Metallurgy

Metallurgy

Einführung in die Metallurgie

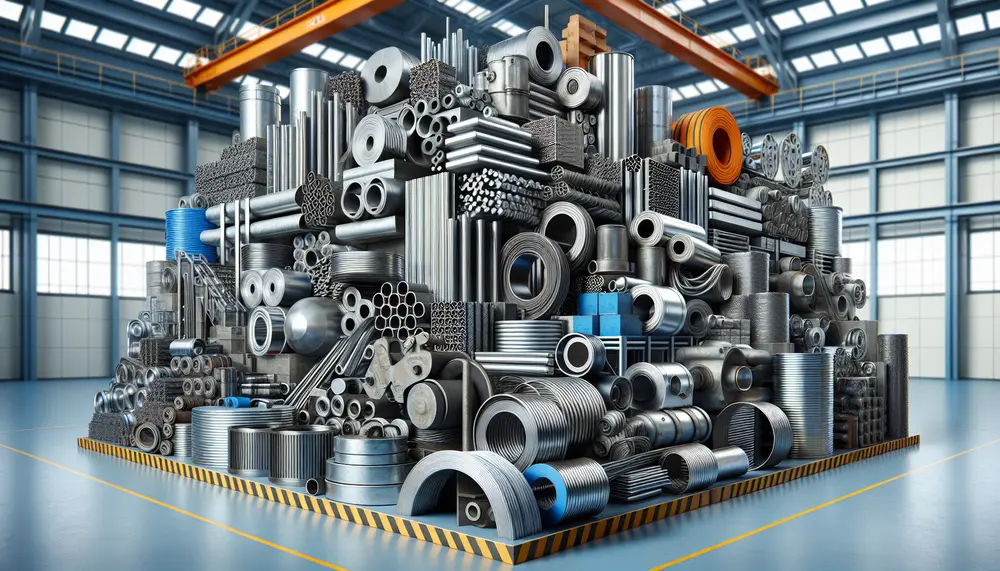

Die Metallurgie ist ein bedeutender Zweig der Materialwissenschaft. Sie befasst sich mit dem Studium von Metallverhalten und seiner Entwicklung vom Rohstoff (Erz) bis zum Endprodukt. Unsere alltäglichen Gegenstände wie Autos, Brücken, Münzen und sogar Küchenutensilien verdanken ihren Ursprung der Metallurgie.

Die Bedeutung der Metallurgie in der Stahlproduktion und im Stahlhandel

In der Stahlproduktion spielt die Metallurgie eine zentrale Rolle. Sie hilft bei der Umwandlung von rohem Eisenerz in nutzbaren Stahl. Stahl, eine Legierung aus Eisen und Kohlenstoff, ist das Ergebnis einer genauen Abfolge von metallurgischen Prozessen. Dieser fortlaufende Prozess bildet die Grundlage für die Stahlindustrie.

Arten der Metallurgie

Die Metallurgie ist in drei Haupttypen unterteilt: extractive Metallurgie, physical Metallurgie und mechanical Metallurgie. Die extractive Metallurgie konzentriert sich auf die Gewinnung von reinem Metall aus seinem Erz. Die physical Metallurgie untersucht physikalische Eigenschaften von Metallen. Und die mechanical Metallurgie ist mit der mechanischen Festigkeit und Belastbarkeit von Metallen beschäftigt.

Prozesse in der Metallurgie

Die Hauptprozesse in der Metallurgie umfassen Schmelzen, Verfeinern, Fabrikation und Behandlung von Metallen. Diese Prozesse sind nötig, um das richtige Maß an Haltbarkeit, Festigkeit und anderen benötigten Eigenschaften in Stahl zu erzeugen.

Schlussgedanken

Die Metallurgie ist das Herz der Stahlproduktion und des Stahlhandels. Ohne sie wäre die Produktion von robustem, langlebigem und hochwertigem Stahl nicht möglich. Durch das tiefe Verständnis dieser Wissenschaft können wir fortschrittliche stählerne Gegenstände und Strukturen herstellen, die unser modernes Leben prägen.

Blog Posts with the term: Metallurgy

Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel. The industry emphasizes sustainability by using additives and recycled materials while ensuring...

The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses...

Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF), followed...

The Bessemer process, developed by Henry Bessemer in the 1850s, revolutionized steel production by efficiently removing impurities from molten pig iron using blown air and enabling mass production. This innovation significantly reduced costs and time for steel manufacturing, facilitating industrial...

The article traces the evolution of steelmaking from ancient techniques to significant medieval innovations, highlighting early methods like iron carburization and bloomery processes that evolved into more efficient practices with the introduction of blast furnaces. It also covers Renaissance advancements...

The Open Hearth Process is a traditional steelmaking method that involves converting iron into steel using an open hearth furnace, which allows air to flow over the mixture and facilitates chemical reactions necessary for purification. This process utilizes regenerative heating...

Japan's steel industry rose from the post-WWII era to become a global leader through strategic investments in technology, quality control, and export-oriented policies. Key factors for this success include R&D commitment, high-quality standards, advantageous locations for trade routes, skilled workforce...

The article explains the importance of understanding a steelmaking flow chart, which outlines each step from raw material preparation to final products, aiding in efficiency and productivity. It details key components like raw materials (iron ore, limestone, coal), primary steps...

The article traces the history of steelmaking from early iron discoveries around 2,500 BCE to advanced techniques like Chinese cast iron production and Indian Wootz steel. It highlights key innovations such as smelting, forging by the Chalybes, and global influences...

Japanese steelmaking blends ancient traditions with modern innovations, producing some of the world's finest steel. This article explores its rich history from early Tatara furnaces to advanced techniques today, highlighting the craftsmanship and enduring legacy of Japanese steel production....

The Basic Oxygen Furnace (BOF) process, developed in the mid-20th century by Robert Durrer, revolutionized steel production by using pure oxygen to convert molten iron into high-quality steel efficiently. This method involves charging a furnace with molten iron and scrap...

Nucor revolutionizes steelmaking with its Electric Arc Furnace (EAF) process, transforming recycled scrap into high-quality steel while prioritizing sustainability and efficiency. This innovative approach reduces carbon emissions, enhances energy efficiency, and offers tailored solutions for industries like automotive and construction....

Steelmaking ladles are essential in the steel production process, designed to transport and refine molten metal while withstanding extreme temperatures and chemical corrosion. They come in various types tailored for specific functions such as transferring, treating, casting, and precise pouring...

The article provides an in-depth look at the role of steel products across various industries, highlighting their diverse applications and importance. It covers the basics of steel production, compares uses in different sectors, explains differences between hot-rolled and cold-rolled steel,...

The article explores global steel production, focusing on the Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF) methods, highlighting their processes, environmental impacts, and adaptability. It emphasizes how sustainability trends are reshaping these techniques while secondary steelmaking refines quality...