. This process utilizes regenerative heating...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

Lime is crucial in steelmaking, acting as a flux to remove impurities like phosphorus and sulfur, enhancing the quality of steel produced through processes such as EAF and BOF while also contributing to environmental sustainability by reducing emissions....

Steelmaking ladles are essential in the steel production process, designed to transport and refine molten metal while withstanding extreme temperatures and chemical corrosion. They come in various types tailored for specific functions such as transferring, treating, casting, and precise pouring...

The Basic Oxygen Furnace (BOF) process, developed in the mid-20th century by Robert Durrer, revolutionized steel production by using pure oxygen to convert molten iron into high-quality steel efficiently. This method involves charging a furnace with molten iron and scrap...

Steel production for vehicles involves transforming iron ore into various steel grades with specific properties, balancing strength and formability. Innovations in manufacturing techniques ensure high-quality steel that meets automotive industry standards. The journey of steel from raw material to vehicle component...